Air-cooled chiller

A water chiller, air-cooled technology, applied in the field of air-cooled chillers, can solve the problems of higher and higher water temperature, affect the cooling effect, loss of process water, etc., achieve good water cooling effect, optimize water cooling effect, and save process water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

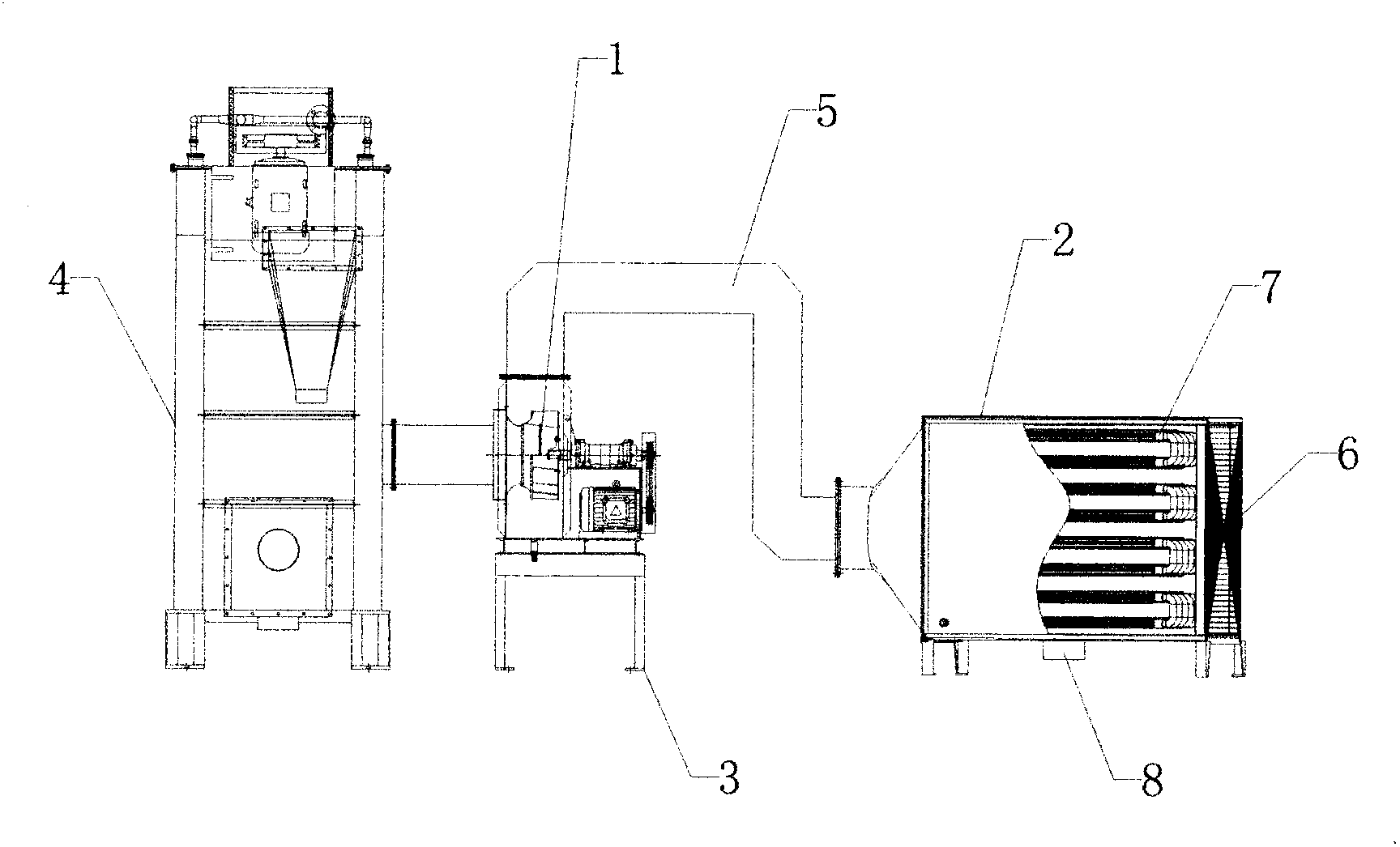

[0011] like figure 1 As shown, an air-cooled water chiller includes a fan 1 and a cooling box 2, the fan 1 is fixed on a support 3, the air inlet of the fan 1 is connected to the centrifugal dryer 4 through a pipeline, and the outlet of the fan 1 is connected through a curved The pipe 5 is connected to the cooling box 2, the right end of the cooling box 2 is provided with an air vent 6, the inside of the cooling box 2 is provided with a cooling coil 7, the outer wall of the cooling coil 7 is provided with cooling fins, the water inlet of the cooling coil 7 and The water outlets are respectively arranged on the outer wall of the heat dissipation box 2 , and the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com