Method and system for lowering laser welding residual stress by coupling high-energy pulse current

A pulse current and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as coarse microstructure defects, achieve the effects of reducing residual stress, improving work efficiency, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

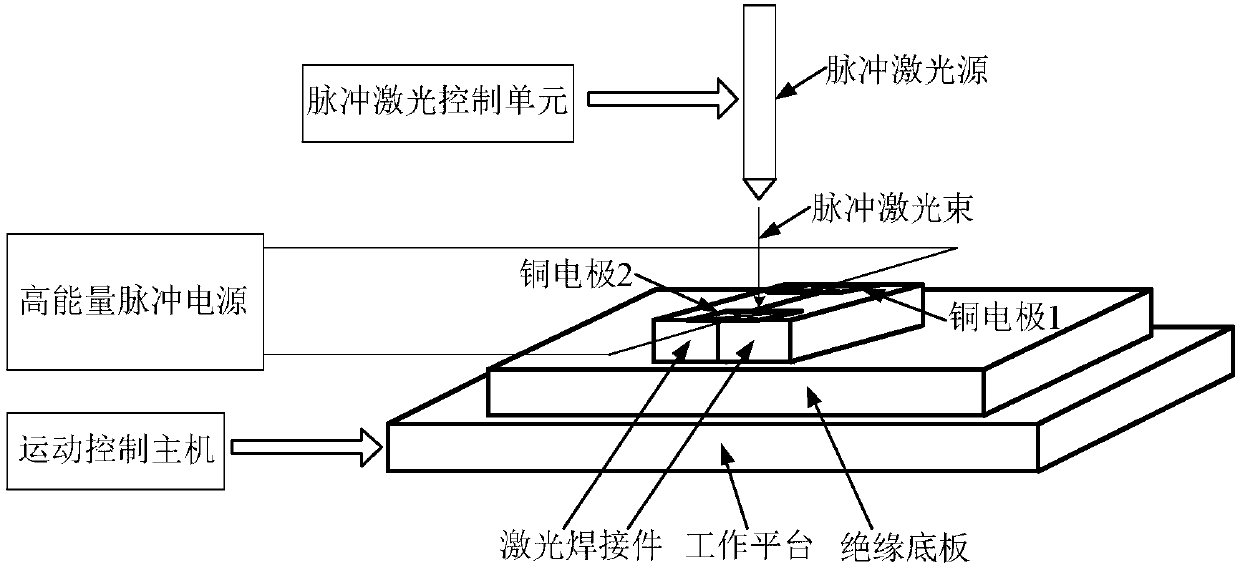

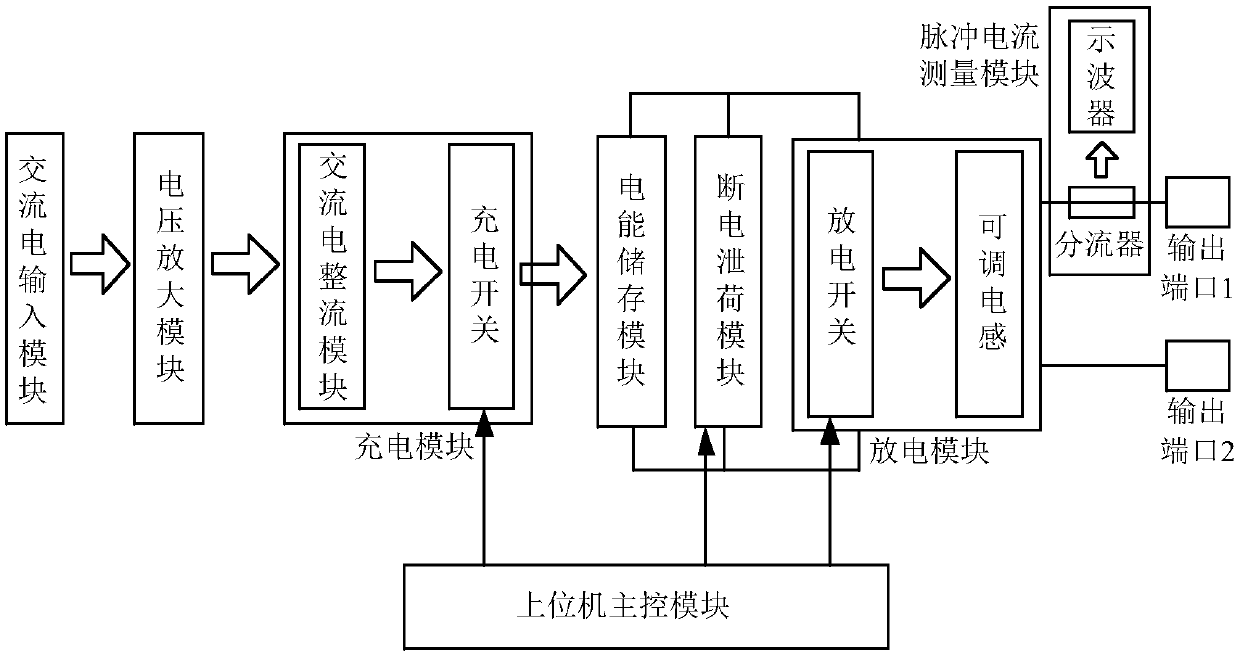

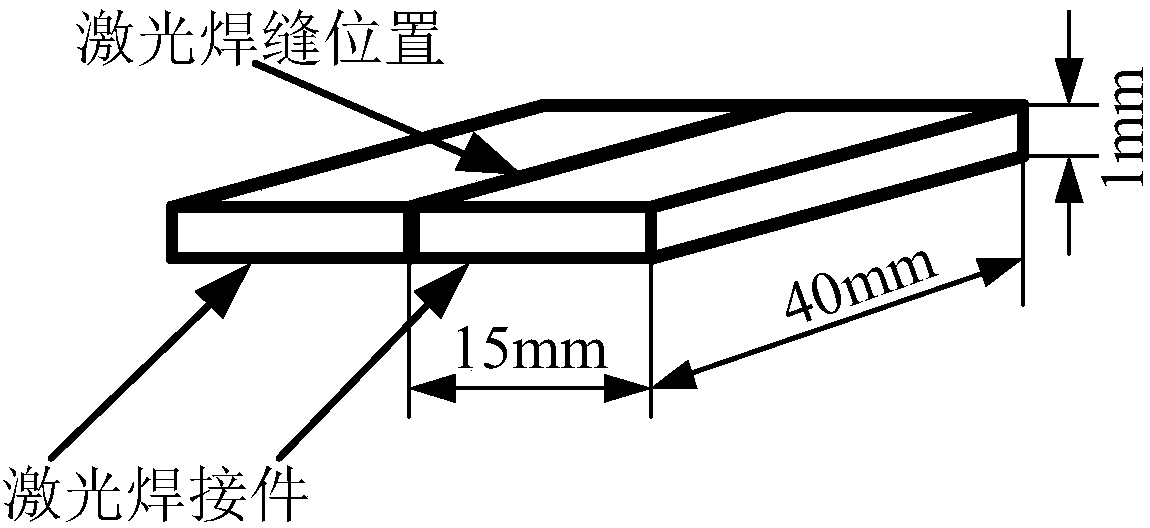

[0034] With reference to accompanying drawing, further illustrate the present invention:

[0035] The method for coupling high-energy pulse current to reduce laser welding residual stress is characterized in that: focusing the laser spot on the weld seam of the workpiece, and performing laser welding on the workpiece; while performing laser welding on the workpiece, applying high-energy pulse current to the weld seam molten pool; after the laser welding is completed, when the weld seam temperature drops below 100°C, the high-energy pulse current is stopped; the high-energy pulse current is a high-energy pulse current that attenuates and oscillates.

[0036] The method for coupling high-energy pulse current to reduce laser welding residual stress is characterized in that: the peak value of the high-energy pulse current I=1-200kA, the width of the high-energy pulse current t=50-200μs, the The pulse repetition frequency is f=0.1~1Hz.

[0037] The method for coupling high-energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com