Adjustable annular jet pump

An annular jet and fluid tube technology, applied in the field of jet pumps, can solve the problems of reduced pressure ratio and boosting capacity, inability of the annular jet pump to operate, unable to meet working requirements, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

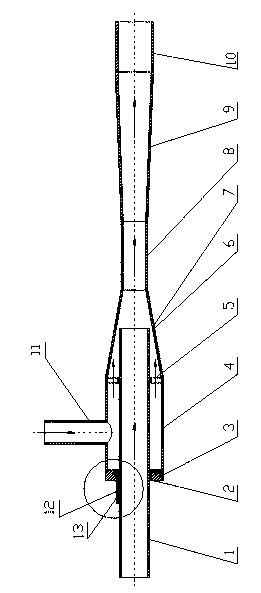

[0020] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , figure 2 , Figure 4 As shown, an adjustable annular jet pump includes a rectification assembly, a mixing pipe 7, a throat pipe 8, a diffuser pipe 9, and an outlet pipe 10 connected in sequence. The rectification assembly includes a rectification pipe 4, a suction fluid pipe 1 and a working fluid Tube 11, the rectifying tube 4 communicates with the working fluid tube 11, and one end of the rectifying tube 4 is provided with an end cover 3, and the suctioned fluid tube 1 passes through the end cover 3 and can move axially relative to the end cover 3. A scale 12 is provided on the outer end of the end cap 3 , and a pointer 13 is provided on the pipe 1 for the sucked fluid. The end of the suctioned fluid pipe 1 and the mixing pipe 7 form a working nozzle 6 . According to the different scales on the scale corresponding to the pointer, the position of the suctioned f...

Embodiment 2

[0026] Such as figure 1 , image 3 , Figure 4 As shown, an adjustable annular jet pump includes a rectification assembly, a mixing pipe 7, a throat pipe 8, a diffuser pipe 9, and an outlet pipe 10 connected in sequence. The rectification assembly includes a rectification pipe 4, a suction fluid pipe 1 and a working fluid Tube 11, the rectifying tube 4 communicates with the working fluid tube 11, and one end of the rectifying tube 4 is provided with an end cover 3, and the suctioned fluid tube 1 passes through the end cover 3 and can move axially relative to the end cover 3. A scale 12 is provided on the outer end of the end cap 3 , and a pointer 13 is provided on the pipe 1 for the sucked fluid. The end of the suctioned fluid pipe 1 and the mixing pipe 7 form a working nozzle 6 . According to the different scales on the scale corresponding to the pointer, the position of the suctioned fluid channel and the flow area of the nozzle can be determined, so as to determine the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com