Waste water zero discharge acrylic acid refining device and process

An acrylic acid, zero-discharge technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem of not fundamentally achieving zero-discharge of wastewater and long-term cycle, and achieve the goal of saving consumption, reducing production costs and reducing losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

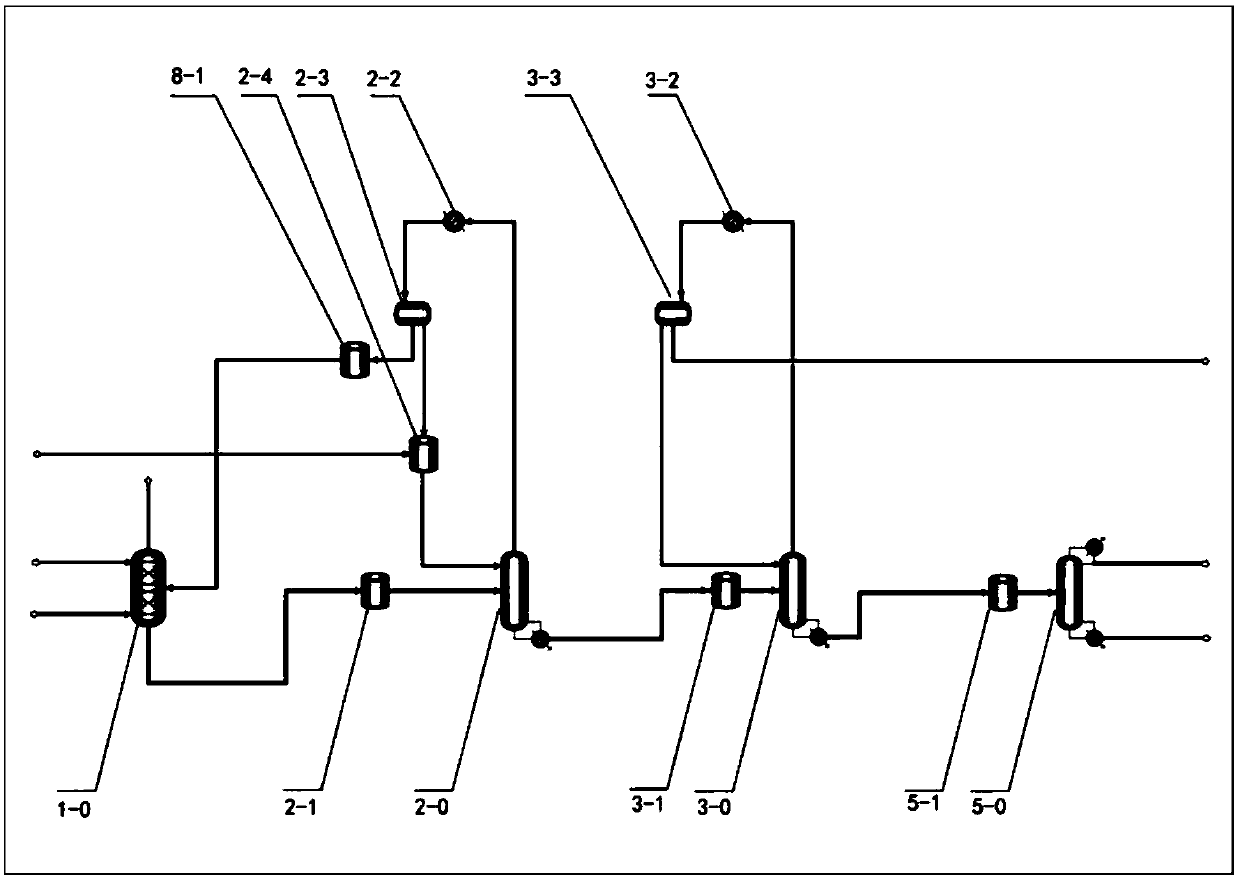

[0035] Such as figure 1 As shown, a kind of acrylic acid refining device with zero discharge of waste water, said device includes absorption tower 1-0, dehydration tower 2-0, deacetic acid tower 3-0, weight removal tower 5-0, first circulation system and second Circulation system; the bottom outlet of the absorption tower 1-0 is connected to the inlet of the dehydration tower 2-0 through the first storage tank 2-1; the top outlet of the dehydration tower 2-0 is connected to the first circulation The system is connected; the bottom outlet of the dehydration tower 2-0 is connected with the inlet of the deacetic acid tower 3-0 through the second storage tank 3-1; the top outlet of the dehydration tower 3-0 is connected with the The second circulation system is connected; the bottom outlet of the deacetic acid tower 3-0 is connected with the weight removal tower 5-0 through the third storage tank 4-1.

[0036] The first circulation system includes a first condenser 2-2, a first s...

Embodiment 2

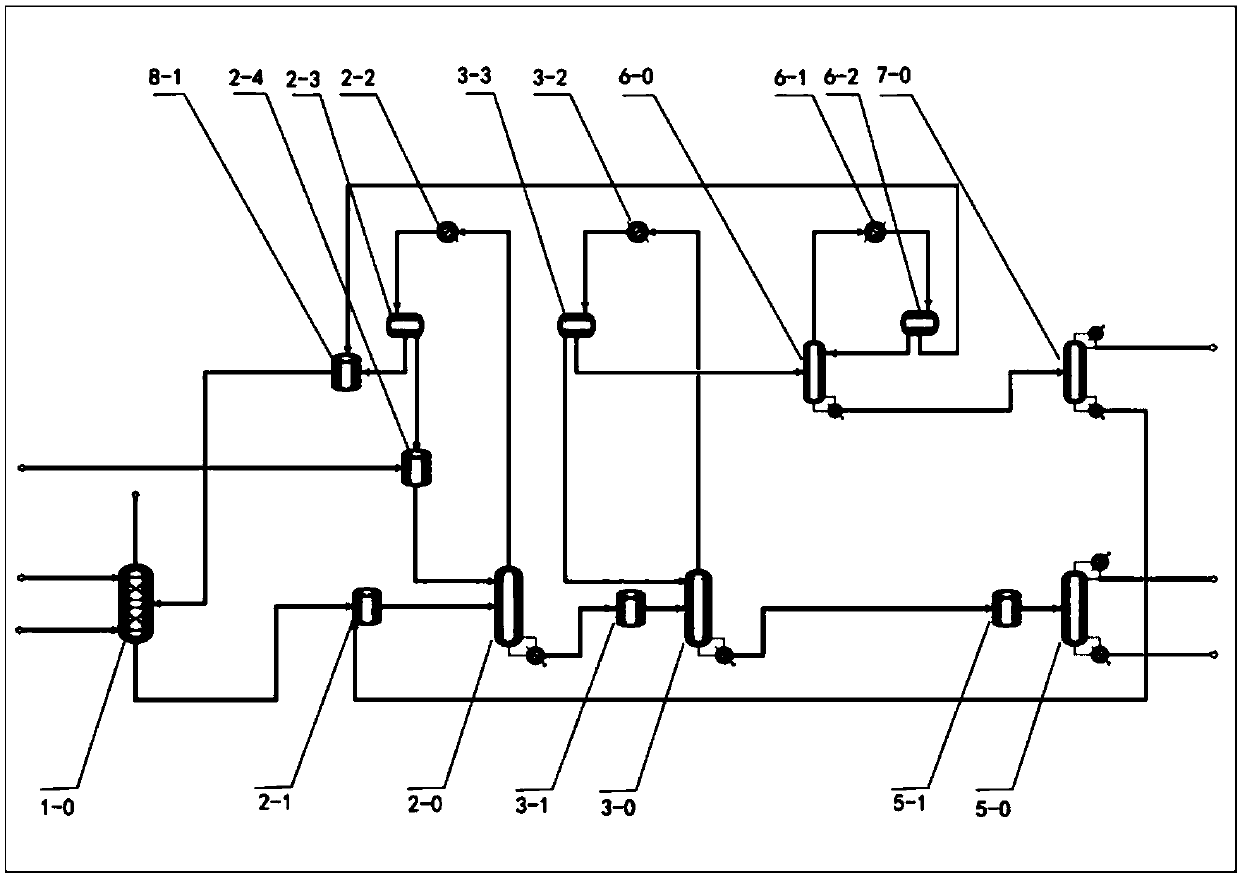

[0038] Such as figure 2 As shown, a kind of acrylic acid refining device with zero discharge of waste water, the device is the same as Example 1, the only difference is that the second circulation system also includes an acetic acid concentration tower 6-0, a third condenser 6-1, The third layerer 6-2 and the acetic acid deweighting tower 7-0; the water phase outlet of the second layerer 3-3 is connected with the inlet of the acetic acid concentration tower 6-0; the acetic acid extraction The top outlet of the concentrated tower 6-0 is connected with the inlet of the third condenser, the outlet of the third condenser 6-1 is connected with the inlet of the third stratifier 6-2, and the third condenser 6-1 is connected with the inlet of the third stratifier 6-2. The water phase outlet of the three stratifiers 6-2 is connected with the water phase storage tank 8-1, and the solvent phase outlet of the third stratifier 6-2 is connected with the acetic acid concentration tower 6-0 ...

Embodiment 3

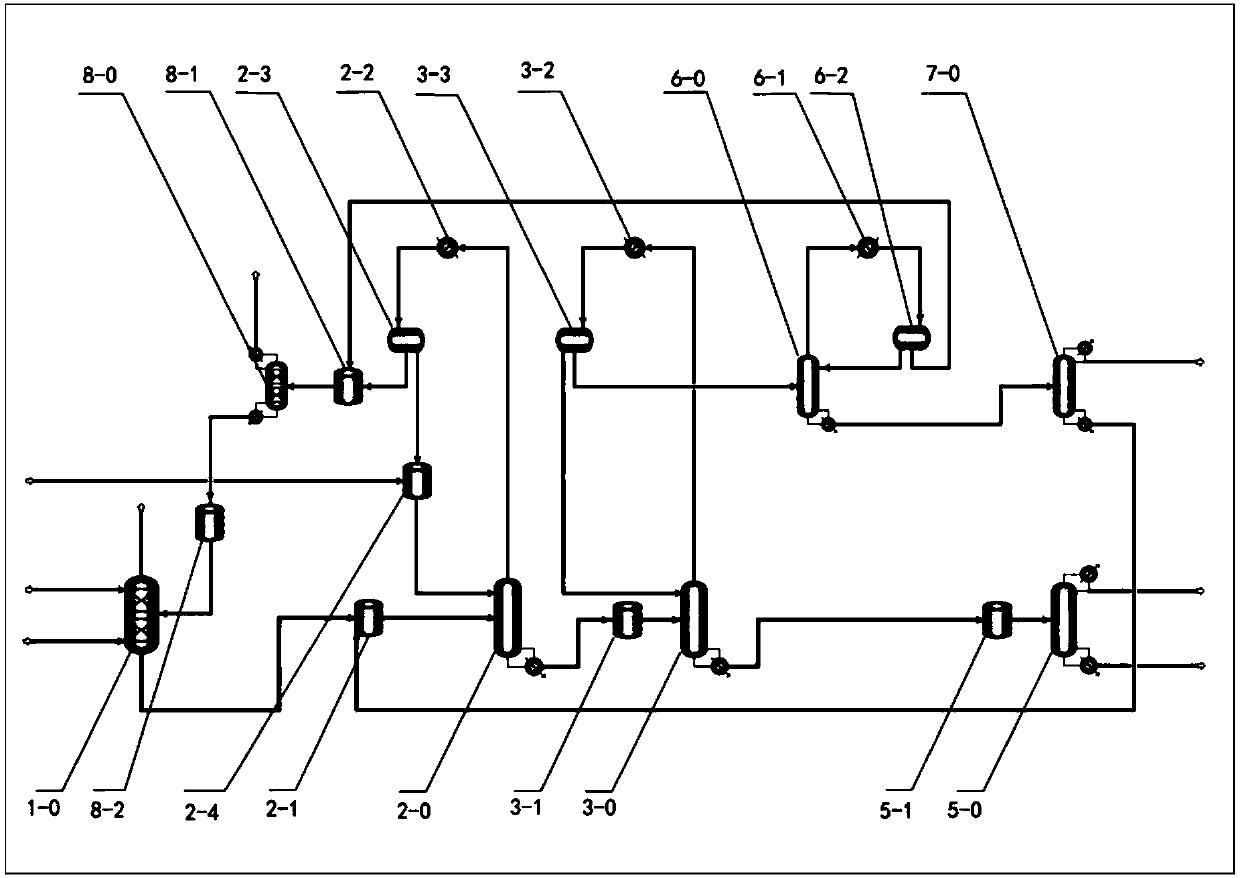

[0040] Such as image 3 As shown, an acrylic acid refining device with zero discharge of waste water is the same as in Example 2, except that the first circulation system also includes a stripper 8-0 and a recovered water storage tank 8-2; The outlet of the water phase storage tank 8-1 is connected with the inlet of the stripping tower 8-0; the bottom outlet of the stripping tower 8-0 passes through the recovery water storage tank 8-2 and the absorption tower 1-0 for the central entrance to connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com