Anisotropic polyvinyl alcohol aerogel material and preparation method thereof

A polyvinyl alcohol, anisotropic technology, applied in the field of polyvinyl alcohol airgel materials, can solve problems such as limiting the scope of use of PVA airgel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

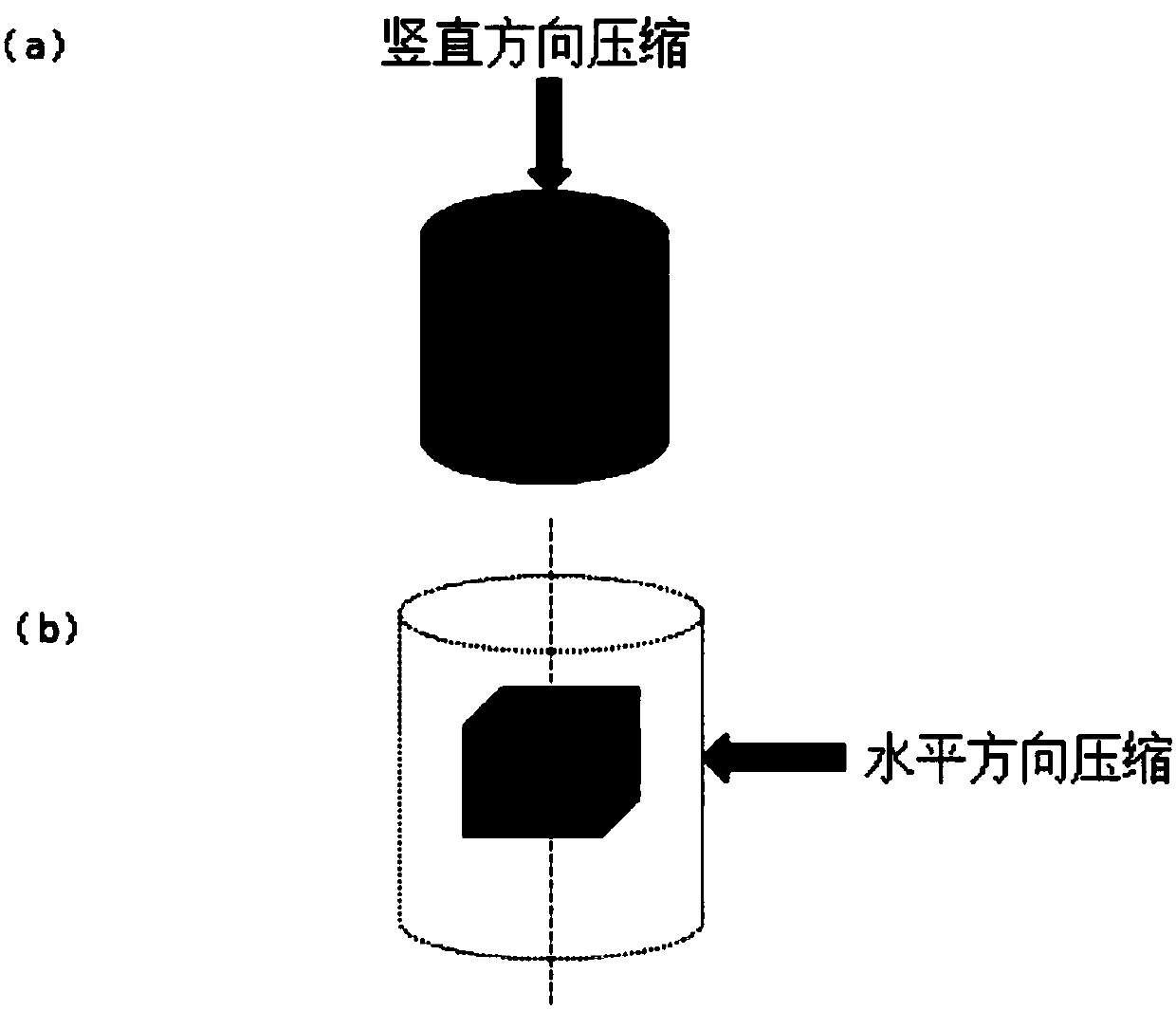

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of polyvinyl alcohol aerogel by freezing method

[0040] 1. Prepare a 6wt% aqueous solution of PVA

[0041] Take 10g of polyvinyl alcohol, add 156.7g of deionized water, fully swell, heat and stir to dissolve the polyvinyl alcohol.

[0042] 2. Preparation of polyvinyl alcohol aerogel by freezing method

[0043] The 6wt% aqueous PVA solution prepared in step 1 was poured into the mold. Prepare a mixture of dry ice and ethanol as a freezing liquid in a large container, and prepare a freezing liquid with a temperature of -70°C according to the amount of dry ice added. Put a mold containing a 6wt% PVA aqueous solution into a container containing a freezing liquid at -70°C, the liquid level of the freezing liquid is higher than the liquid level in the mold, and the freezing direction from the periphery of the mold to the center of the mold is realized.

[0044] When the solution in the mold is completely frozen into a solid, put it in a freeze dryer for freeze ...

Embodiment 2

[0045] Example 2 Preparation of polyvinyl alcohol aerogel by freezing method

[0046] 1. PVA aqueous solution with a concentration of 8wt%

[0047] Take 10 g of polyvinyl alcohol, add 115 g of deionized water, fully swell, heat and stir to dissolve the polyvinyl alcohol.

[0048] 2. Preparation of polyvinyl alcohol aerogel by freezing method

[0049] The PVA aqueous solution with a concentration of 8 wt% prepared in step 1 is poured into the mold. Prepare a mixture of dry ice and ethanol as a freezing liquid in a large container, and prepare a freezing liquid with a temperature of -60°C according to the amount of dry ice added. Put the mold containing the 8wt% PVA aqueous solution into the container containing the freezing liquid at -60°C, the liquid level of the freezing liquid is higher than the liquid level in the mold, and the freezing direction from the periphery of the mold to the center of the mold is realized.

[0050] When the solution in the mold is completely frozen into a ...

Embodiment 3

[0051] Example 3 Preparation of polyvinyl alcohol aerogel by freezing method

[0052] 1. PVA aqueous solution with a concentration of 10wt%

[0053] Take 10g of polyvinyl alcohol, add 90g of deionized water, fully swell, heat and stir to dissolve the polyvinyl alcohol.

[0054] 2. Preparation of polyvinyl alcohol aerogel by freezing method

[0055] Pour the 10wt% PVA aqueous solution prepared in step 1 into the mold. Prepare a mixture of dry ice and ethanol as a freezing liquid in a large container, and prepare a freezing liquid with a temperature of -65°C according to the amount of dry ice added. The mold containing the PVA aqueous solution with a concentration of 10wt% is placed in a container containing a freezing liquid at -65°C. The liquid level of the freezing liquid is higher than the liquid level in the mold to realize the freezing direction from the periphery of the mold to the center of the mold.

[0056] When the solution in the mold is completely frozen into a solid, put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com