Construction method for engineered Escherichia coli strain capable of producing sialyllactose

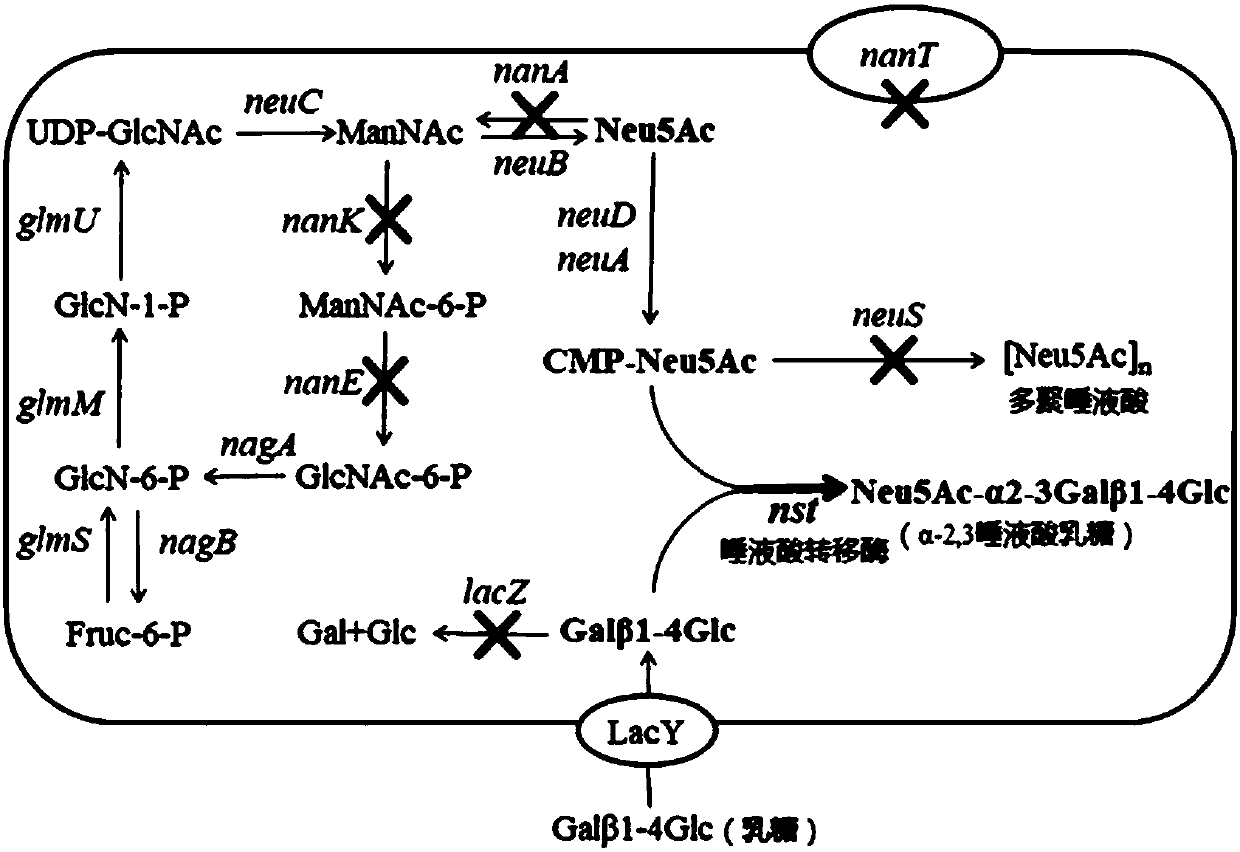

A technology of sialyllactose and Escherichia coli, which is applied in the field of cell-catalyzed synthesis of sialyllactose, can solve the problems of large disturbance of chassis cells and achieve low cost, simplified production methods and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Strain: Escherichia coli K1 (CMCC number 44277, O2:K1:H4).

[0049] 1 polysialyltransferase gene (neuS) knockout strain E.coli K1-ΔneuS

[0050] The neuS gene knockout process and verification results are as follows:

[0051]The Escherichia coli K1 strain containing plasmid pKD46 expresses three recombinant proteins of bacteriophage γ after arabinose induction, thus having the ability of homologous recombination; using pKD3 as a template, the designed primers (neuS-H1-P1 and neuS-H2-P2 ) has a neuS gene homology arm of about 50 bp at the 5′ end, and an amplification primer at the 3′ end to amplify the chloramphenicol gene containing FRT sites on both sides, and then electrotransform the linear fragment into E.coli K1 after purification (pKD46) Competent cells, positive transformants were screened by chloramphenicol plate and colony PCR. Use high temperature to eliminate the temperature-sensitive plasmid pKD46, electrotransform the plasmid pCP20 expressing Flp recombin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com