Insulating full inorganic binder for metal soft magnetic powder core and use method thereof

An inorganic adhesive and metal soft magnetic technology, which is applied in the field of insulating all-inorganic adhesives, can solve the problems of poor water resistance of phosphate, affecting mechanical and magnetic properties, and changes in the performance of magnetic powder cores, so as to improve mechanical strength, Excellent magnetic properties and mechanical properties, the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

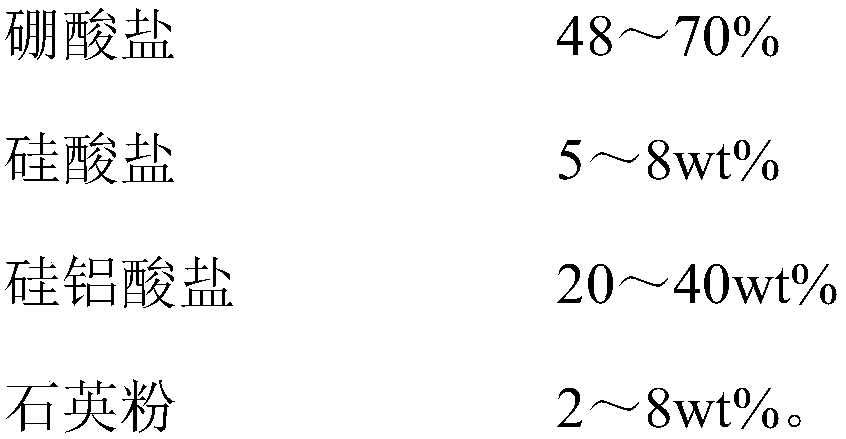

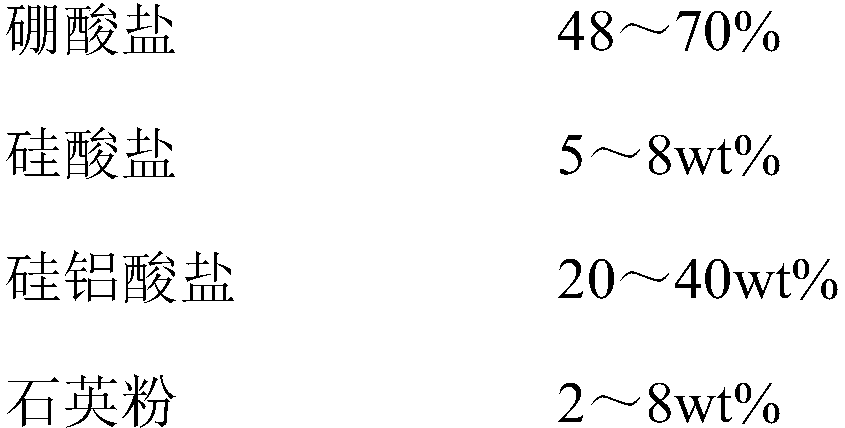

[0022] 1) Mix anhydrous sodium tetraborate, sodium silicate, mica, and albite with a particle size of less than 3 microns and passivated sendust metal powder, wherein the inorganic binder accounts for 2.0% of the total mass of the magnetic powder. The mass composition of the inorganic binder is as follows: anhydrous sodium tetraborate accounts for 50 wt%, sodium silicate accounts for 6 wt%, mica accounts for 20 wt%, albite feldspar 20 wt%, and quartz powder 4 wt%. At the same time, 0.3 wt% of the total mass of the metal magnetic powder was added as a release agent zinc stearate.

[0023] 2) The uniformly mixed powder is made into a ring green body. The dimensions of the annular green body are: outer diameter 26.9mm, inner diameter 14.73mm, height 11.15mm. The annular body is heat-treated in a nitrogen atmosphere, and cooled to obtain a sendust magnetic powder core.

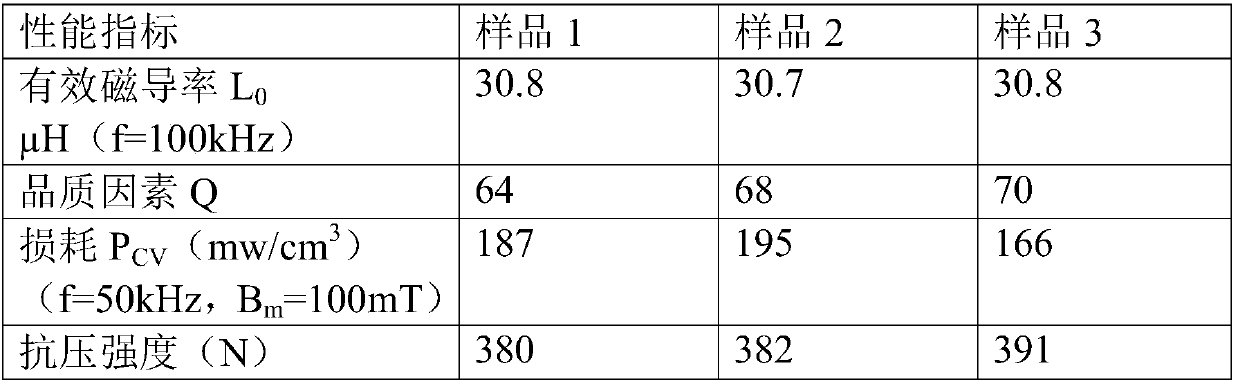

[0024] Three tests were carried out on the parallel samples of the finally prepared sendust magnetic powder c...

Embodiment 2

[0027] 1) Mix anhydrous sodium tetraborate, sodium silicate, kaolin, talc, and quartz with a particle size of less than 3 microns with passivated sendust metal powder, wherein the inorganic binder accounts for 2.2% of the total mass of the magnetic powder. The mass composition of the inorganic binder is: anhydrous sodium tetraborate accounts for 60 wt%, sodium silicate accounts for 6 wt%, mica accounts for 15 wt%, potassium feldspar 6, kaolin accounts for 9 wt%, and quartz powder accounts for 4 wt%. At the same time, 0.3 wt% of the total mass of the magnetic powder was added as a release agent zinc stearate.

[0028] 2) The uniformly mixed powder is pressed into a ring green body. The dimensions of the annular green body are: outer diameter 33.00mm, inner diameter 19.90mm, height 10.67mm. The annular body is heat-treated in a nitrogen atmosphere to obtain a sendust magnetic powder core. Three tests were carried out on the parallel samples of the finally prepared sendust magn...

Embodiment 3

[0031] 1) Mix anhydrous sodium tetraborate, sodium silicate, kaolin, talc, and quartz with a particle size of less than 3 microns and passivated iron-silicon metal powder, wherein the inorganic binder accounts for 2.2% of the total mass of the magnetic powder. The mass composition of the inorganic binder is: 65 wt% of anhydrous sodium tetraborate, 7 wt% of sodium silicate, 10 wt% of kaolin, 10 wt% of talc, and 8 wt% of quartz powder. At the same time, 0.3 wt% of the total mass of the magnetic powder was added as a release agent zinc stearate.

[0032] 2) The uniformly mixed powder is pressed into a ring green body. The dimensions of the annular green body are: outer diameter 17.27mm, inner diameter 9.65mm, height 6.35mm. The annular blank is heat treated in a nitrogen atmosphere, and cooled to obtain a ferrosilicon magnetic powder core.

[0033] Three tests were carried out on the parallel samples of the iron-silicon magnetic powder cores finally prepared, and the properties...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com