Preparation method of high-anticorrosion self-cleaning super-hydrophobic phosphating composite film on surface of zinc coating

A composite film layer and self-cleaning technology, which is applied in the coating process of metal materials, etc., can solve the problems of high equipment requirements, toxic raw materials, complex process engineering, etc., and achieve improved comprehensive performance, improved corrosion resistance, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Take ZnO 1.2 g, NaNO 3 15 g and 85 wt% H 3 PO 4 11 ml was added to 1 L of water, and the pH was adjusted to 3.0 with NaOH to obtain a phosphating solution; Ce(NO 3 ) 3 2g and H 2 o 2 20 ml was prepared into 1 L of aqueous solution to obtain a rough modified solution;

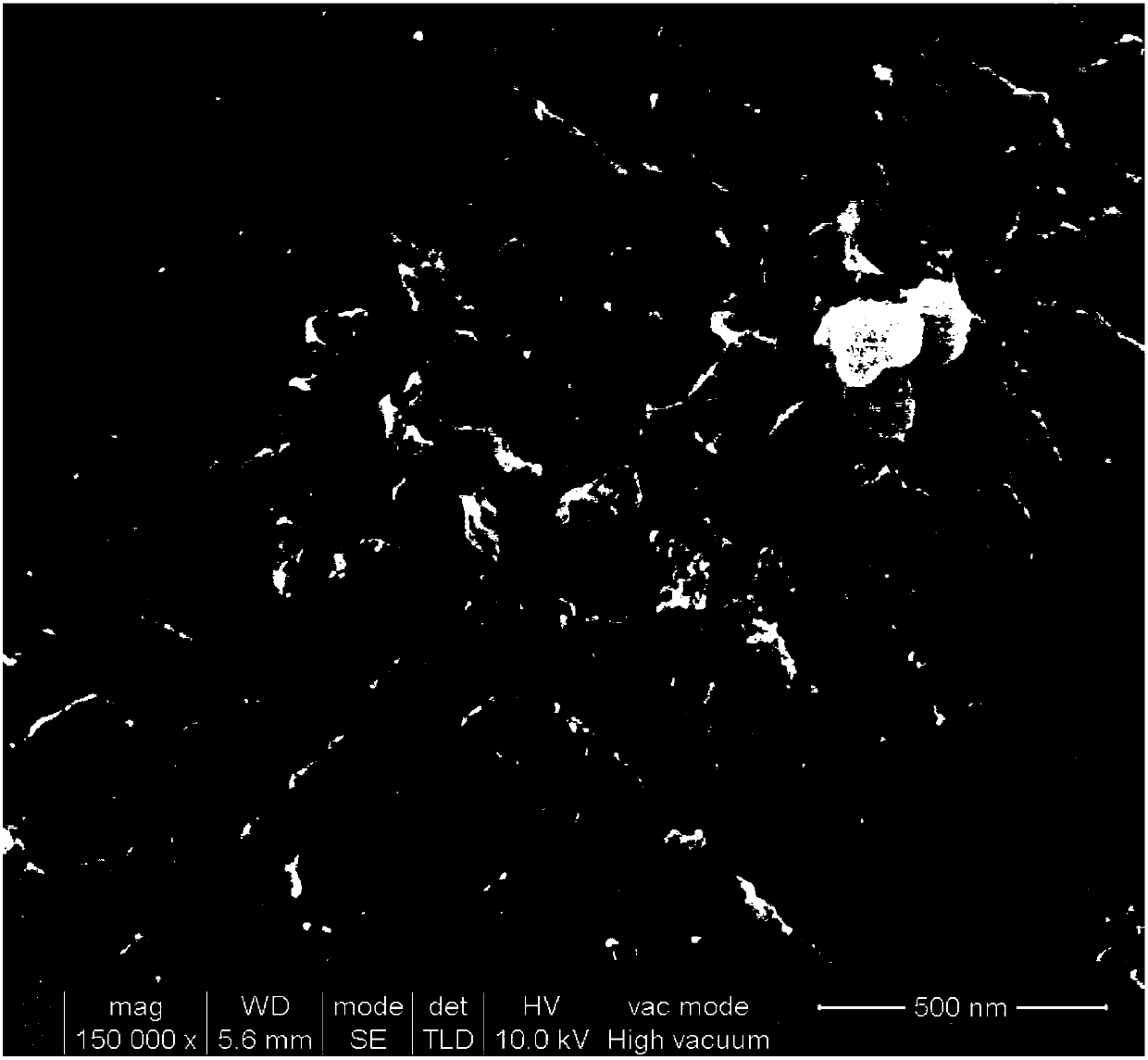

[0045] (2) Soak the zinc plate in the phosphating solution at 45 °C in a constant temperature water bath for 5 minutes, and then soak it in the rough modification solution for 2 minutes at room temperature to obtain a zinc plate with a phosphate film layer. The phosphate film layer is Composite rough structure phosphating film with nanostructure and microstructure, the thickness of phosphate film layer is 15μm;

[0046] (3) Immerse the zinc plate with zinc phosphate film in the ethanol solution of 100 ml / L hexamethyldisilazane to modify for 30 minutes, and obtain a highly corrosion-resistant self-cleaning superhydrophobic phosphating with a thickness of 20 μm on the surface of the zinc plate...

Embodiment 2

[0052] (1) Take ZnO 1.2 g, NaNO 3 15 g and 85 wt% H 3 PO 4 11 ml was added to 1 L of water, and the pH was adjusted to 3.0 with NaOH to obtain a phosphating solution; Ce(NO 3 ) 3 2g and H 2 o 2 20 ml was prepared into 1 L of aqueous solution to obtain a rough modified solution;

[0053] (2) First put the zinc plate into the phosphating solution of 45 °C in a constant temperature water bath and soak for 5 minutes, and then soak it in the rough modification solution for 30 seconds at room temperature to obtain a zinc plate with a phosphate film layer. Composite rough structure phosphating film with nanostructure and microstructure, the thickness of phosphate film layer is 25μm;

[0054] (2) The zinc plate with phosphate film layer was immersed in 100 ml / L hexamethyldisilazane ethanol solution for 30 min to obtain a highly corrosion-resistant self-cleaning superhydrophobic phosphating composite film layer with a thickness of 30 μm.

[0055] The hydrophobic angle of the...

Embodiment 3

[0058] (1) Take 2.0 g of ZnO, NaNO 3 15 g and 85 wt% H 3 PO 4 Add 15 ml to 1 L of water, adjust the pH to 3.0 with NaOH to obtain a phosphating solution; take Ce(NO 3 ) 3 5 g and H 2 o 2 20 ml was prepared into 1 L of aqueous solution to obtain a rough modified solution;

[0059] (2) First put the zinc plate into the phosphating solution of 45 °C in a constant temperature water bath and soak for 5 minutes, and then soak it in the rough modification solution for 2 minutes at room temperature to obtain a zinc plate with a phosphate film layer. Composite rough structure phosphating film with nanostructure and microstructure, the thickness of the phosphate film layer is 20μm;

[0060] (3) Immerse the zinc plate with the zinc phosphate film in the ethanol solution of 100 ml / L hexamethyldisilazane for 30 minutes to obtain a highly corrosion-resistant self-cleaning superhydrophobic phosphating composite film with a thickness of about 25 μm .

[0061] The prepared high-cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com