Wear-resistant and anti-corrosion coating for corrugating machine

A technology for anti-corrosion coatings and corrugators, applied in the direction of anti-corrosion coatings, polyamide coatings, coatings, etc., can solve problems affecting product quality, surface coating wear, high operating frequency, etc., to achieve good sealing, excellent adhesion, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

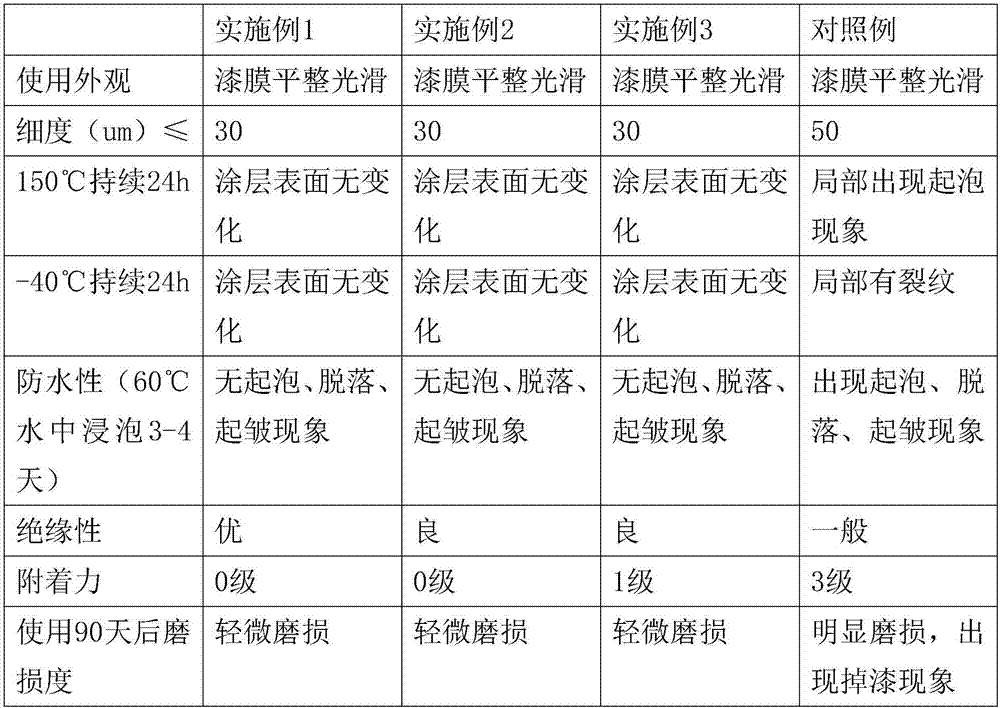

Embodiment 1

[0027] A wear-resistant and anti-corrosion coating for corrugating machines, prepared from the following components in parts by weight: 85 parts of polyvinylidene fluoride glue, 55 parts of resin, 10 parts of polylaurolactam, 12 parts of turpentine, 140 mesh 8 parts of mica powder, 8 parts of cellulose, 12 parts of sodium tripolyphosphate, 2 parts of salt lime, 3 parts of diatomaceous earth, 2 parts of melamine, 1 part of graphite powder, 2 parts of aluminum powder, 8 parts of beeswax, 3 parts of tapioca starch , 3 parts of curing agent, 8 parts of adhesion promoter, 5 parts of viscosity adjusting solvent, 3 parts of dispersing agent, 6 parts of coupling agent, 8 parts of biological antirust agent, and 3 parts of auxiliary agent.

[0028] Further, the resin is one of polyethylene resin, phenolic resin, epoxy resin, urea-formaldehyde resin, and polyamide resin.

[0029] Further, the curing agent is a polymeric polymer amine reagent.

[0030] Further, the adhesion promoter is a...

Embodiment 2

[0036] A wear-resistant and anti-corrosion coating for corrugating machines, prepared from the following components in parts by weight: 95 parts of polyvinylidene fluoride glue, 35 parts of resin, 10 parts of polylaurolactam, 11 parts of turpentine, 140 mesh 7 parts of mica powder, 7 parts of cellulose, 14 parts of sodium tripolyphosphate, 4 parts of salt lime, 4 parts of diatomaceous earth, 3 parts of melamine, 2 parts of graphite powder, 2 parts of aluminum powder, 6 parts of beeswax, and 2 parts of tapioca starch , 4 parts of curing agent, 6 parts of adhesion promoter, 3 parts of viscosity adjusting solvent, 4 parts of dispersant, 6 parts of coupling agent, 6 parts of biological antirust agent, and 3 parts of auxiliary agent.

[0037] Further, the resin is one of polyethylene resin, phenolic resin, epoxy resin, urea-formaldehyde resin, and polyamide resin.

[0038] Further, the curing agent is a polymeric polymer amine reagent.

[0039] Further, the adhesion promoter is a ...

Embodiment 3

[0045] A wear-resistant and anti-corrosion coating for corrugating machines, prepared from the following components in parts by weight: 66 parts of polyvinylidene fluoride glue, 45 parts of resin, 10 parts of polylaurolactam, 20 parts of turpentine, 140 mesh 8 parts of mica powder, 6 parts of cellulose, 12 parts of sodium tripolyphosphate, 3 parts of salt lime, 3 parts of diatomaceous earth, 2 parts of melamine, 2 parts of graphite powder, 1 part of aluminum powder, 8 parts of beeswax, and 5 parts of tapioca starch , 5 parts of curing agent, 10 parts of adhesion promoter, 6 parts of viscosity adjusting solvent, 3 parts of dispersant, 6 parts of coupling agent, 6 parts of biological antirust agent, and 4 parts of auxiliary agent.

[0046] Further, the resin is one of polyethylene resin, phenolic resin, epoxy resin, urea-formaldehyde resin, and polyamide resin.

[0047] Further, the curing agent is a polymeric polymer amine reagent.

[0048] Further, the adhesion promoter is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com