Automatic quality detection foil winding machine and on-line detection system thereof

A foil winding machine and quality technology, applied in the field of automatic quality detection foil winding machine and its online detection system, can solve the problems of low accuracy, easy generation of wrinkles, low hardness of layer insulation tape, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

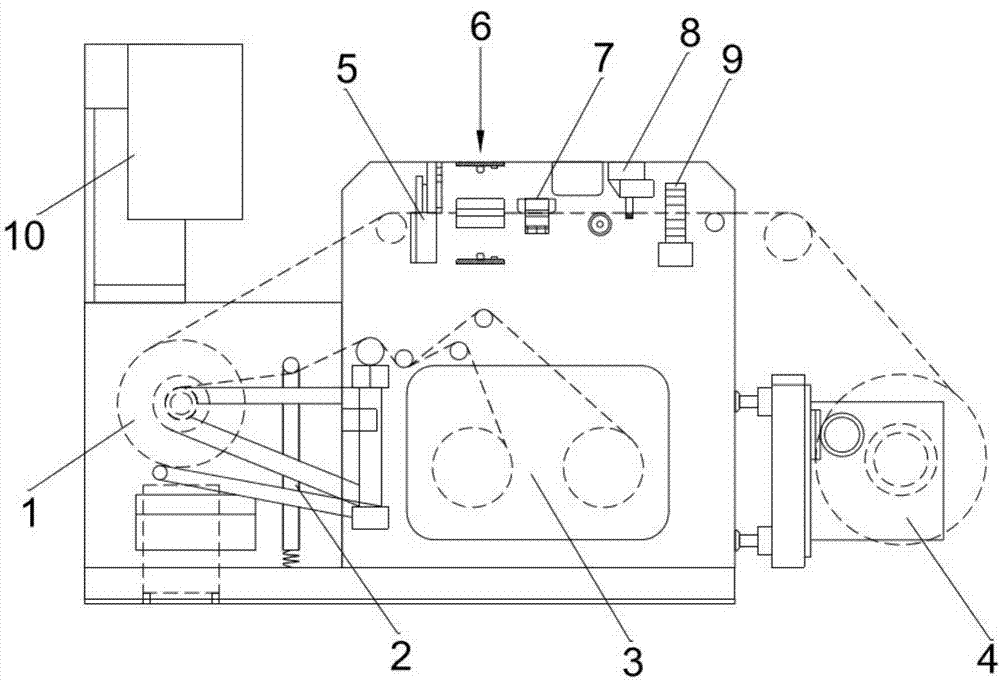

Embodiment 1

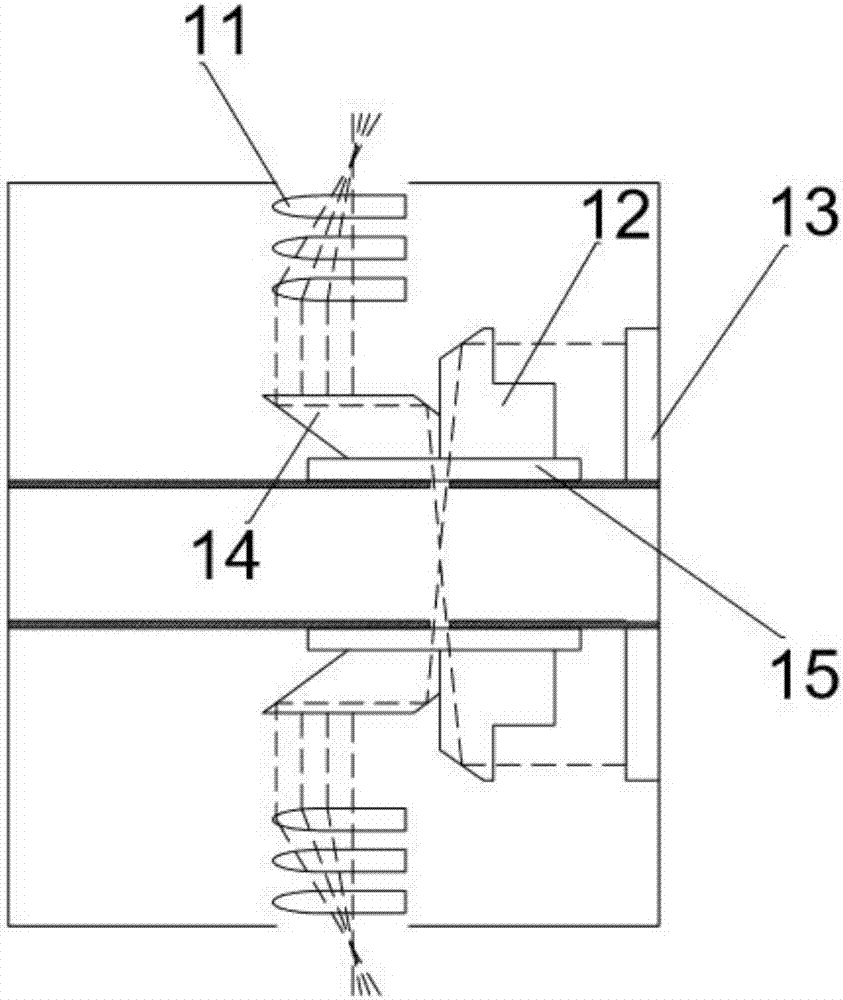

[0037] see Figure 1-4 As shown, an automatic quality detection foil winding machine mainly includes: a winding host 1, a foil uncoiling device 4 and a layer insulation uncoiling device 3, and the winding host 1, the foil uncoiling device 4 and the layer insulation uncoiling device 3 are all connected On the main frame, a deburring device 9, a deviation correcting device 8, a cleaning device 7 and a shearing device 5 are sequentially arranged between the foil uncoiling device 4 and the winding main machine 1. There is also a detection device 6 between them. The detection device 6 includes a detector and two receivers. The two receivers are respectively arranged above and below the detector. Controlled by the electric control box 10, the foil on the foil unwinding mechanism 4 The layer insulation tape on the tape and layer insulation unwinding device 3 is wound on the winding main machine 1 in turn. After the foil tape has been deburred and cleaned, the detection device 6 check...

Embodiment 2

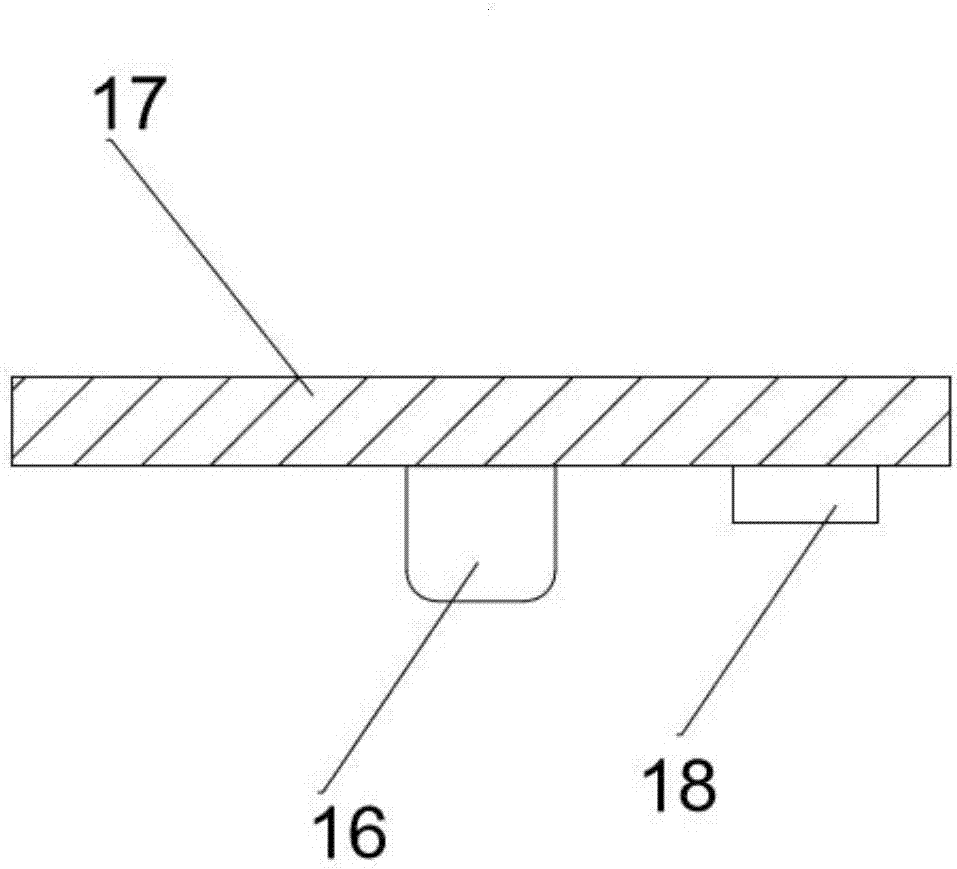

[0043] see Figure 5 As shown, an online detection system for an automatic quality detection foil winding machine includes the following steps:

[0044] Step 1: Image acquisition: the linear array CCD16 continuously receives the light spot reflected on the foil strip;

[0045] Step 2: Information transmission: the Wi-Fi chip 18 transmits the image information to the PC and inputs it into the MATLAB software;

[0046] Step 3: Image processing: process the image in MATLAB software, identify the defect site on the foil, and calculate the defect area;

[0047] Step 4: Presentation of results: Present the defect area as a percentage data, compare with the qualified standard data, and judge whether the product quality is qualified.

[0048]Preferably, the image processing described in step 3 includes grayscale processing, converting the true color image of the foil strip into a black and white image, so as to quickly identify the location and occupied area of the defect in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com