Water-cooling long-life converter tapping hole

A technology for tapping holes and converters, applied in the direction of manufacturing converters, etc., can solve the problems of lost smelting time, etc., and achieve the effects of good water cooling effect, shortened replacement time, and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

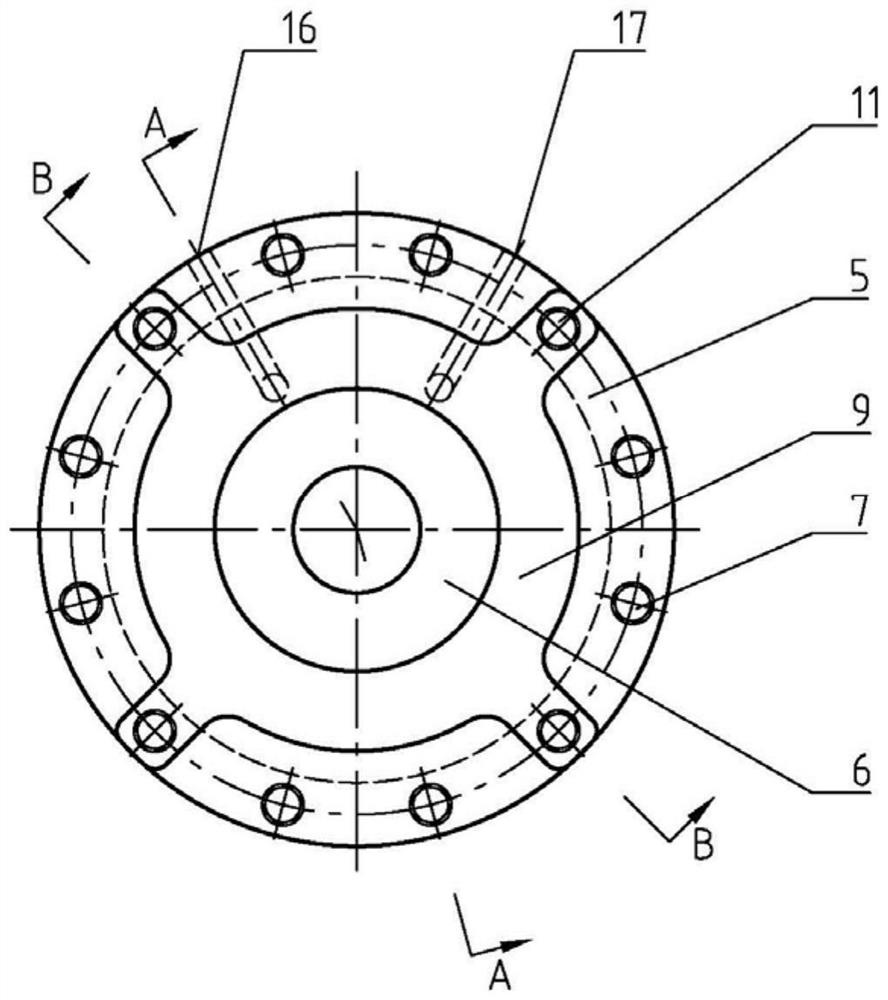

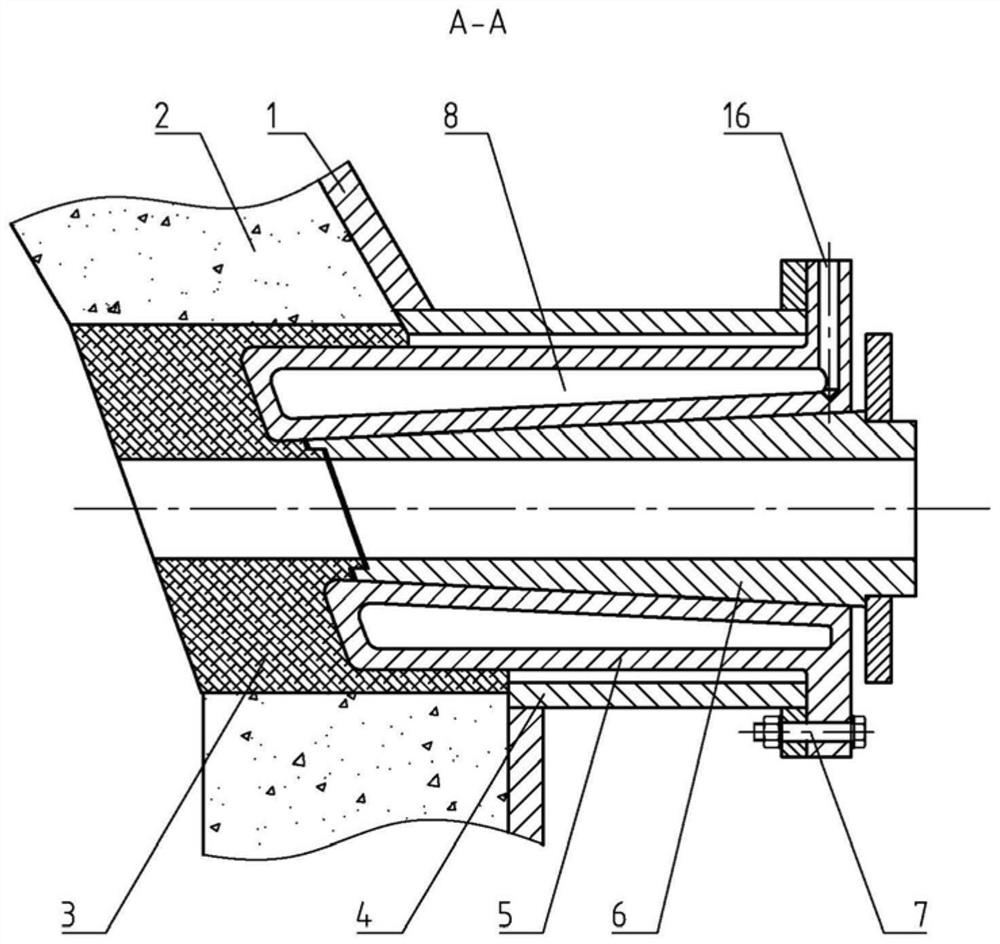

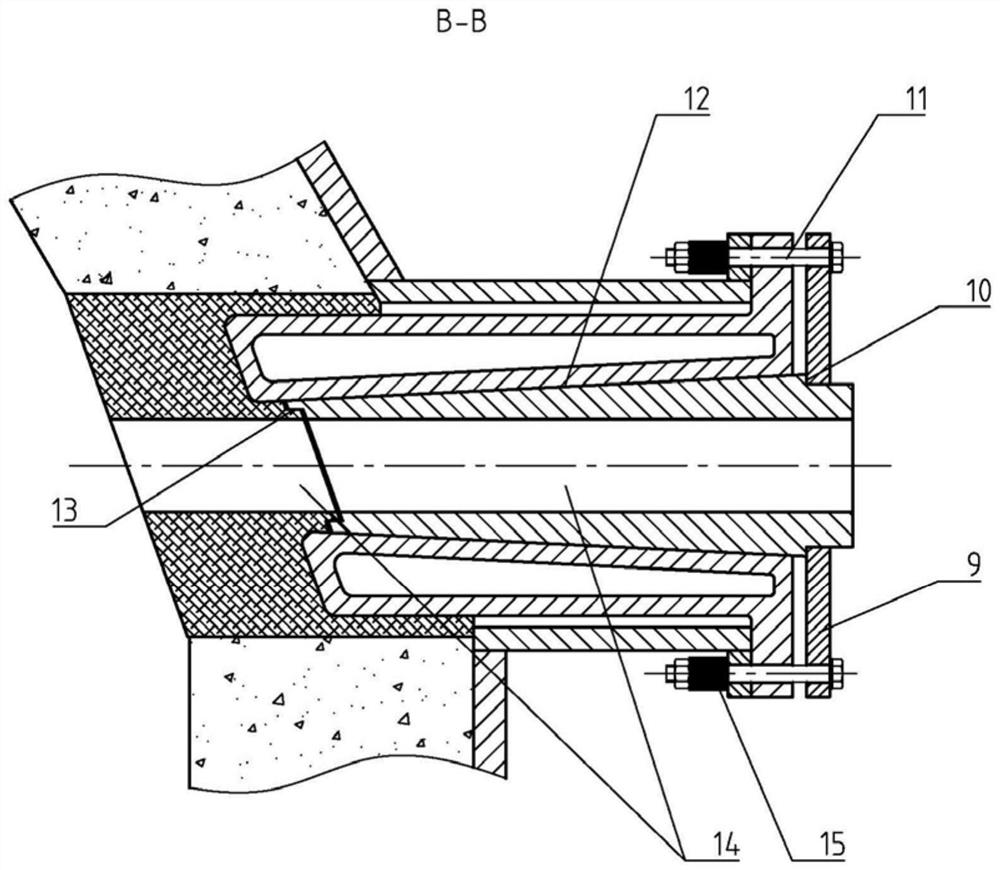

[0028] Embodiment 1, as attached figure 1 - attached image 3 Shown:

[0029] A taphole of a water-cooled long-life converter, including an outer jacket 4, a middle jacket 5, a core pipe 6, and a special-shaped seat brick 3. The outer jacket 4 is a steel cylindrical member, and one end matches the shape of the furnace shell 1 and is fixed to the furnace shell 1. Knotted together; the middle sleeve 5 is a cylindrical member made of metal, with a tapered hole inside, and the side wall is hollow to form a water chamber 8. One end of the middle sleeve 5 is a blind end, and the other end is provided with a water inlet that communicates with the water chamber 8 16 and water outlet 17; the core tube 6 is a metal tubular member with holes inside, and the outer surface is a conical shaft structure matching the taper hole of the middle sleeve 5; the special-shaped seat brick 3 is made of refractory material, and the inside is equipped with a 6 holes match the inner hole, and the stru...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap