Long-distance pipeline steep slope region pipe arranging mechanism

A technology for long-distance pipelines and steep slopes, which is applied in the field of pipe layout mechanisms in steep-slope sections of long-distance pipelines. It can solve problems such as equipment damage, casualties, and large swings of tugboats, and achieve reasonable structural design, safe construction process, and reduced safety steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

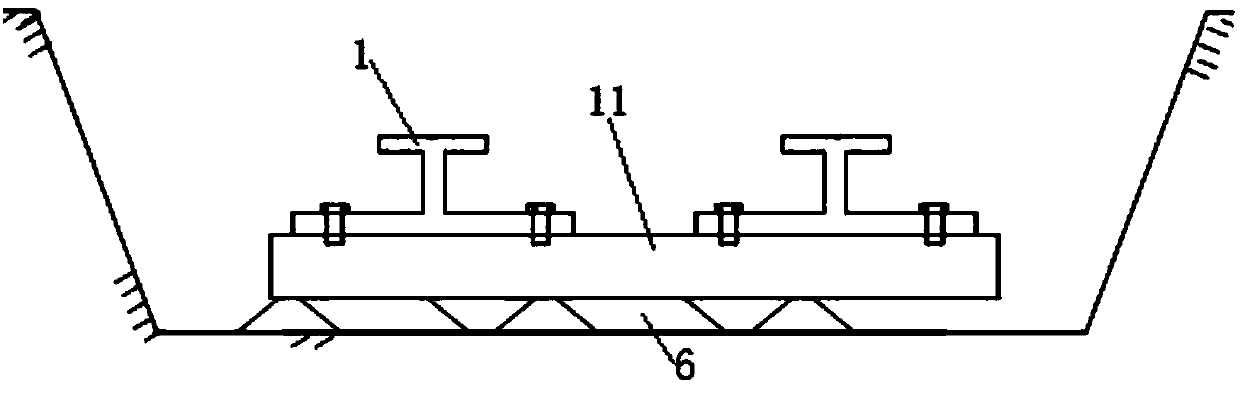

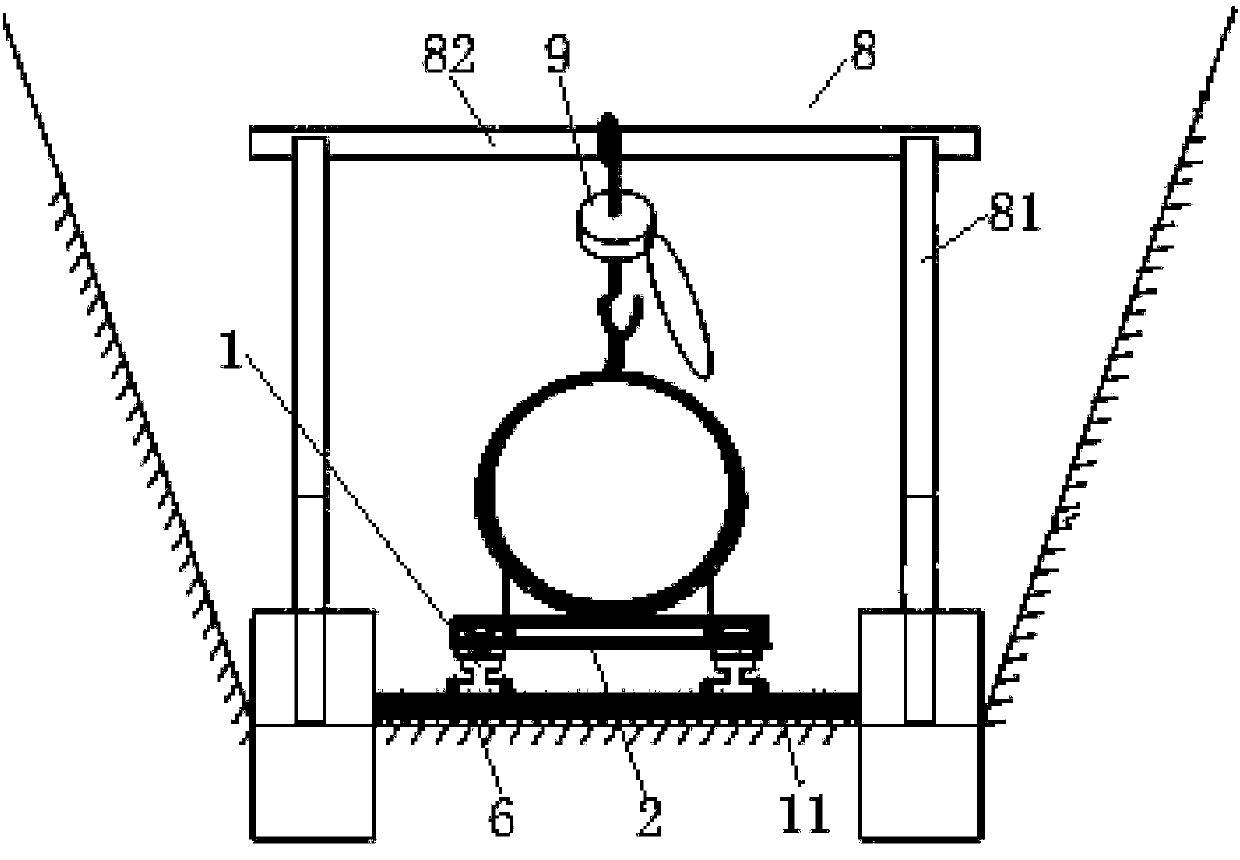

[0031] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0032] Example: such as figure 1 with 2 As shown, the pipe routing mechanism for the steep slope section of the long-distance pipeline of this embodiment is used to install the pipeline in a trench excavated on the foundation along the long direction of the steep slope, and includes a track 1, a mobile trolley 2 and a hoist 3;

[0033] The track 1 is laid on the bottom of the pipe trench along the length of the pipe trench;

[0034] The mobile trolley 2 is located in the pipe trench and can be slidably installed on the rail 1. The pipeline is installed on the mobile trolley 2 along the length of the trench when the pipe is laid;

[0035] The above-mentioned hoist 3 is erected above the foundation at the bottom of the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com