Halogen-free flame-retardant resin and preparation method thereof

A flame retardant resin and epoxy resin technology, applied in the field of halogen-free flame retardant resin and its preparation, can solve the problems of precipitation of flame retardants, poor mechanical properties of products, easy water absorption on the surface, etc. Good barrier properties, mechanical properties and anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

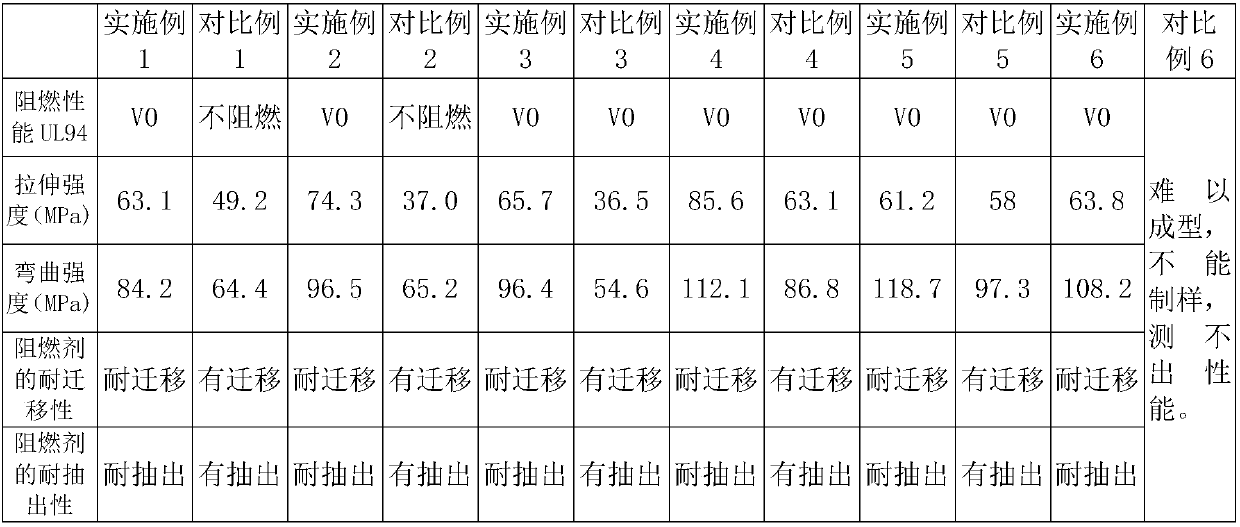

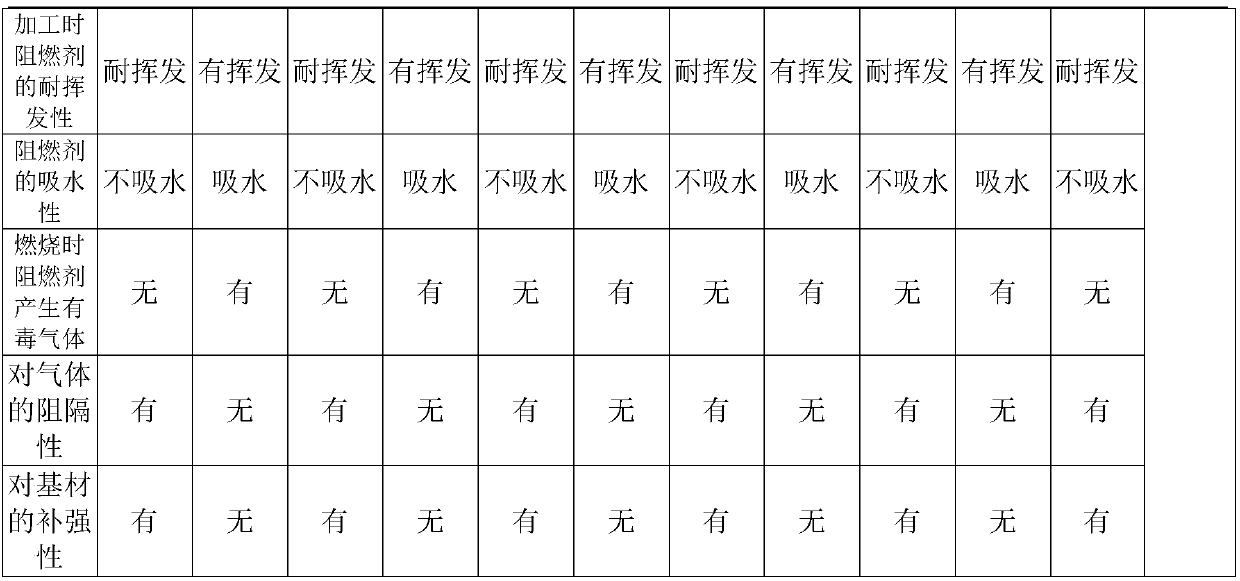

Examples

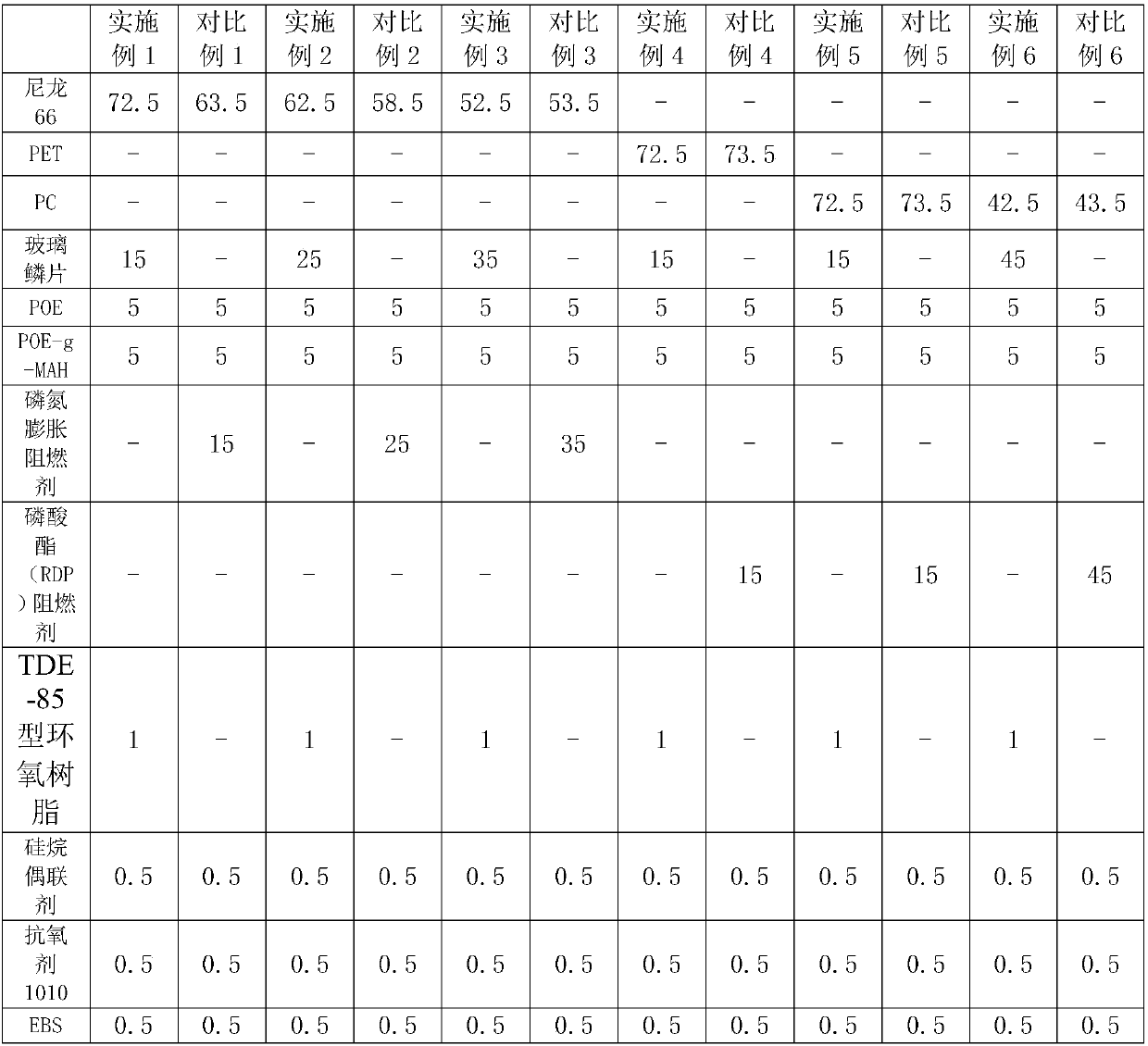

Embodiment 1

[0032] A kind of halogen-free flame-retardant resin, the weight percentage content of nylon 66 is 72.5%, the weight percentage content of glass flakes is 15%, the weight percentage content of POE toughening agent is 5%, and the weight percentage content of POE-g-MAH compatibilizer is The content is 5%, the weight percentage content of epoxy resin TDE-85 is 1%, the weight percentage content of coupling agent is 0.5%, the weight percentage content of antioxidant is 0.5%, and the weight percentage content of lubricant EBS is 0.5% %.

[0033] First dilute the coupling agent and epoxy resin with solvent acetone, the amount of solvent is 10 times of the amount of coupling agent and epoxy resin. Then the glass flakes and the diluted mixed solution are stirred evenly in a high-speed mixer to allow the solvent to evaporate. Then, the compatibilizer, the toughening agent, and the treated glass flakes are uniformly mixed in a double-roll mill, and then formed into granules for later use...

Embodiment 2

[0036] A kind of halogen-free flame-retardant resin, the weight percentage content of nylon 66 is 62.5%, the weight percentage content of glass flakes is 25%, the weight percentage content of POE toughening agent is 5%, the weight percentage content of POE-g-MAH compatibilizer The content is 5%, the weight percentage content of epoxy resin TDE-85 is 1%, the weight percentage content of coupling agent is 0.5%, the weight percentage content of antioxidant is 0.5%, and the weight percentage content of lubricant EBS is 0.5% %.

[0037] First dilute the coupling agent and epoxy resin with solvent acetone, the amount of solvent is 10 times of the amount of coupling agent and epoxy resin. Then the glass flakes and the diluted mixed solution are stirred evenly in a high-speed mixer to allow the solvent to evaporate. Then, the compatibilizer, the toughening agent, and the treated glass flakes are uniformly mixed in a double-roll mill, and then formed into granules for later use. The ...

Embodiment 3

[0040] A kind of halogen-free flame-retardant resin, the weight percentage content of nylon 66 is 52.5%, the weight percentage content of glass flakes is 35%, the weight percentage content of POE toughening agent is 5%, the weight percentage content of POE-g-MAH compatibilizer The content is 5%, the weight percentage content of epoxy resin TDE-85 is 1%, the weight percentage content of coupling agent is 0.5%, the weight percentage content of antioxidant is 0.5%, and the weight percentage content of lubricant EBS is 0.5% %.

[0041] First dilute the coupling agent and epoxy resin with solvent acetone, the amount of solvent is 10 times of the amount of coupling agent and epoxy resin. Then the glass flakes and the diluted mixed solution are stirred evenly in a high-speed mixer to allow the solvent to evaporate. Then, the compatibilizer, the toughening agent, and the treated glass flakes are uniformly mixed in a double-roll mill, and then formed into granules for later use. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com