Running-in method for reducing friction coefficient between metal friction pairs

A technology of friction coefficient and friction pair, which is applied in the direction of lubricating composition, engine lubrication, additives, etc., can solve the problems of reducing the service life of metal friction pairs, rusting of metal friction pairs, cumbersome operation, etc., and achieves short running-in time and ultra-low Friction coefficient, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of running-in method that reduces the friction coefficient between metal friction pairs, the steps are as follows:

[0029] Step 1: Clean and dry the friction surface of the metal friction pair with alcohol and acetone respectively to remove the residue on the friction surface; apply 50 μL acetylacetone on the friction surface, and pre-run for 120 seconds. Due to the consumption of acetyl acetone, replenish during the pre-run Three times of acetylacetone to avoid a dry friction state, each replenishment volume is 50 μL; clean the friction surface after pre-running, the surface residues that have not been removed during washing and the reaction products of acetylacetone and the friction surface;

[0030] Step 2: Apply 50 μL of acetylacetone to the friction surface after pre-running, and run for 120 seconds. Due to the consumption of acetylacetone, acetylacetone was supplemented three times (50 μL each time) to avoid dry friction. to 50 μL, then unloa...

Embodiment 2

[0038] As described in Example 1, the difference is: Step 3: Apply 25 μL of SAE 10W-40 engine oil between the friction pairs after running-in, so that the friction pairs are in a fully lubricated state.

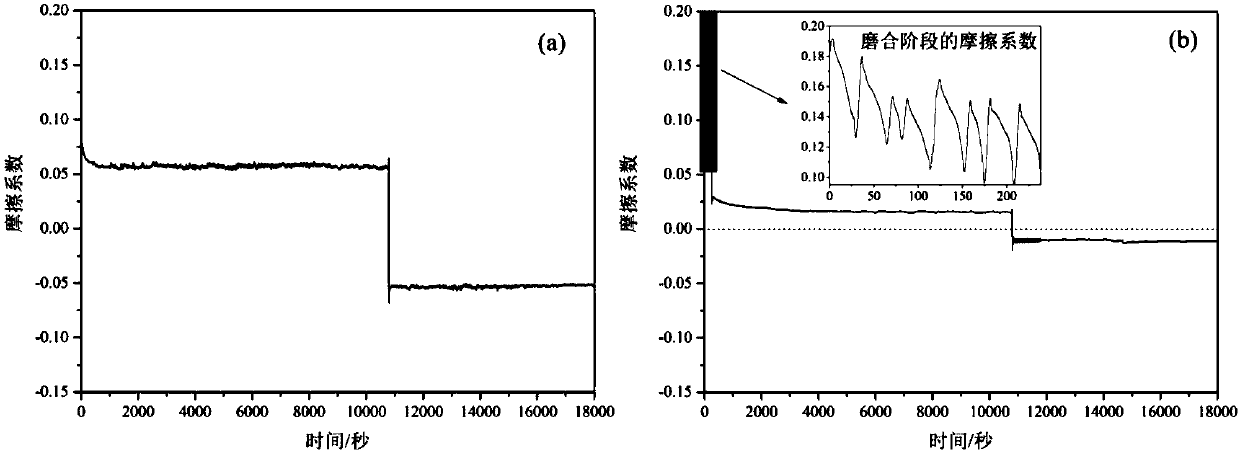

[0039] Start the main engine, the friction pair starts to work, and the friction coefficient after stabilization is 0.052, such as figure 2 (b) shown in the curve. As a comparison, the friction coefficient of the friction pair without running-in by this method is 0.101 under the same conditions, such as figure 2 (a) shown in the curve.

Embodiment 3

[0041] As described in Example 1, the difference is: 25 μL of hexylbiphenylcyanide liquid crystal is used as the lubricant in step 3.

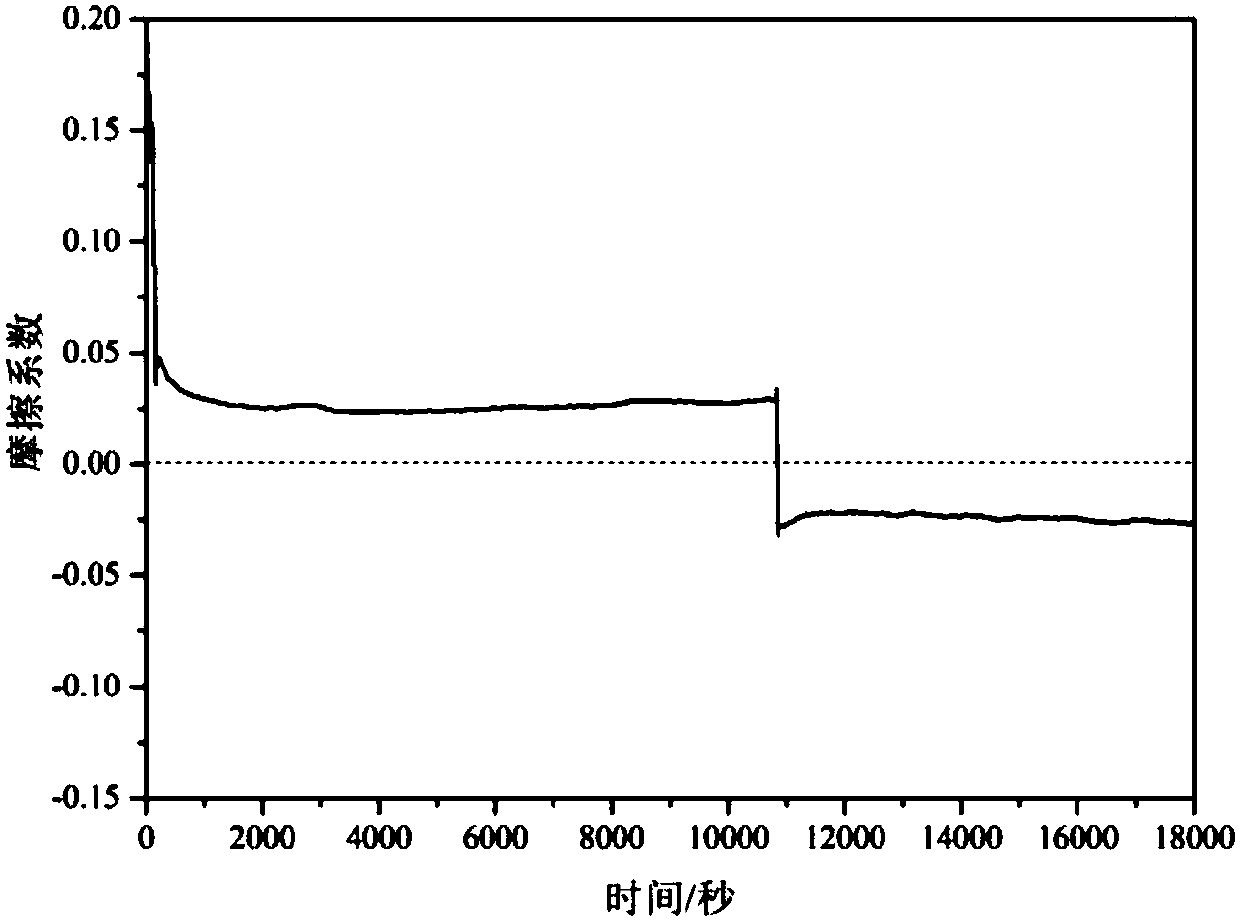

[0042] Start the main engine, the friction pair starts to work, and the friction coefficient after stabilization is 0.021; as a comparison, the friction coefficient of the friction pair that has not been run-in by this method is 0.060 under the same conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com