Side-blowing type vertical gas boiler

A gas-fired boiler, side-blown technology, applied in steam boilers, combustion methods, exhaust gas devices, etc., can solve the problem that the boiler flame cannot be completely cooled by water, the layout of the boiler's smoke outlet pipe seat is difficult, and the boiler height It is difficult to control and other problems to achieve the optimal utilization of heating area, good water cooling effect, and compact boiler structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

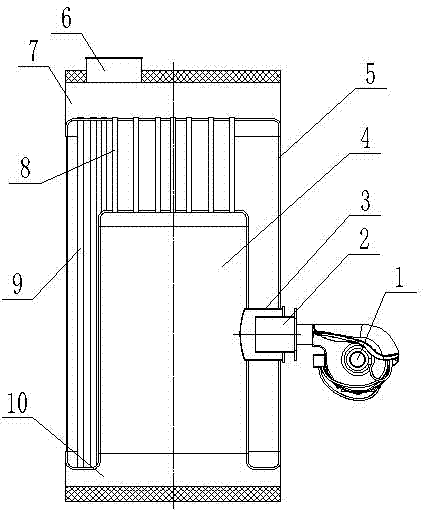

[0011] like figure 1 As shown, a side-blowing vertical gas boiler includes a pot shell 5, the center of which is a furnace 4, the top of the furnace 4 is an upper smoke box 7, the bottom is a lower smoke box 10, and the side is a threaded smoke pipe 9. The bottom of the furnace 4 is connected to the lower smoke box 10, and the lower smoke box 10 is connected to the upper smoke box 7 through a threaded smoke pipe. The top of the pot shell 5 is provided with a smoke outlet 6 connected to the upper smoke box 7. Pull struts 8 are arranged between the upper smoke boxes 7 . The burner 1 is arranged on the side of the furnace 4, and the burner 1 communicates with the inside of the furnace 4 through the burner connecting pipe 2, and the burner connecting pipe 2 is arranged in the connecting pipe protective cover 3.

[0012] When the boiler is burning, the burner 1 is sprayed into the furnace 4 through the burner connecting pipe 2 for combustion, and the flue gas generated by the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com