Biogas project big data platform system and method

A big data platform and biogas technology, applied in the field of biogas engineering, can solve problems such as untimely information sharing, extensive operation management, lack of effective communication between enterprises, experts and the government, and achieve the effect of reducing fermentation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

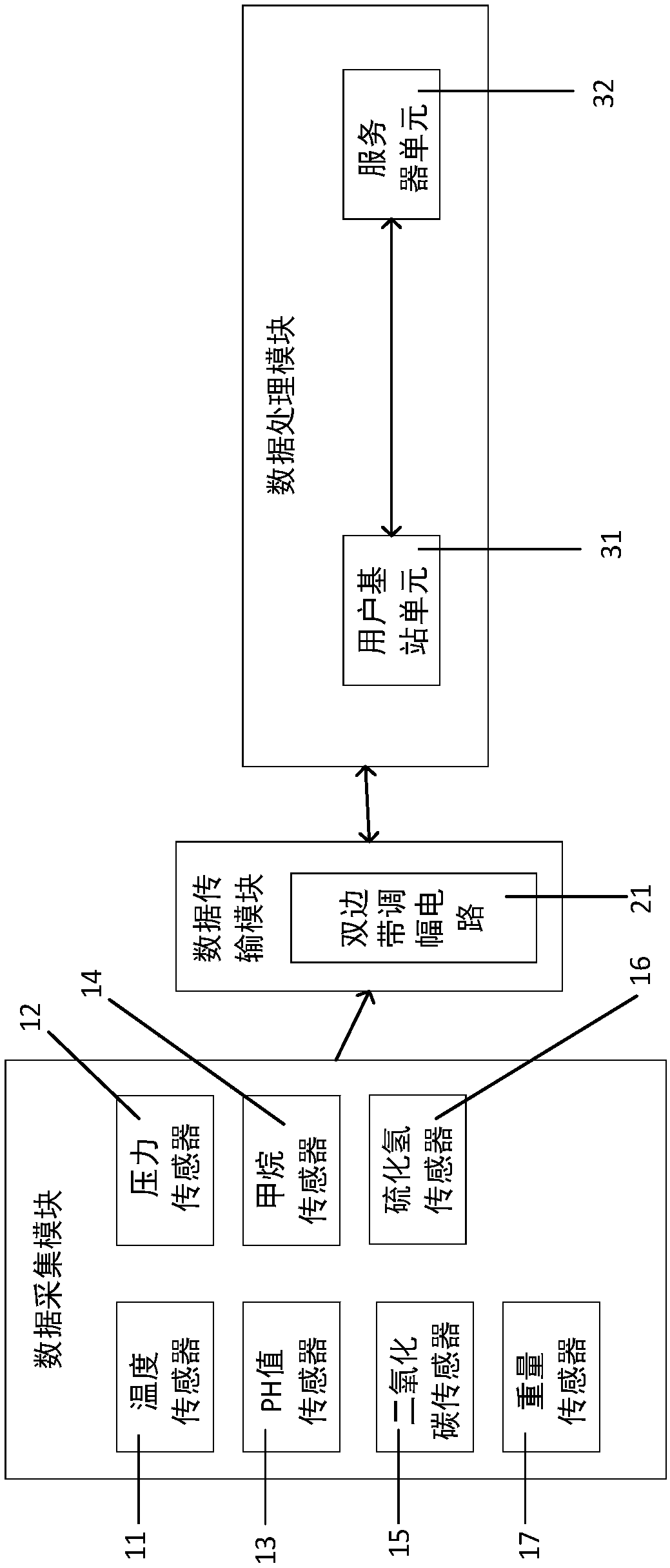

[0028] A biogas project big data platform system, such as figure 1 Shown, comprise data acquisition module, data transmission module and data processing module; Described data acquisition module connects data processing module by data transmission module; Described data acquisition module comprises temperature sensor 11, pressure sensor 12, pH value sensor 13, methane Sensor 14, carbon dioxide sensor 15, hydrogen sulfide sensor 16 and weight sensor 17, data transmission module includes double side band amplitude modulation circuit 21, and described data processing module includes user base unit 31 and server unit 32, and described user base unit 31 is a PC , the minimum number of user base station units 31 is one, the server unit 32 is a server, and the user base station unit 31 is connected to the server unit 32 through wireless.

[0029] Working principle: through temperature sensor 11, pressure sensor 12, PH value sensor 13, methane sensor 14, carbon dioxide sensor 15, hydr...

specific Embodiment approach 2

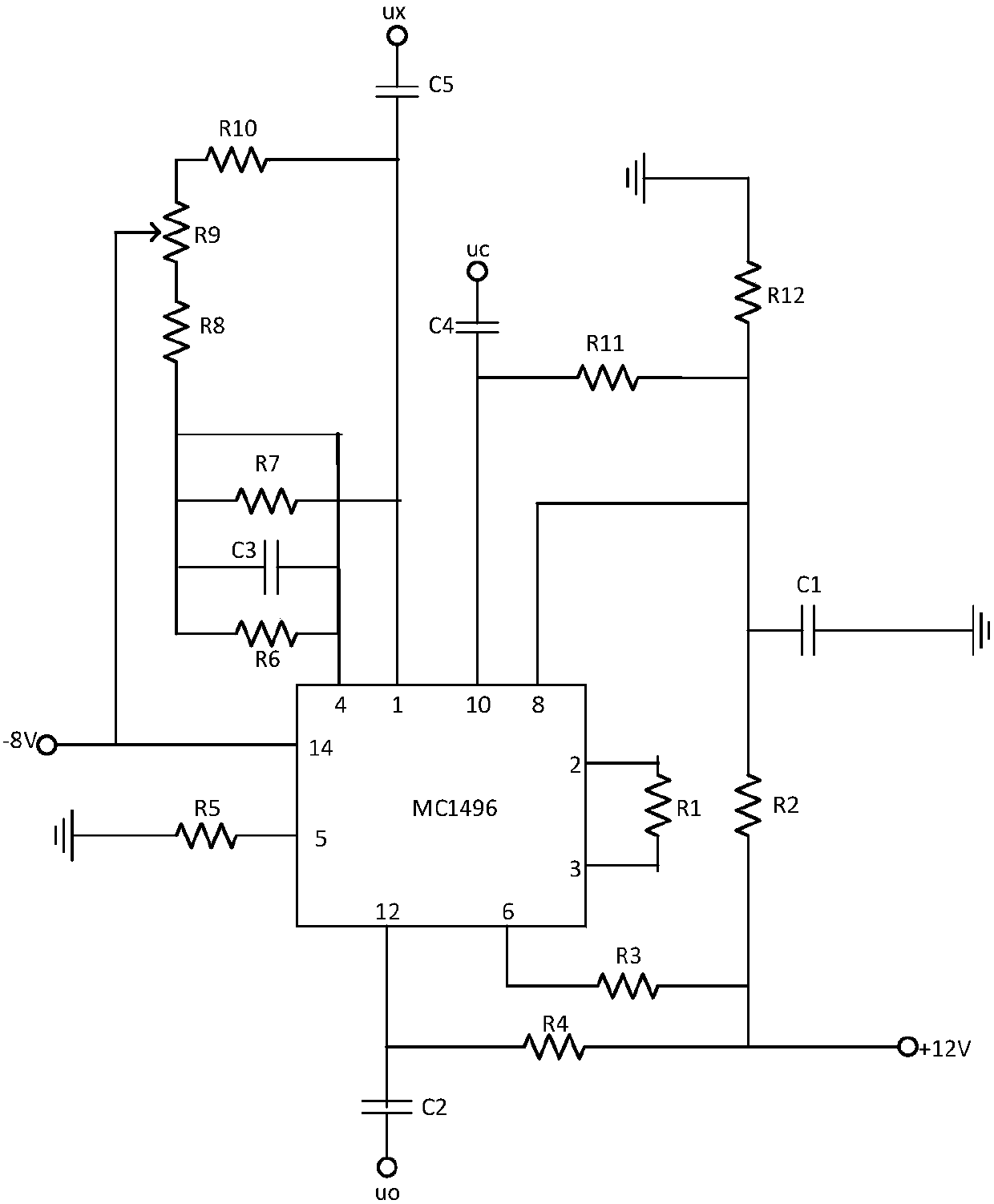

[0030] Specifically, the biogas project big data platform system, such as figure 2 As shown, the double sideband amplitude modulation circuit 21 includes a multiplier MC1496, a resistor R1, a resistor R2, a resistor R3, a resistor R4, a resistor R5, a resistor R6, a resistor R7, a resistor R8, a resistor R9, a resistor R10, a resistor R11, a resistor R12 , capacitor C1, capacitor C2, capacitor C3, capacitor C4 and capacitor C5; the value of resistor R1 is 1kΩ, the value of resistor R2 is 1kΩ, the value of resistor R3 is 3.3kΩ, the value of resistor R4 is 3.3kΩ, the value of resistor R5 is 680kΩ, and the value of resistor R6 The value of resistor R7 is 1kΩ, the value of resistor R7 is 1kΩ, the value of resistor R8 is 750Ω, the value of resistor R9 is 47KΩ, the value of resistor R10 is 750Ω, the value of resistor R11 is 51Ω, the value of resistor R12 is 1kΩ, the value of capacitor C1 is 0.1μF, and the value of capacitor C2 is 0.1 μF, the value of capacitor C3 is 20 μF, the valu...

specific Embodiment approach 3

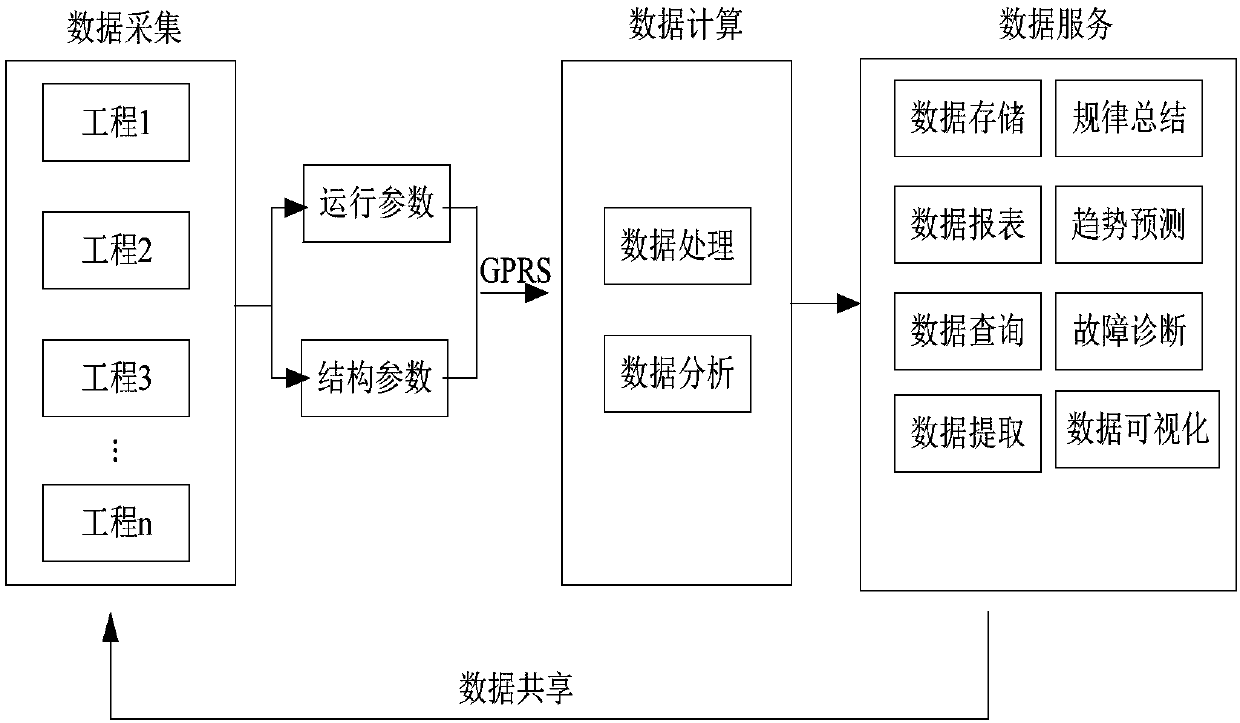

[0031]A method of biogas engineering big data implemented on the biogas engineering big data platform system, comprising the following steps:

[0032] Step a, collect the operating state parameters of the biogas project through the data acquisition module, including data parameters of temperature, pressure, pH value, solid content, gas production rate and biogas composition;

[0033] Step b, the data transmission module transmits the data collected by the data acquisition module to the user base station unit 31;

[0034] Step c. Through on-site research and testing, manually input the process design parameters of the biogas project into the user base station unit 31. The process design parameters include project scale, pretreatment form, fermentation form, fermentation reactor size, insulation design and access Material form;

[0035] Step d, the user base station unit 31 transmits the operating state parameters and process design parameters to the server unit 32 in real time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com