A functionalized multi-acid ionic liquid catalyst, preparation method and method for catalytically synthesizing isobornyl acetate with it

A technology of isobornyl acetate and ionic liquid, applied in physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, preparation of carboxylate, etc., can solve the problem of low yield of isobornyl acetate , low esterification reaction rate, poor thermal stability and other problems, to achieve the effect of simple synthesis method, good stability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of functionalized multi-acid ionic liquid catalyst, described method comprises the following steps:

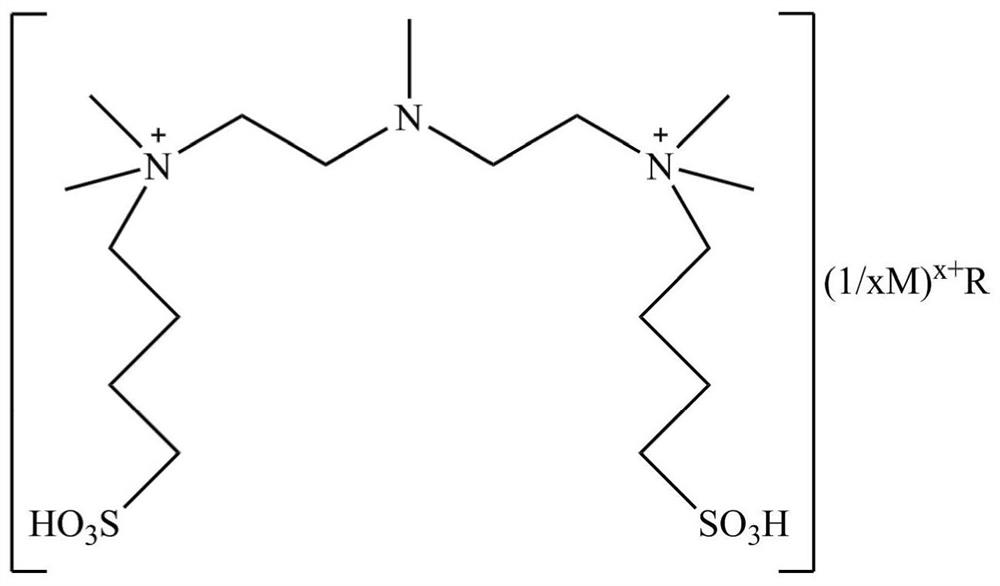

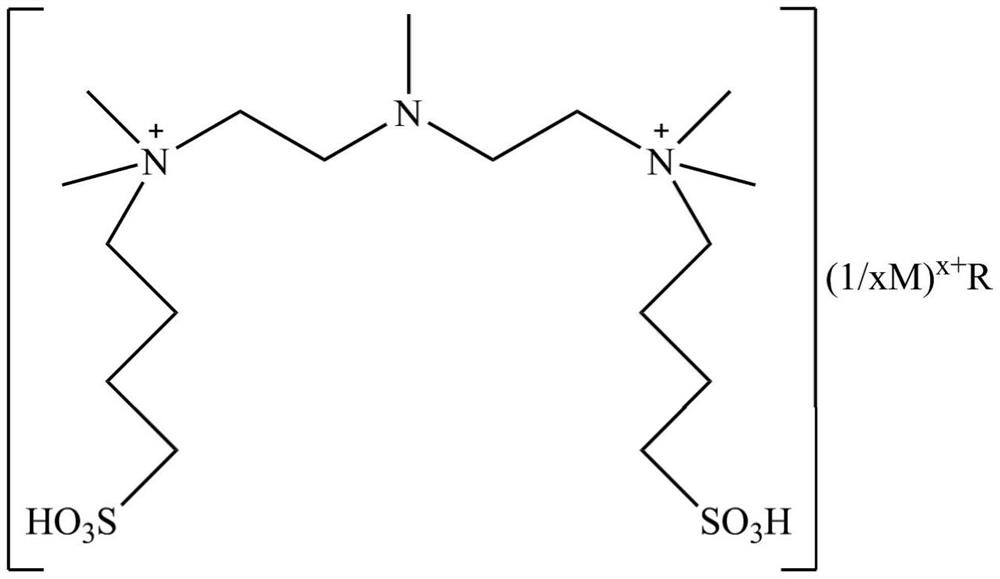

[0032] (1) Take a certain amount of pentamethyldiethylenetriamine (0.2mol) and 1,4-butyl sultone (0.4mol) in a round bottom flask, slowly heat up to 60°C under stirring, and react quickly to obtain white solid. The obtained solid was washed three times with ethyl acetate and filtered, then vacuum-dried at 80° C. for 12 h, and the obtained white solid was an ylide.

[0033] (2) Take a certain amount of ylide (0.1 mol) and place it in a round bottom flask, and place it in a water bath at 80°C. Take 0.1mol of phosphotungstic acid (H 3 PW 12 o 40 ) was dissolved in distilled water and added dropwise to a round bottom flask, stirred and refluxed for 18h. After the reaction, the water was distilled off under reduced pressure to obtain a light yellow solid, which was washed three times with ether and toluene in sequence, and dried in vacuum at...

Embodiment 2

[0038] A method for synthesizing isobornyl acetate by functionalization multi-acid ionic liquid catalysis, comprises the following steps: in reactor, add acetic acid 18.02g (0.3mol) successively, camphene 13.62g (0.1mol) and embodiment [Bis-Bs-PMDETA](1 / 2Zn)HSiW prepared in 1 12 o 40 Catalyst 1.84g (accounting for 7wt% of raw material total mass), stirring and heating up to reaction temperature 60 ℃, constant temperature reaction 3h, the transformation rate of camphene is 92%, the selectivity of isobornyl acetate is 96%, and isoformyl acetate The yield of brain ester was 88%.

Embodiment 3

[0040] A method for synthesizing isobornyl acetate by functionalization multi-acid ionic liquid catalysis, comprises the following steps: in reactor, add acetic acid 6.01g (0.1mol) successively, camphene 27.25g (0.2mol) and embodiment [Bis-Bs-PMDETA](1 / 2Cu)PMo prepared in 1 12 o 40 Catalyst 0.98g (accounting for 5wt% of raw material gross mass), stirring and heating up to reaction temperature 100 ℃, constant temperature reaction 1h, the conversion rate of camphene is 44%, the selectivity of isobornyl acetate is 89%, and isoformyl acetate The yield of brain ester was 39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com