Water permeable brick pressing molding equipment

A technology for pressing and forming water-permeable bricks, applied in the directions of forming indenters, ceramic forming machines, manufacturing tools, etc., can solve the problems of insufficient machining accuracy, short service life, large body deformation, etc., to improve machining accuracy, accurate positioning, stress reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

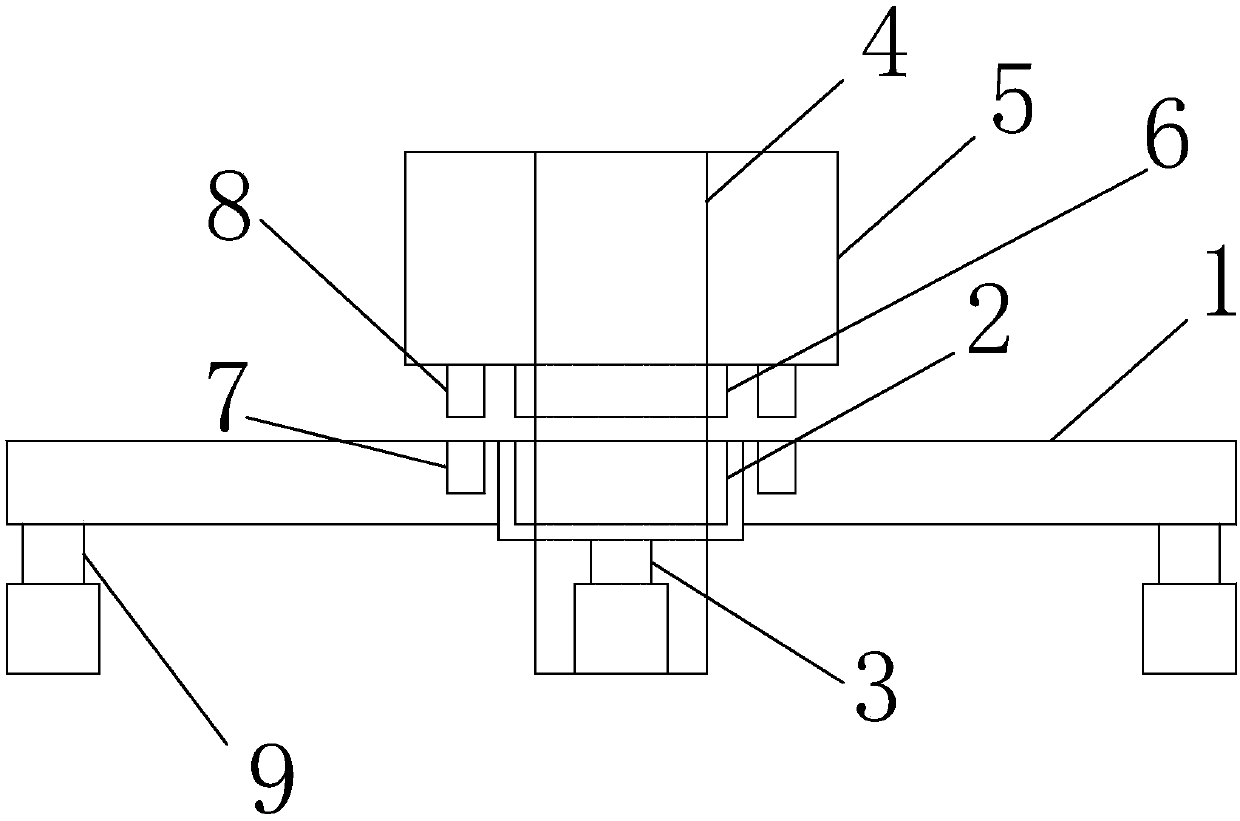

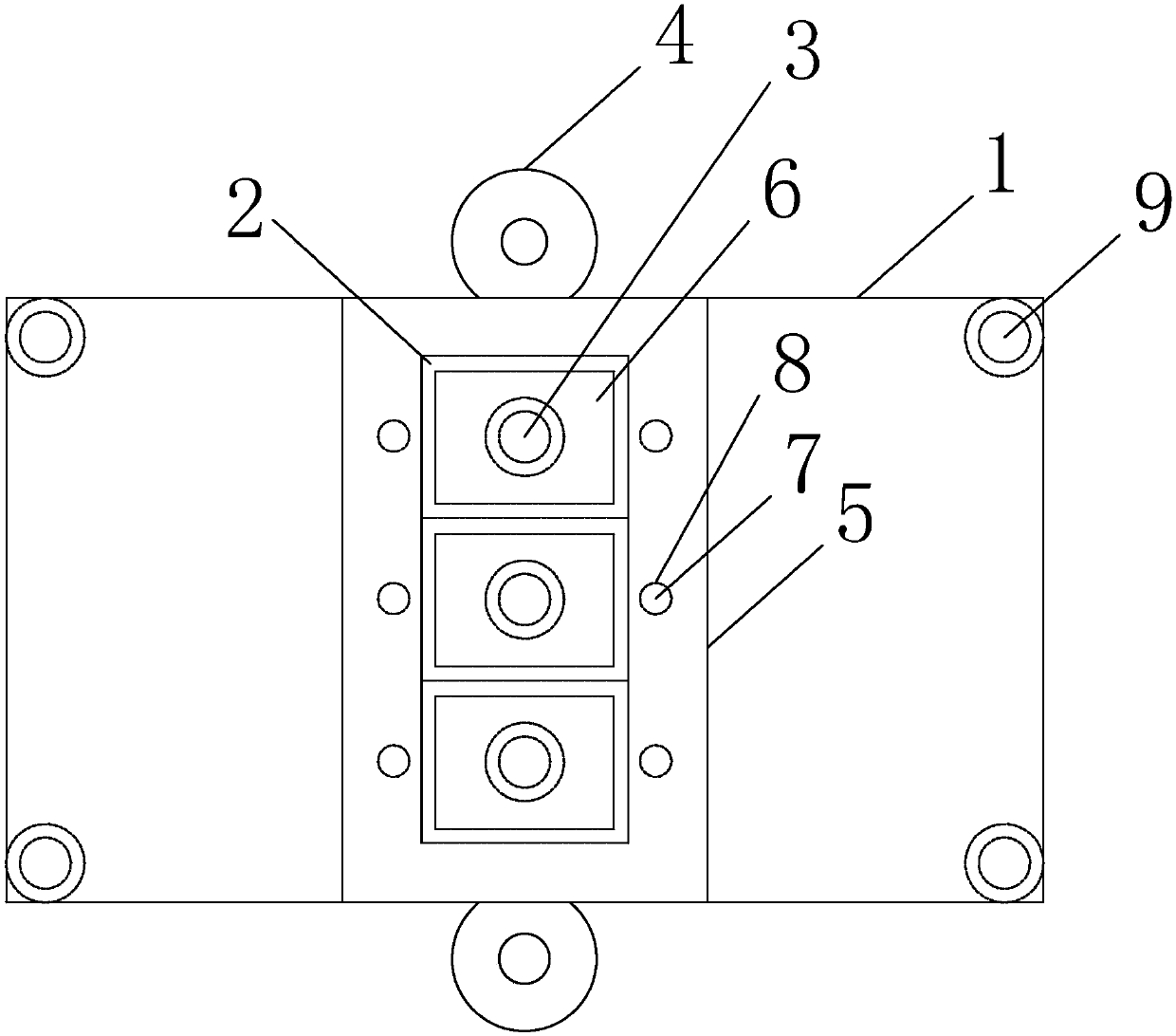

[0013] refer to Figure 1-Figure 2 , a permeable brick pressing molding equipment of the present invention, comprising a molding workbench 1, the middle of the molding workbench 1 is hollowed out and a movable molding bottom mold 2 is arranged, and a mold buffer support column is arranged under the molding bottom mold 2 3. Columns 4 are arranged on both sides of the forming workbench 1, a hydraulic movable beam 5 is arranged above the forming workbench 1, and the hydraulic movable beam 5 is sleeved on the column 4, and the hydraulic movable beam 5 is arranged below There is a forming top mold 6 that matches the forming bottom mold 2, and positioning grooves 7 are also provided on both sides of the forming bottom mold 2, and positioning grooves 7 that match the positioning grooves 7 are also provided on both sides of the forming top mold 6. Column 8. It adopts hydraulic forming, which has a larger pressing force, the pressing action is softer, more stable, and the pressing for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com