Device and method for testing high-temperature thermal radiation coefficient of ablation heat-resistant material

A technology of thermal radiation coefficient and heat-resistant materials, which is applied in the directions of measuring devices, analyzing materials, and material analysis through optical means, which can solve the problem of huge differences in thermal radiation characteristic parameters, interference, and the inability to achieve high-temperature heat radiation of ablation heat-resistant materials coefficient test etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, content, and beneficial effects of the present invention clearer, the implementation of the present invention will be specifically described below in conjunction with the accompanying drawings and examples.

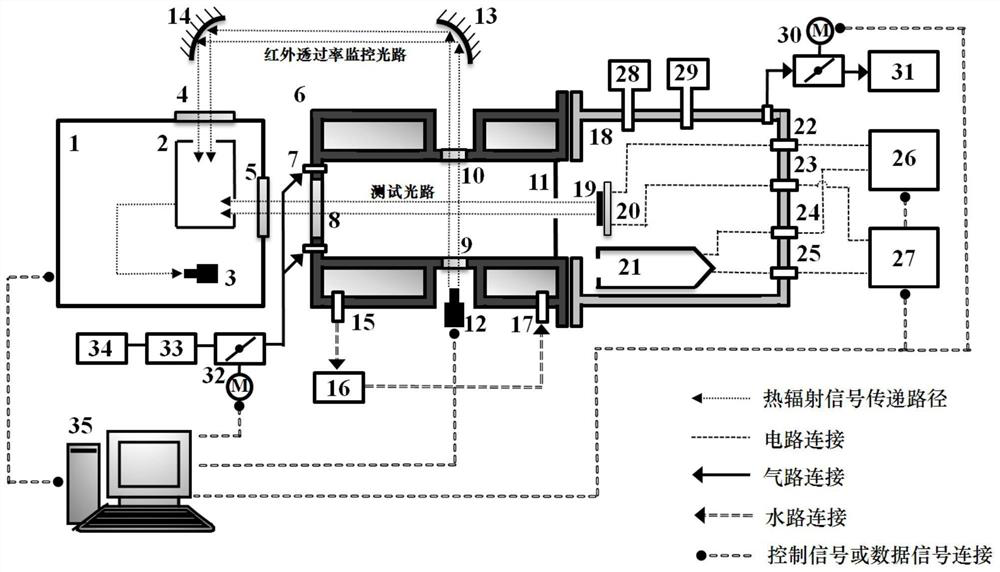

[0035] as attached figure 1 As shown, the present invention proposes a high-temperature heat radiation coefficient testing device for ablation heat-resistant materials, including a Fourier transform infrared spectrometer 1, a sample and blackbody heating furnace 18, a water-cooled optical tip 6, and the airflow intensity can be real-time online Control the inert atmosphere purging system and the real-time monitoring system for the infrared transmittance of the test optical path.

[0036] The Fourier transform infrared spectrometer 1 includes a beam splitter 2, an infrared signal detector 3, high infrared transmittance windows B1 5, high infrared transmittance windows B2 4, and is connected with a computer 35. For high infrared transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com