A method for controlling the grain growth process of nano-layered mgFe hydrotalcite

A grain growth, nano-layered technology, applied in nanotechnology, chemical instruments and methods, iron compounds, etc., can solve the problems of large crystal size of hydrotalcite and the inability to control the crystal size effectively, and achieves inhibition of aggregate growth, control The effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The control method of the growth process of MgFe hydrotalcite synthesized only by segmental crystallization method:

[0027] Prepare 0.4mol / L of Mg(NO 3 ) 2 and 0.1mol / L Fe(NO 3 ) 3 25mL each and mix well, where M 2 + :M 3+ (Mg:Fe)=4:1 (molar ratio), stir the above mixed metal nitrate solution evenly. Adopt the NaOH solution of deionized water preparation 3mol / L as precipitating agent, and add the NaOH solution of 3mol / L dropwise to above-mentioned mixed metal nitrate solution, precipitation occurs in the mixed solution, stop dripping when the pH value of the solution=10, Stir and mix evenly, transfer the mixed solution to a polytetrafluoroethylene-lined stainless steel reactor, crystallize at 180°C for 1 hour, and then continue to crystallize at 100°C for 24 hours. After crystallization, the product in the reactor was taken out, centrifuged and washed until the filtrate pH=7, and dried at 80°C for 24 hours to obtain a hydrotalcite product.

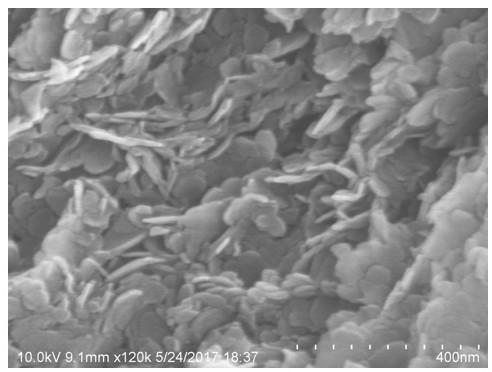

[0028] from figure...

Embodiment 2

[0030] The regulation method of the growth process of synthetic MgFe hydrotalcite only by adding organic steric hindrance agent:

[0031] A 3 mol / L NaOH solution was prepared with deionized water as a precipitant. At the same time, 0.4mol / L of Mg(NO 3 ) 2 and 0.1mol / L Fe(NO 3 ) 3 25mL each and mix well, where M 2+ :M 3+ (Mg:Fe)=4:1 (molar ratio). Stir the above mixed metal nitrate solution evenly, and add 3mol / L NaOH solution dropwise to it, precipitation appears in the mixed solution, stop the dropwise addition when the pH value of the solution=10, and then add triethanolamine with 5% of the total mass of the solution , stirred and mixed evenly, the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and crystallized at 180° C. for 24 hours. After crystallization, the product in the reactor was taken out, centrifuged and washed until the filtrate pH=7, and dried at 80°C for 24 hours to obtain a hydrotalcite product.

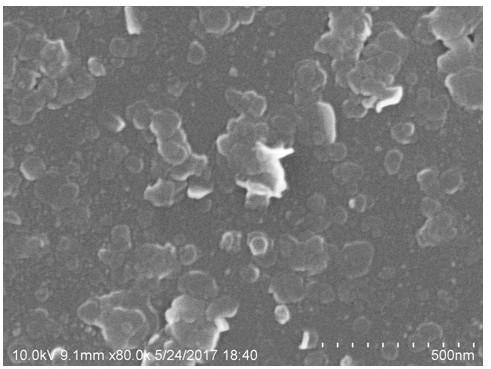

[0032] from...

Embodiment 3

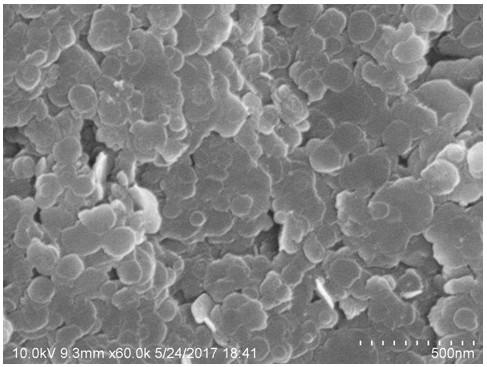

[0034] The control method of the nano-layered MgFe hydrotalcite grain growth process of the present invention:

[0035] Prepare 0.4mol / L of Mg(NO 3 ) 2 and 0.1mol / L Fe(NO 3 ) 3 25mL each and mix well, where M 2 + :M 3+ (Mg:Fe)=4:1 (molar ratio), stir the above mixed metal nitrate solution evenly. Adopt the NaOH solution of deionized water preparation 3mol / L as precipitating agent, dropwise add the NaOH solution of 3mol / L in the above-mentioned mixed metal nitrate solution, precipitation occurs in the mixed solution, stop dripping when the pH value of the solution=10, Then add triethanolamine with 5% of the total mass of the solution, stir and mix evenly, transfer the mixed solution to a polytetrafluoroethylene-lined stainless steel reactor, react at 180°C for 2h, and continue crystallization at 100°C for 24h . After the crystallization, the solid product in the reactor was taken out, centrifuged and washed until the filtrate pH=7, and dried at 80°C for 24 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com