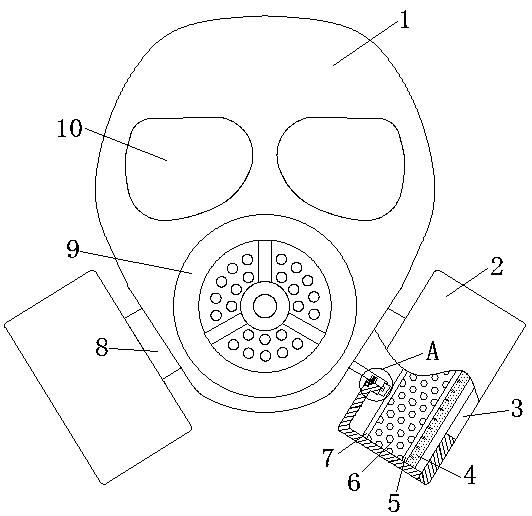

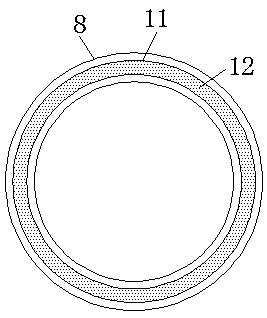

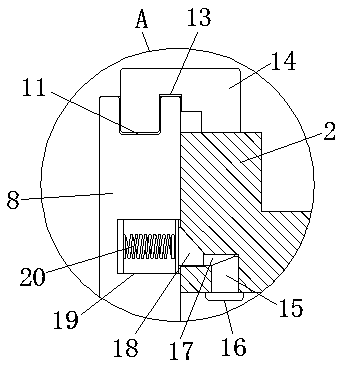

Gas mask with high tightness

A gas mask and sealing technology, which is applied in the direction of breathing masks, life-saving equipment, respiratory protection devices, etc., can solve the problems of insufficient sealing, inconvenient replacement of filter boxes, etc., and achieve the effect of easy replacement, simple disassembly and improved sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of formaldehyde scavenger, the method comprises the following steps:

[0027] Step 1. Weigh 9.37g of zinc nitrate hexahydrate and dissolve it in 14g of deionized water to make a salt solution containing zinc. Slowly drop the solution onto the alumina carrier (volume ratio 4:3), and then let it stand at room temperature Aging for 5 hours, drying at 100°C for 6 hours, and roasting at 400°C for 8 hours to obtain an adsorbent precursor containing zinc oxide;

[0028] Step 2, take by weighing 9.35g copper nitrate trihydrate and be dissolved in 14g deionized water, be made into the saline solution containing copper, slowly drip this solution on the above-mentioned obtained adsorbent precursor containing zinc oxide (volume ratio 1: 1), then standing and aging at room temperature for 5 hours, drying at 100°C for 6 hours, and roasting at 400°C for 8 hours to obtain a bimetallic formaldehyde adsorbent precursor containing copper oxide and zinc oxide;

[0029...

Embodiment 2

[0034] Step 1. Weigh 9.37g of zinc nitrate hexahydrate and dissolve it in 14g of deionized water to make a salt solution containing zinc. Slowly drop the solution onto the alumina carrier (volume ratio 3:4), and then let it stand at room temperature Aging for 5 hours, drying at 100°C for 6 hours, and roasting at 400°C for 8 hours to obtain an adsorbent precursor containing zinc oxide; the rest of the preparation was the same as in Example 1.

Embodiment 3

[0036] Step 1. Weigh 9.37g of zinc nitrate hexahydrate and dissolve it in 14g of deionized water to make a salt solution containing zinc. Slowly drop the solution onto the alumina carrier (volume ratio 4:3), and then let it stand at room temperature Aging for 5 hours, drying at 100°C for 6 hours, and roasting at 400°C for 8 hours to obtain an adsorbent precursor containing zinc oxide; the rest of the preparation was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com