Metal wire distortion machining equipment

A technology of processing equipment and metal wire, which is applied in the field of automatic processing equipment, can solve the problems of low processing efficiency and continuous production, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings and embodiments of the description, the specific embodiments of the present invention are described in further detail:

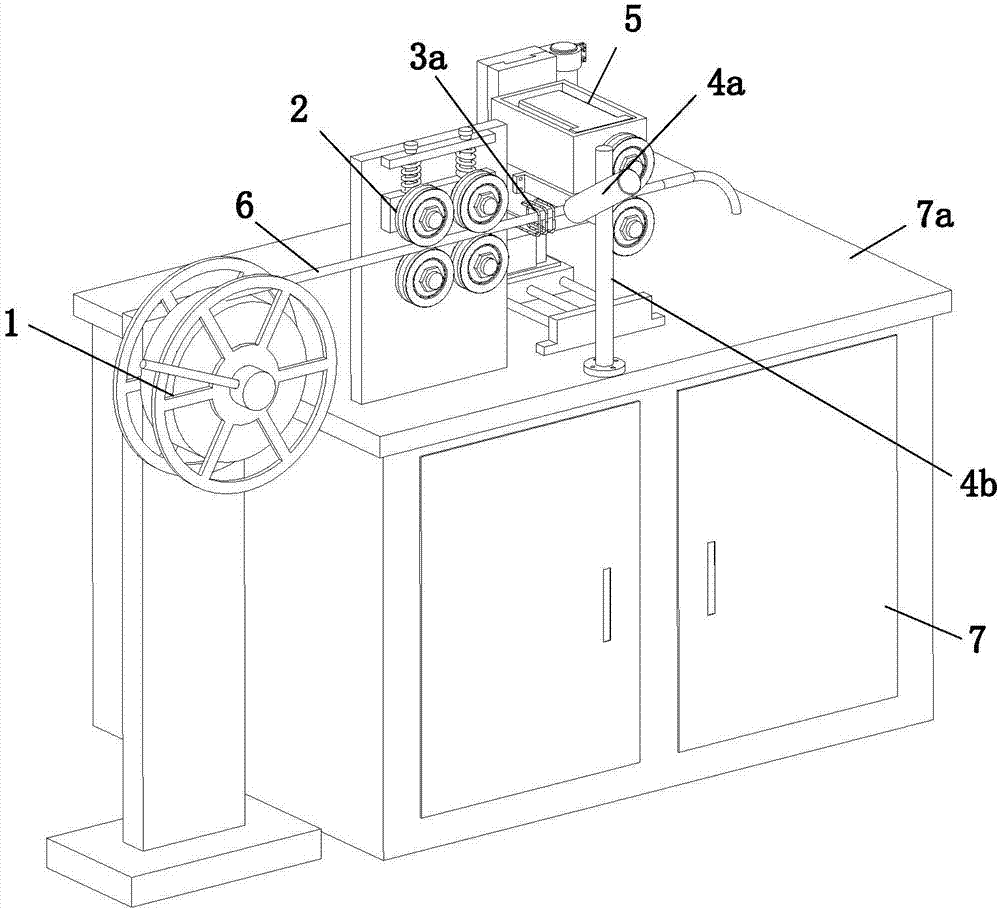

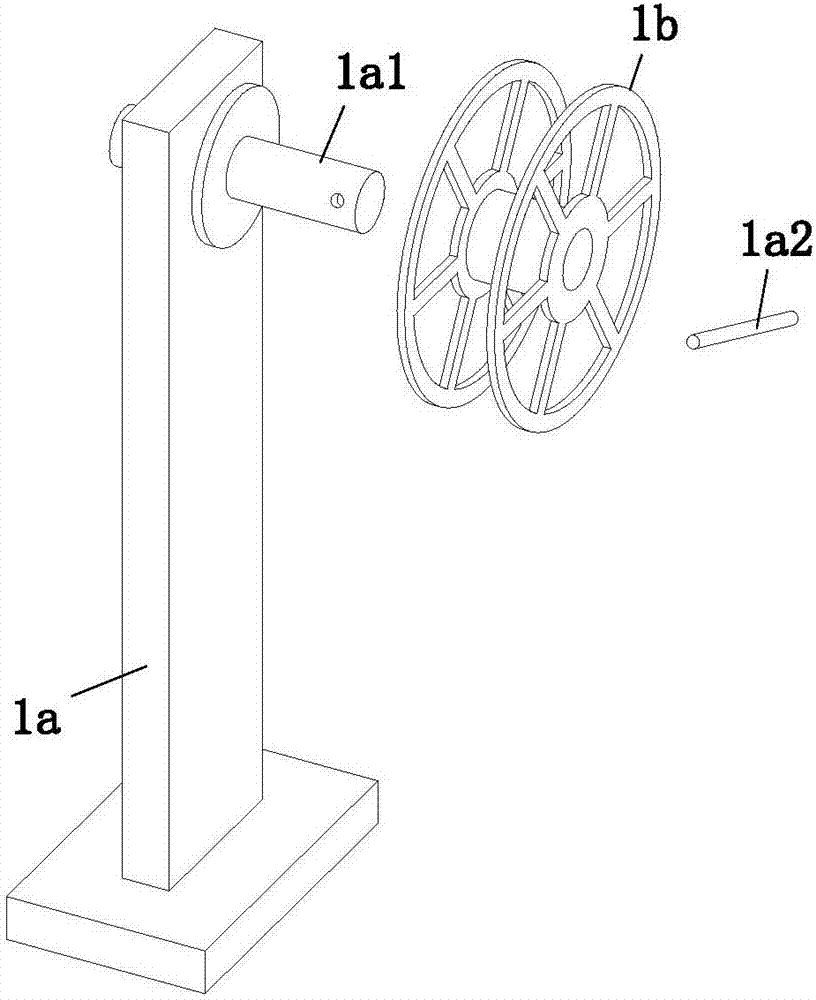

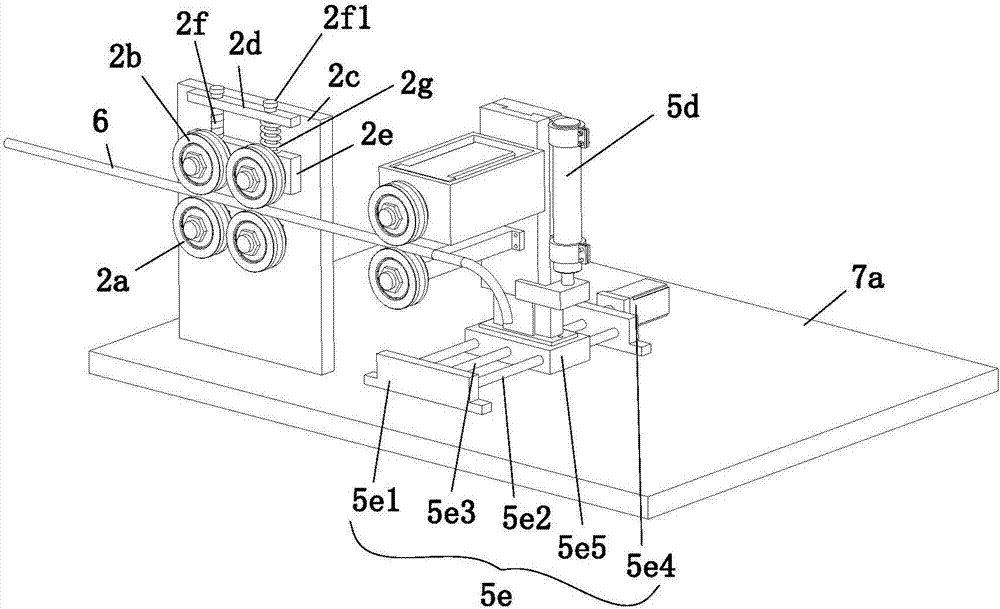

[0021] refer to Figure 1 to Figure 5 The shown equipment for twisting a metal wire includes a wire outlet mechanism 1, a clamping mechanism 2, a heating mechanism, a cooling mechanism and a twisting mechanism 5 arranged in sequence along one direction. 6 is pulled in its own direction, so that the wire 6 passes through the clamping mechanism 2, the heating mechanism and the cooling mechanism in turn. During the movement of the wire 6, the clamping mechanism 2 positions the wire 6, and the heating mechanism controls the outer surface of the wire 6. The circumferential surface is heated, the cooling mechanism cools the outer circumferential surface of the wire rod 6 , and finally the twisting mechanism 5 applies a twisting force to the heating portion of the wire rod 6 .

[0022] Specifically, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com