U type silicon carbon rod

A silicon carbide rod, U-shaped technology, applied in the direction of heating element, heating element shape, ohmic resistance heating parts, etc., can solve the problems of silicon carbide rod material brittleness, uneven vibration fracture, etc., to improve the connection stability and improve the overall The effect of strength and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

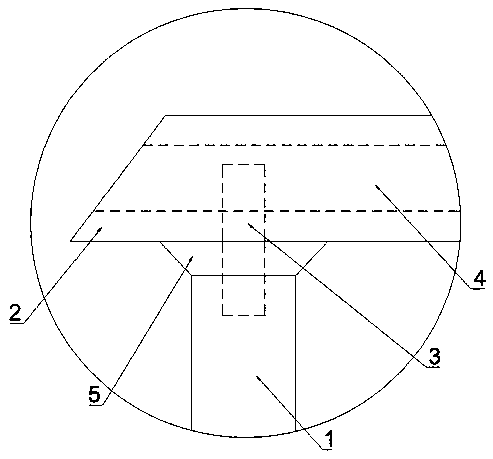

[0015] see Figure 1-2 The U-shaped silicon carbide rod shown includes a vertically connected heating part 1 and a connecting part 2. There are two heating parts 1, one end is an electrode, and the other end is connected to both ends of the connecting part 2 by tenon joints. The connection end is provided with a square connector 3, and a connection plate 4 is built in the connection part 2, and a slot corresponding to the square connector 3 is provided at the corresponding position, and the connection between the heating part 1 and the connection part 2 is welded by external welding Out of the annular reinforcing ring 5, both ends of the connecting portion 2 are also provided with chamfers.

[0016] In the present invention, the mortise joint structure of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com