New composite material of polyvinyl chloride and nitrile butadiene rubber

A technology of nitrile rubber and polyvinyl chloride, which is applied in the field of polymer material modification, can solve problems such as poor low temperature resistance, poor insulation performance, and poor ozone resistance, so as to improve chemical resistance and oil resistance, and change low temperature resistance properties, effects of changing susceptibility to aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

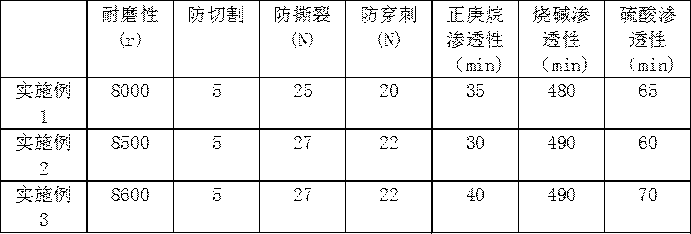

Examples

Embodiment 1

[0019] A new composite material of polyvinyl chloride and nitrile rubber. After the modification process of nitrile rubber and the composite process of polyvinyl chloride and nitrile rubber, the preparation of the new composite material of polyvinyl chloride and nitrile rubber is completed. Specifically Proceed as follows:

[0020] (1) Modification process of nitrile rubber: mix nitrile rubber with flexible plasticizer, the flexible plasticizer is citric acid plasticizer and polyester plasticizer, nitrile rubber, citric acid plasticizer and The mixing mass ratio of the polyester plasticizer is 2:1:1, heated to 45 degrees centigrade with water isolation, then high-speed stirring, the high-speed stirring speed is 800r / min, and the stirring time is 1 hour, after stirring evenly, let it stand for 22 hours, A modified nitrile rubber is obtained.

[0021] (2) Composite process of polyvinyl chloride and nitrile rubber: mix modified nitrile rubber, flexible plasticizer, stabilizer, r...

Embodiment 2

[0023] A new composite material of polyvinyl chloride and nitrile rubber. After the modification process of nitrile rubber and the composite process of polyvinyl chloride and nitrile rubber, the preparation of the new composite material of polyvinyl chloride and nitrile rubber is completed. Specifically Proceed as follows:

[0024] (1) Modification process of nitrile rubber: mix nitrile rubber with flexible plasticizer, the flexible plasticizer is citric acid plasticizer and polyester plasticizer, nitrile rubber, citric acid plasticizer and The mixing mass ratio of the polyester plasticizer is 2:1:1, heated to 55 degrees centigrade in water isolation, then high-speed stirring, the high-speed stirring speed is 1000r / min, and the stirring time is 1.5 hours, and it is left to stand for 26 hours after stirring evenly. A modified nitrile rubber is obtained.

[0025] (2) Composite process of polyvinyl chloride and nitrile rubber: mix modified nitrile rubber, flexible plasticizer, s...

Embodiment 3

[0027] A new composite material of polyvinyl chloride and nitrile rubber. After the modification process of nitrile rubber and the composite process of polyvinyl chloride and nitrile rubber, the preparation of the new composite material of polyvinyl chloride and nitrile rubber is completed. Specifically Proceed as follows:

[0028] (1) Modification process of nitrile rubber: mix nitrile rubber with flexible plasticizer, the flexible plasticizer is citric acid plasticizer and polyester plasticizer, nitrile rubber, citric acid plasticizer and The mixing mass ratio of the polyester plasticizer is 2:1:1, heated to 50 degrees Celsius in water, then high-speed stirring, the high-speed stirring speed is 900r / min, and the stirring time is 1.2 hours. After stirring evenly, let it stand for 24 hours. A modified nitrile rubber is obtained.

[0029] (2) Composite process of polyvinyl chloride and nitrile rubber: mix modified nitrile rubber, flexible plasticizer, stabilizer, rheological a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com