Manufacturing method for upconversion luminescent material

A technology of luminescent materials and manufacturing methods, which is applied in the direction of luminescent materials, chemical instruments and methods, metal material coating technology, etc., can solve the problems of insufficient uniformity and dispersion of product particles, high synthesis costs, etc., and achieve improved photoelectric conversion efficiency, Low cost, avoid the effect of deep processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

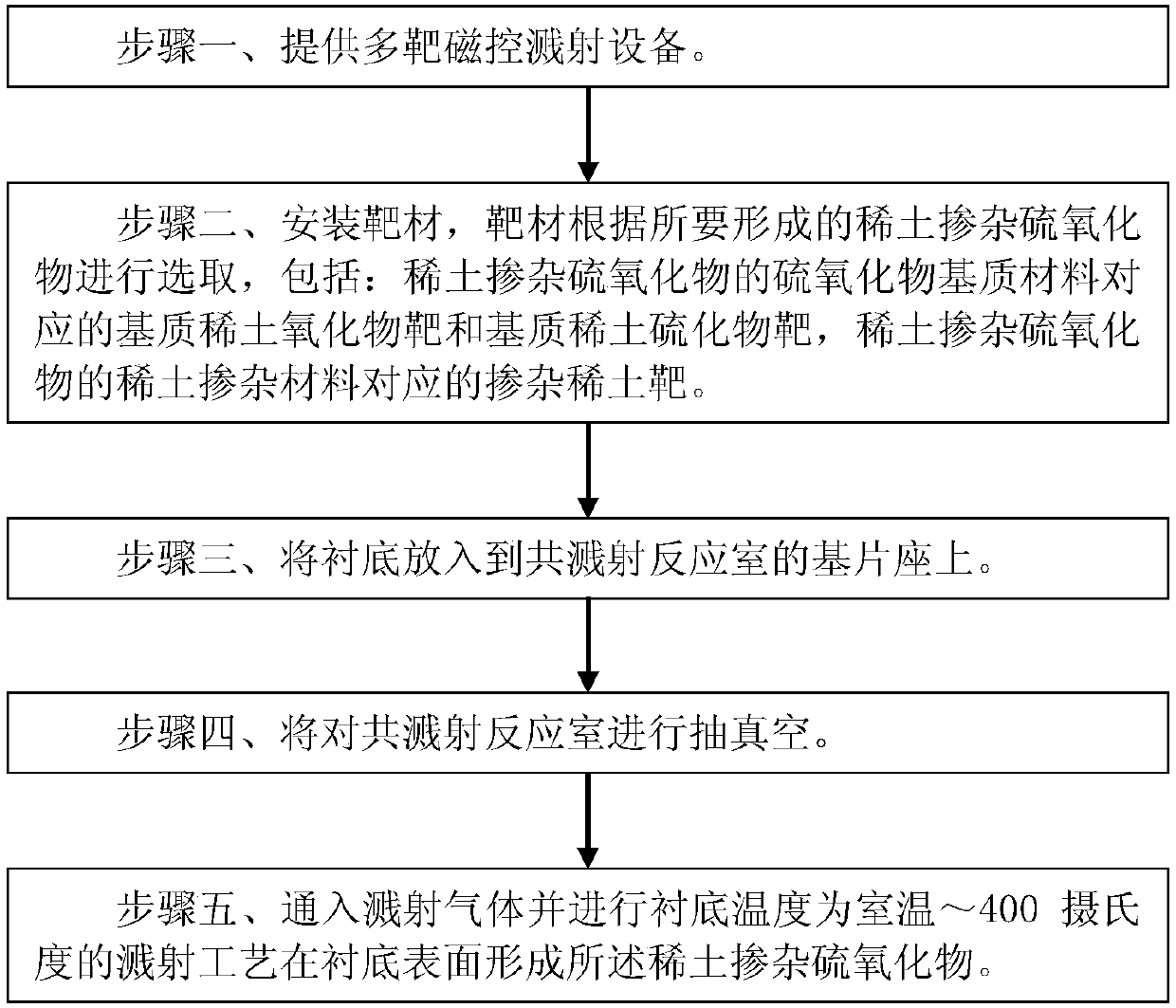

[0027] like figure 1 As shown, it is a flow chart of the method of the embodiment of the present invention. In the manufacturing method of the up-conversion luminescent material in the embodiment of the present invention, the up-conversion luminescent material is composed of rare earth-doped sulfur oxides formed by the following steps:

[0028] Step 1, providing multi-target magnetron sputtering equipment.

[0029] Step 2, installing a plurality of targets in the co-sputtering reaction chamber of the multi-target magnetron sputtering equipment, the targets are selected according to the rare earth doped sulfur oxide to be formed, including:

[0030] The rare earth doped sulfur oxide host material corresponds to a host rare earth oxide target and a host rare earth sulfide target, and the rare earth doped sulfur oxide rare earth doped material corresponds to a doped rare earth target.

[0031] In the embodiment of the present invention, the oxysulfide host material of the rare e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com