Shaping chain tooth with amplified and changed tooth body, and sliding wedge and zipper matched with shaping chain tooth

A technology of sprocket teeth and tooth body, applied in the field of sliding wedge, can solve the problems of reduced meshing function, undisclosed, deformation, etc., and achieve the effects of preventing strain, strengthening structural strength, and being easy to disengage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

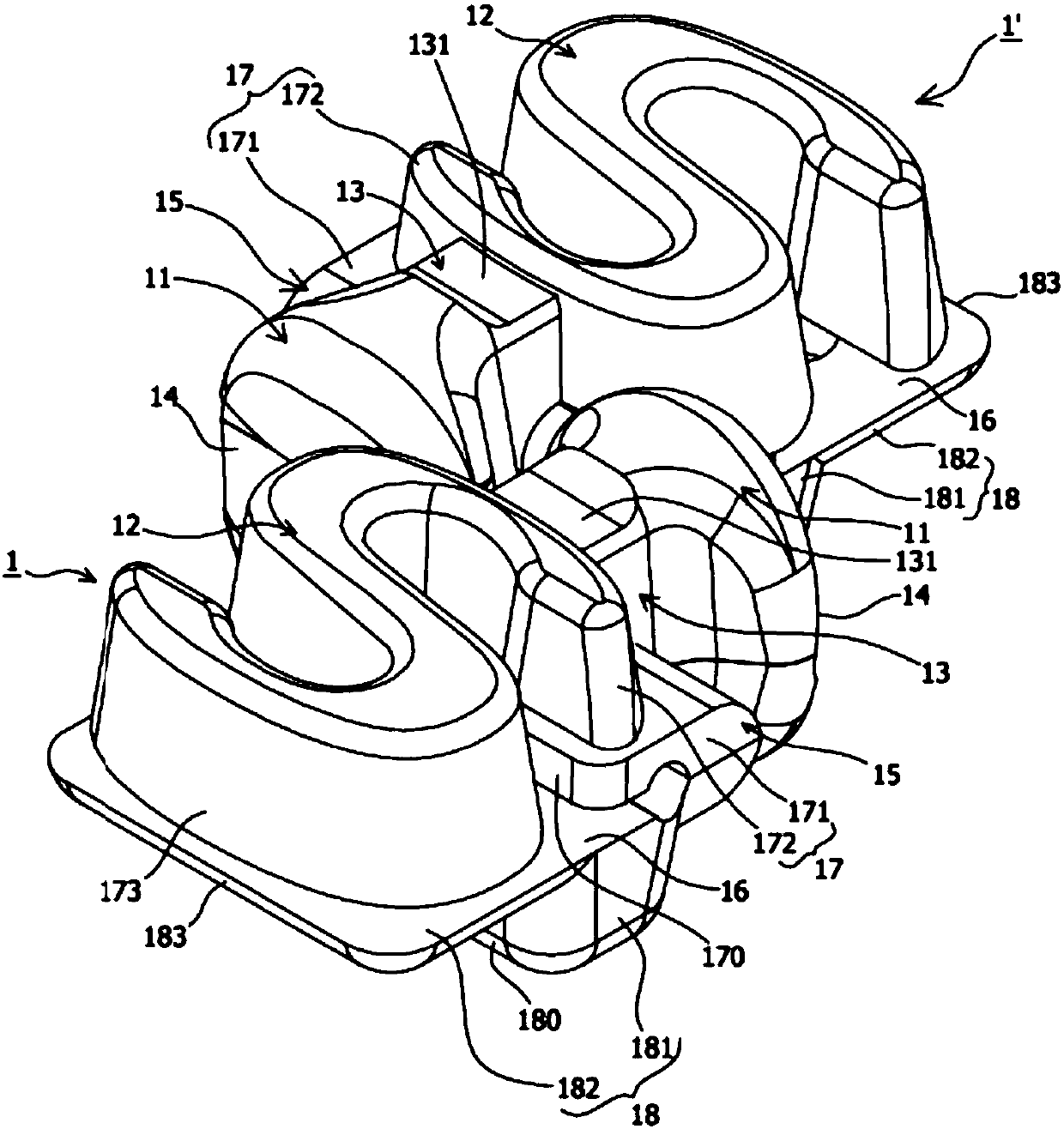

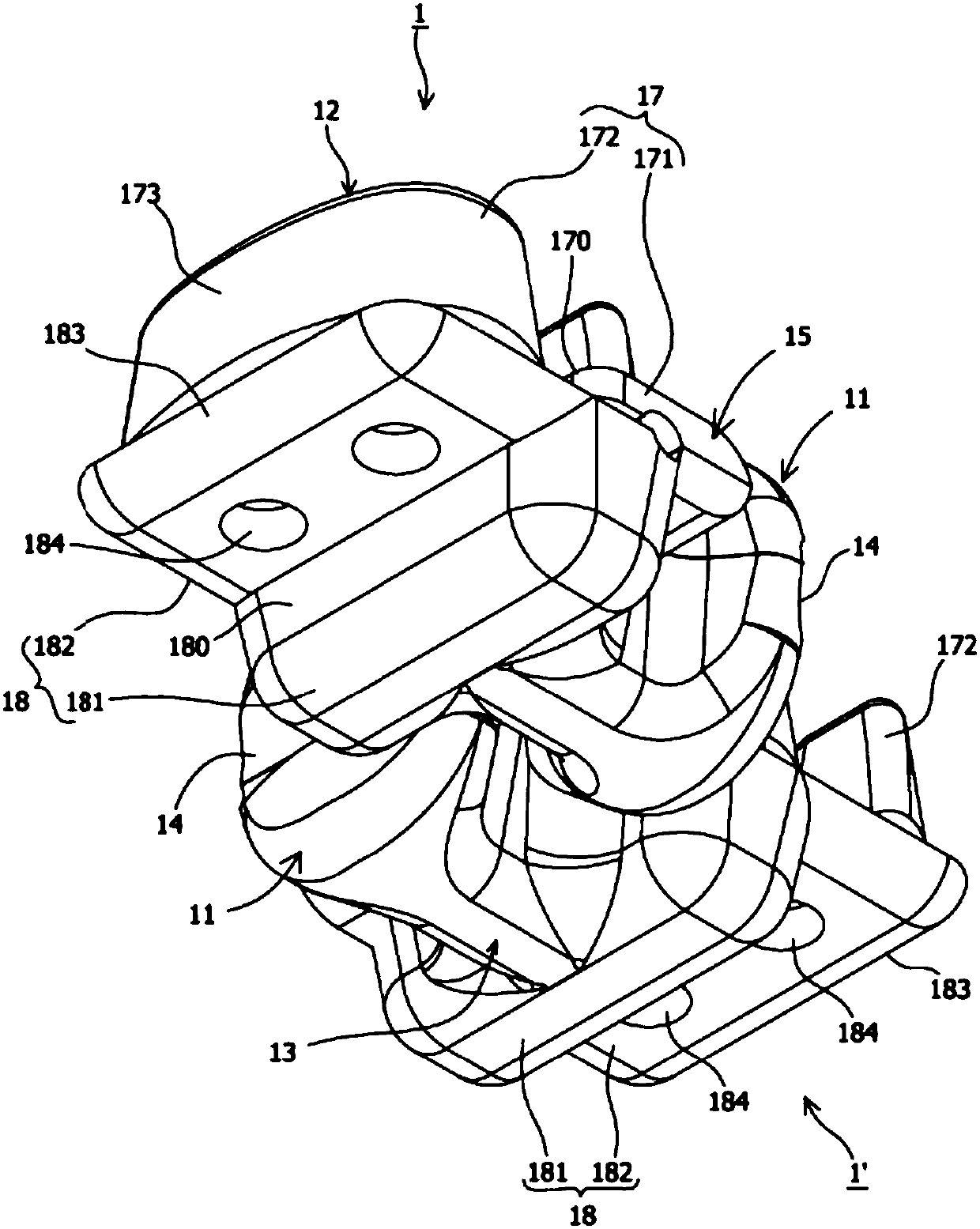

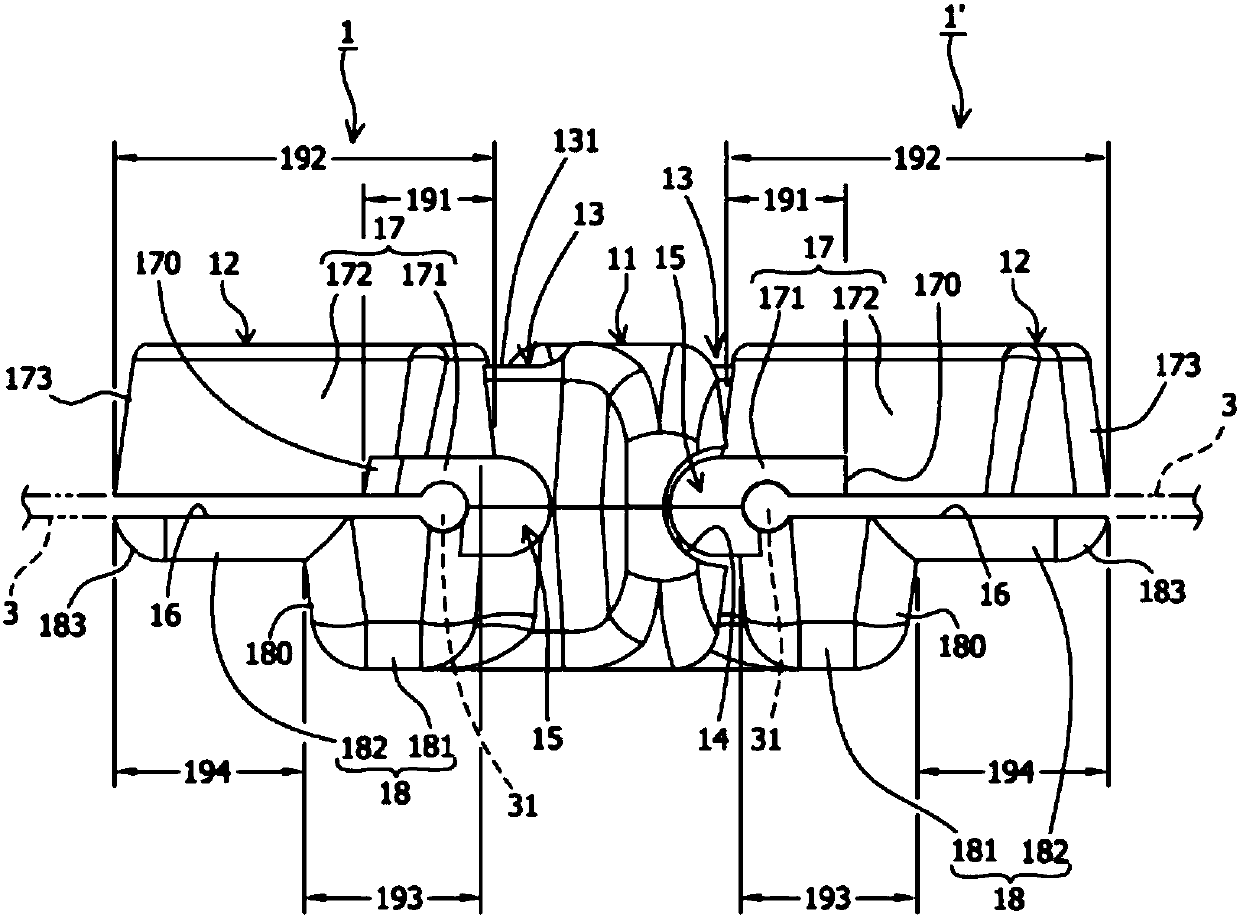

[0043] According to the embodiment shown in the drawings, the detailed description is as follows:

[0044] Such as Figure 1 to Figure 2 As shown in the figure, a pair of shaped chain teeth 1, 1' are revealed in the drawing, and they are staggered left and right. One end is a tooth body portion 12 correspondingly connected with the meshing portion 11, a neck 13 with a narrow diameter is formed between the meshing portion 11 and the tooth body portion 12, and the outer top edge of the meshing portion 11 has a concave tooth groove 14 , and there are block-shaped shoulders 15 on the left and right sides of the connection between the tooth body 12 and the neck 13, and the shoulders 15 can be embedded in the meshing grooves of the staggered and opposite formed chain teeth 1' or 1 14 to achieve the fitting function, and the tooth body portion 12 has a notch towards the tail end, and can be fixed and straddle the inner edge of the webbing 3 and the clamping groove 16 of the core 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com