Light source capable of adjusting color temperatures and color rendering indexes

An adjustable color temperature technology, applied in the direction of light source, light source fixing, lighting and heating equipment, etc., can solve the problems of increasing LED gold wire breakage and open circuit, inconsistent power density in different areas, thermal imbalance and other problems, so as to achieve unsatisfactory reliability of the whole lamp. Damaged, no risk of thermal mismatch, long life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

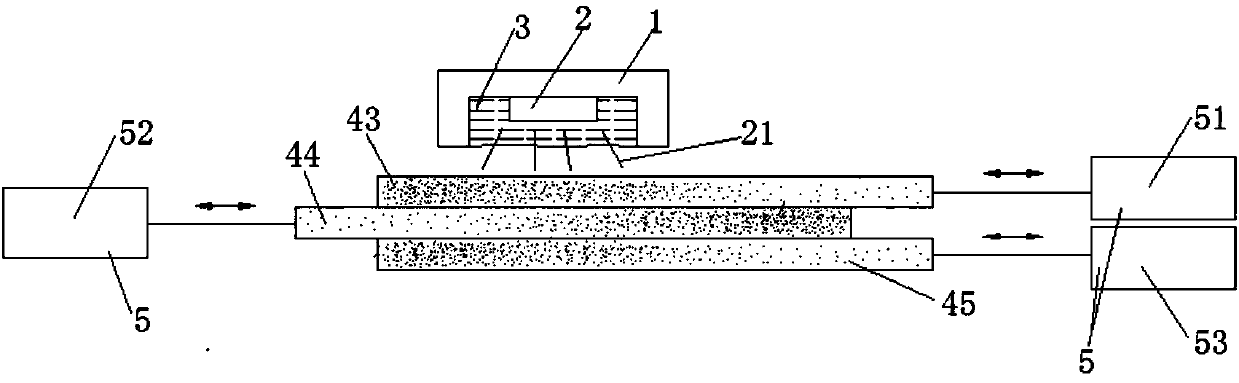

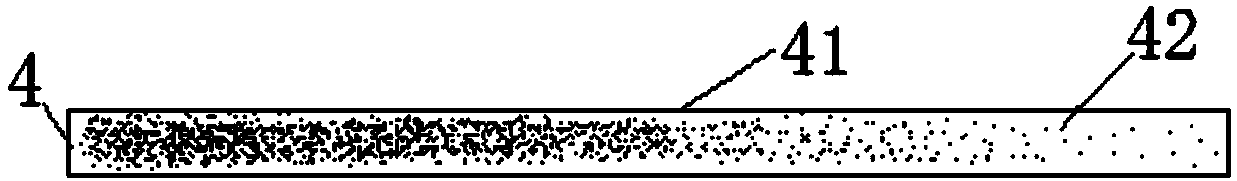

[0035] The invention discloses a light source with adjustable color temperature and display index, such as Figure 1-4 As shown, it includes a substrate 1, a blue light emitting diode 2, a variety of fluorescent diaphragms 4, and a plurality of control modules 5; the blue light emitting diode 2 is electrically connected to the substrate 1, and the fluorescent diaphragm 4 is installed on the light output path of the blue light emitting diode 2 21, each fluorescent membrane 4 is connected to a control module 5 correspondingly.

[0036]Specifically, the connection between the blue light emitting diode 2 chip and the substrate 1 can be through front-chip gold wire bonding or flip-chip eutectic welding.

[0037] In this embodiment, the control module 5 includes a control core and an action actuator; the control core receives an externally input color temperature control signal, and calculates and outputs a pulse waveform for adjusting the position of the fluorescent diaphragm 4 thr...

Embodiment 2

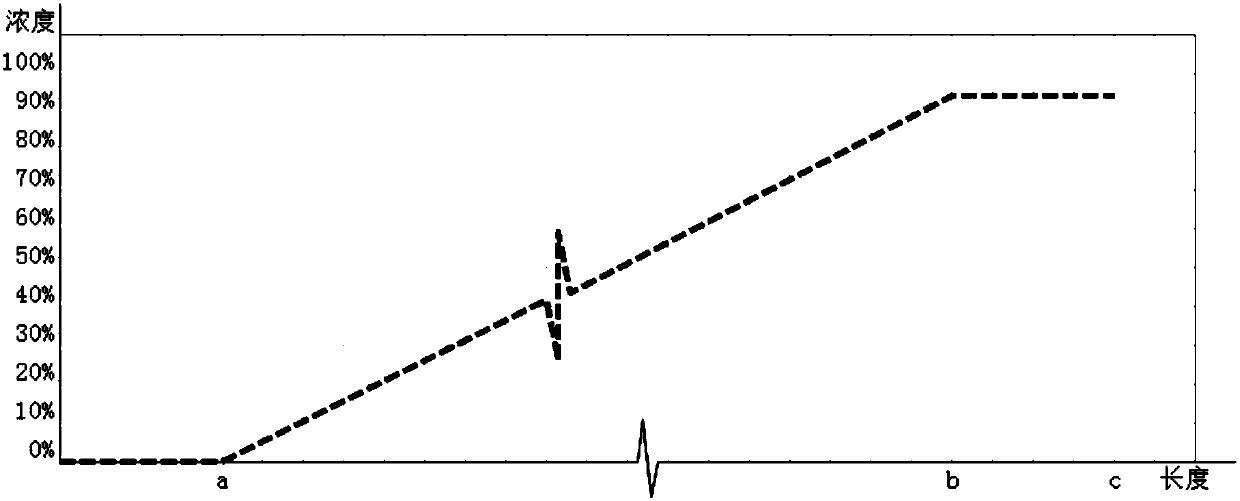

[0049] The present invention provides yet another light source with adjustable color temperature and color display, such as Figure 5 , 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that the red fluorescent diaphragm 43, the green fluorescent diaphragm 44, and the yellow fluorescent diaphragm 45 of this embodiment are all circular, and they pass through the rotating shaft Placed concentrically; the distribution of red fluorescent conversion material 421, green fluorescent conversion material 422, and yellow fluorescent conversion material 423 on the corresponding circular red fluorescent membrane 43, green fluorescent membrane 44, and yellow fluorescent membrane 45 is: along the circular In the circumferential direction of the circle, the concentration is distributed from high to low, along the radial direction of the circle, the concentration is equal, and the highest concentration and the lowest concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com