Method for preparing water-dispersing molecular imprinting fluorescent nanoparticles based on macromolecule self-assembling

A technology of molecular imprinting and fluorescent nanometers, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as complex preparation process, limited application in detection field, inability to identify target molecules, etc., to achieve The effect of high selectivity, widening the preparation and application environment, and fast adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

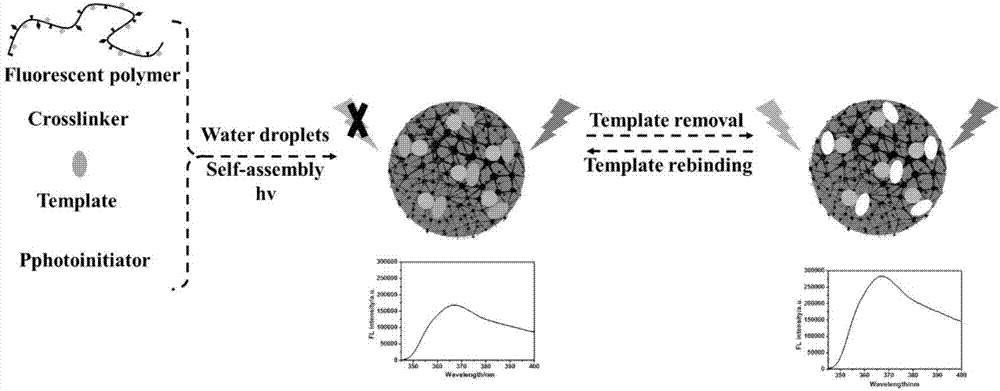

Method used

Image

Examples

Embodiment 1

[0022] The first step: Add monomer acrylic acid (0.3603g, 5mmol), vinylcarbazole (0.9663g, 5mmol), azobisisobutylcyanide (0.0328g, 2%mt%) into a 50ml round bottom flask, add solvent N,N-Dimethylformamide (DMF) 15mL, through N 2 After removing the oxygen in the solution for 20min, under stirring, the temperature was kept at 80°C and reacted in an oil bath for 24h. The monomer ethylene glycol methacrylate (0.711g, 5mmol), triphenylphosphine (0.0262g, 0.1mmol) and hydroquinone (0.0028g, 0.025mmol) were dissolved in 5mL of DMF, and were added dropwise to the above polymer solution through a constant pressure dropping funnel. Under stirring, the temperature was maintained at 95°C in oil React in the bath for 12 hours, precipitate with petroleum ether three times, and dry in a vacuum oven at 40°C overnight to obtain a photosensitive fluorescent polymer;

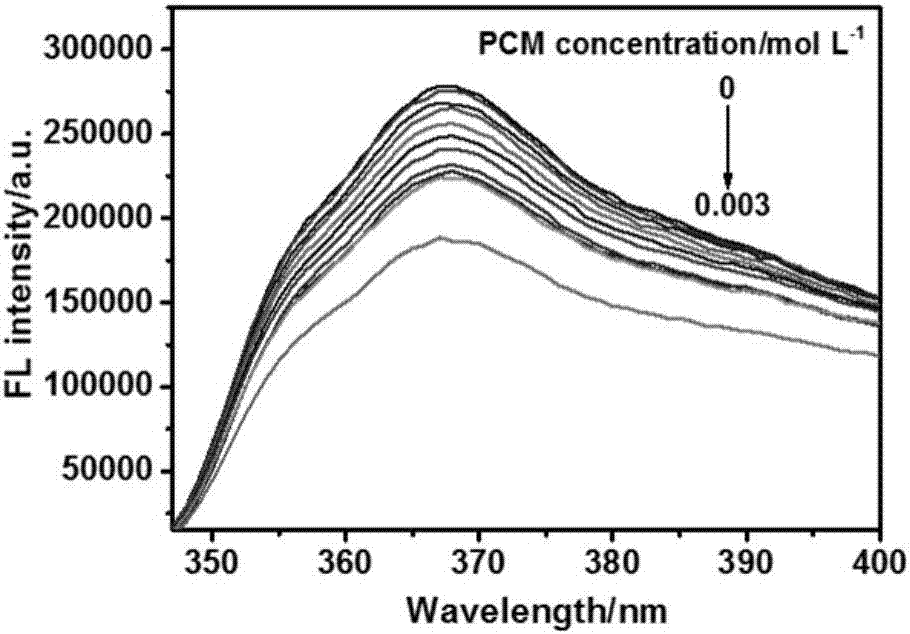

[0023] Step 2: Dissolve 10 mg of the above polymer in DMF, a good solvent, and add 10 μL of paracetamol in DMF (2 mg mL -1 ), ...

Embodiment 2

[0026] The first step: Add monomer acrylic acid (0.7206g, 10mmol), vinyl carbazole (0.9663g, 5mmol), azobisisobutylcyanide (0.0328g, 2%mt%) into a 50ml round bottom flask, add solvent N,N-Dimethylformamide (DMF) 15mL, through N 2 After removing the oxygen in the solution for 20min, under stirring, the temperature was kept at 90°C and reacted in an oil bath for 24h. The monomer ethylene glycol methacrylate (1.422g, 10mmol), triphenylphosphine (0.0262g, 0.1mmol) and hydroquinone (0.0028g, 0.025mmol) were dissolved in 5mL of DMF, and were added dropwise to the above polymer solution through a constant pressure dropping funnel, and the temperature was kept at 95°C under stirring. React in the bath for 12 hours, precipitate with petroleum ether three times, and dry in a vacuum oven at 40°C overnight to obtain a photosensitive fluorescent polymer;

[0027] Step 2: Dissolve 10 mg of the above polymer in DMF, a good solvent, and add 10 μL of paracetamol in DMF (2 mg mL -1 ), 5 μL cro...

Embodiment 3

[0030] The first step: monomer methacrylic acid (0.4403g, 5mmol), vinyl carbazole (1.9326g, 10mmol), azobisisobutylcyanide (0.0328g, 2%mt%) were added in a 50ml round bottom flask, Add solvent N,N-dimethylformamide (DMF) 15mL, pass N 2 After removing the oxygen in the solution for 20min, under stirring, the temperature was kept at 80°C and reacted in an oil bath for 24h. The monomer ethylene glycol methacrylate (0.711g, 5mmol), triphenylphosphine (0.0262g, 0.1mmol) and hydroquinone (0.0028g, 0.025mmol) were dissolved in 5mL DMF, and were added dropwise to the above polymer solution through a constant pressure dropping funnel. React in the bath for 12 hours, precipitate with petroleum ether three times, and dry in a vacuum oven at 40°C overnight to obtain a photosensitive fluorescent polymer;

[0031] Step 2: Dissolve 10 mg of the above polymer in DMF, a good solvent, and add 10 μL of paracetamol in DMF (2 mg mL -1 ), 10 μL crosslinker divinylbenzene and 20 μL photoinitiator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com