Preparation method for self-supporting porous electrode, and self-supporting porous electrode and application thereof

A porous electrode, self-supporting technology, applied in the direction of electrode manufacturing, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems of hindered ion and electron transmission, difficult to make electrodes, poor capacity, etc., and achieve controllable electrode thickness , Improve energy density, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

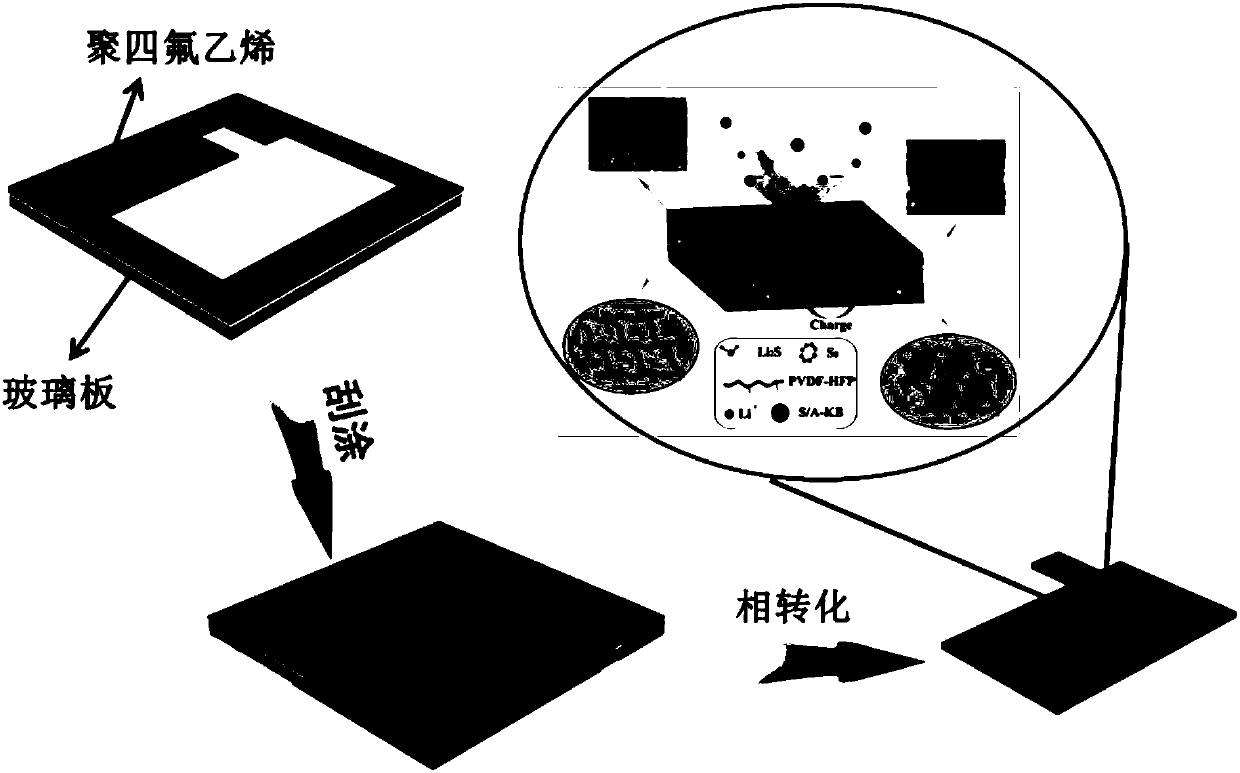

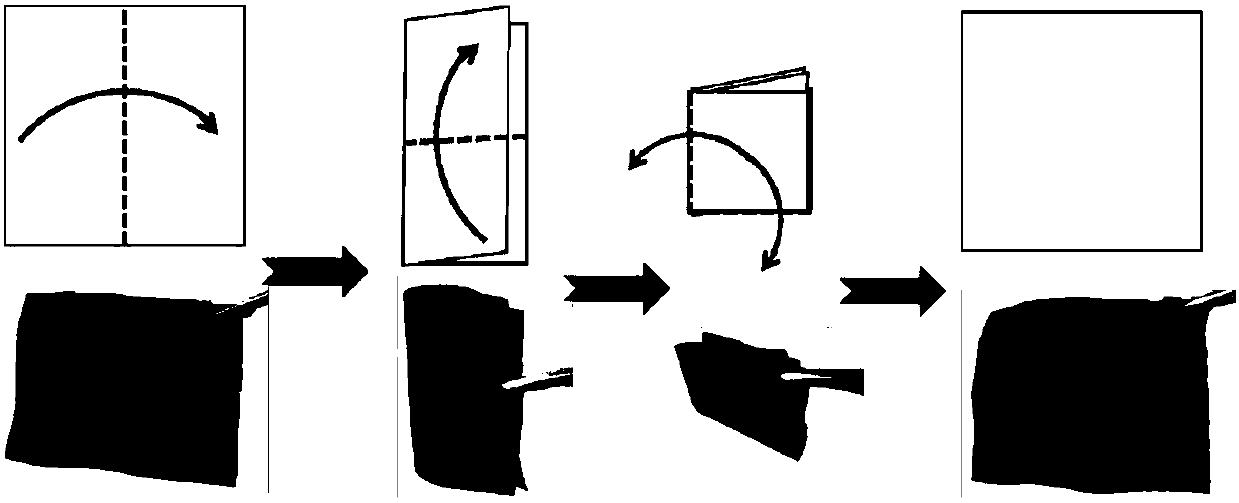

[0053] Dissolve 0.8g PVDF-HFP in 17g N-methylpyrrolidone (NMP), stir until completely dissolved, add 0.4g KB600, stir for 10min, then add 2.8g steam-activated KB600 carbon powder and sulfur complex (S / A-KB600), stir for 5 hours to make it a uniform slurry, adjust the scraper to 0μm, scrape and coat the glass plate with grooves (groove depth: 300μm, diameter: 14mm) repeatedly for 3 times, and wait for the groove to be filled After the slurry is filled, put the glass plate in water. After the slurry disk is separated from the glass plate, it is quenched with liquid nitrogen, and placed in a freeze dryer for 12 hours, dried overnight at 70°C, and weighed at 60 ℃ vacuum drying for 24h. Subsequent battery assembly and testing were the same as in Comparative Example 1.

[0054] Under 0.1C rate, the first discharge specific capacity is 1201mA h g -1 , the specific capacity was maintained at 900mA hg after 50 cycles -1 , the capacity retention rate is 75.0%; when the rate is incre...

Embodiment 2

[0056] Dissolve 0.8g of PVDF-HFP in 17g of N-methylpyrrolidone (NMP), stir until completely dissolved, add 0.4g of MWCNTs (diameter: 8-15nm, length: 20-30μm), stir for 10min, then add 2.8g of S / A -KB600, stir for 5 hours to make it a uniform slurry. Subsequent electrode preparation, battery assembly and testing are the same as in Example 1.

[0057] Under 0.1C rate, the first discharge specific capacity is 1199mA h g -1 , the specific capacity was maintained at 833mA hg after 50 cycles -1 , the capacity retention rate is 73.6%; when the rate is increased to 1C, the discharge specific capacity is 779mA h g -1 .

Embodiment 3

[0059] Dissolve 0.8g of PAN in 17g of N-methylpyrrolidone (NMP), stir until completely dissolved, add 0.4g of KB600, stir for 10min, then add 2.8g of S / A-KB600, stir for 5h to make a uniform slurry. Subsequent electrode preparation, battery assembly and testing are the same as in Example 1.

[0060] Under 0.1C rate, the first discharge specific capacity is 1186mA h g -1 , the specific capacity was maintained at 1058mA hg after 50 cycles -1 , the capacity retention rate is 89.2%; when the rate is increased to 1C, the discharge specific capacity is 699mA h g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com