Static pressure self-unloading cement transport ship

A transport ship and self-unloading technology, which is applied in the direction of transportation and packaging, ship accessories, cargo handling equipment, etc., can solve the problem of parallel unloading, stable and dust-free unloading, fast unloading, and the health of dust-prone loading and unloading workers. , pollute the environment and other issues, to achieve the effect of not polluting the water area and port environment, improving the efficiency of unloading ships, and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

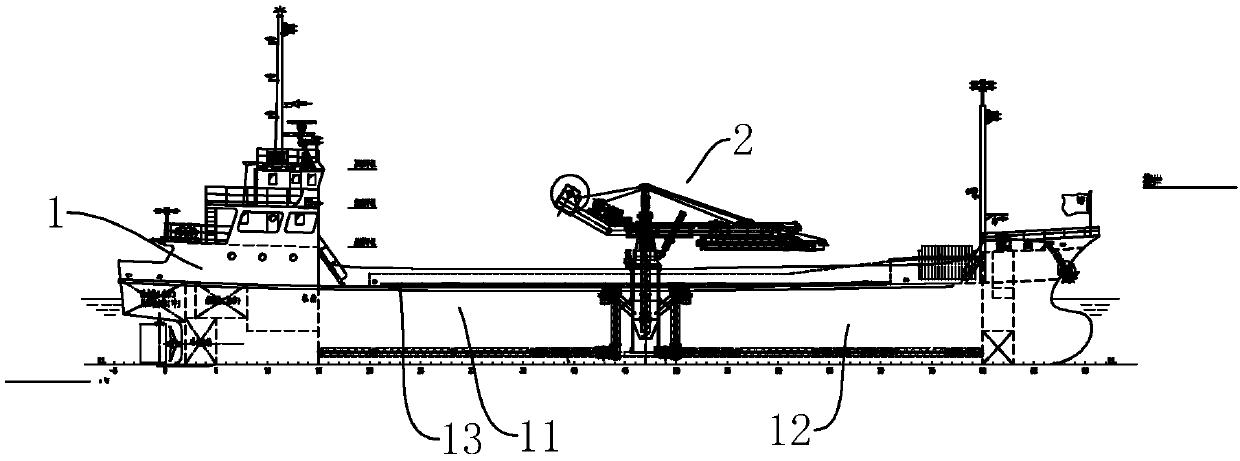

[0038] A static pressure self-unloading cement carrier, such as figure 1 and figure 2 As shown, there is a transport ship having a cargo area 10 comprising a first cargo tank 11 and a second cargo tank 12 .

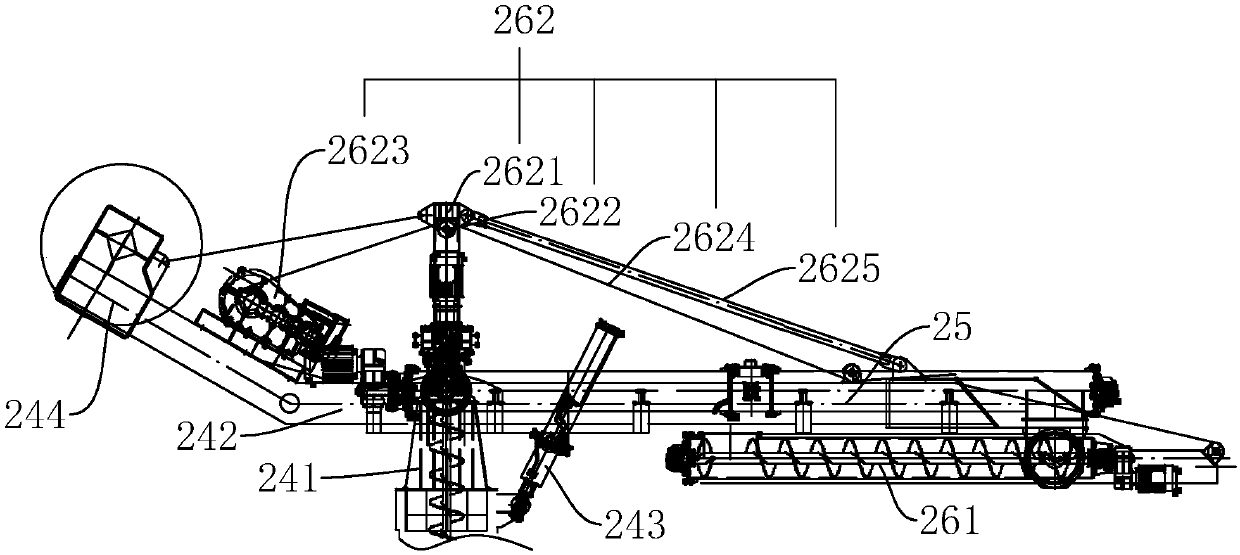

[0039]A cargo unloading device 2 is provided in the cargo hold area 10, and the cargo unloading device 2 includes a bilge conveying screw mechanism 21 for horizontally conveying goods, a primary lifting conveying screw mechanism 22 connected to the bilge conveying screw mechanism 21 for vertically conveying goods, The secondary lifting and conveying screw mechanism 23 connected to the primary lifting and conveying screw mechanism 22, the luffing jib mechanism 24 installed on the secondary lifting and conveying screw mechanism 23, the luffing jib mechanism 24 installed on the luffing jib mechanism 24 Driving the amplitude-changing conveying screw mechanism 25 and the land-landing conveying screw mechanism 26 connected to the output end of the amplitude-changing conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com