Mounting and reinforcing structure of plug formwork of steel formwork trolley of power generating tunnel

A technology of steel mold trolley and plug formwork, which is applied in shaft equipment, shaft lining, tunnel lining, etc. It can solve the problems of long continuous working time, long construction time, and large waste of turnover materials, and achieve the improvement of installation and reinforcement quality , Reduce the number of operators and speed up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

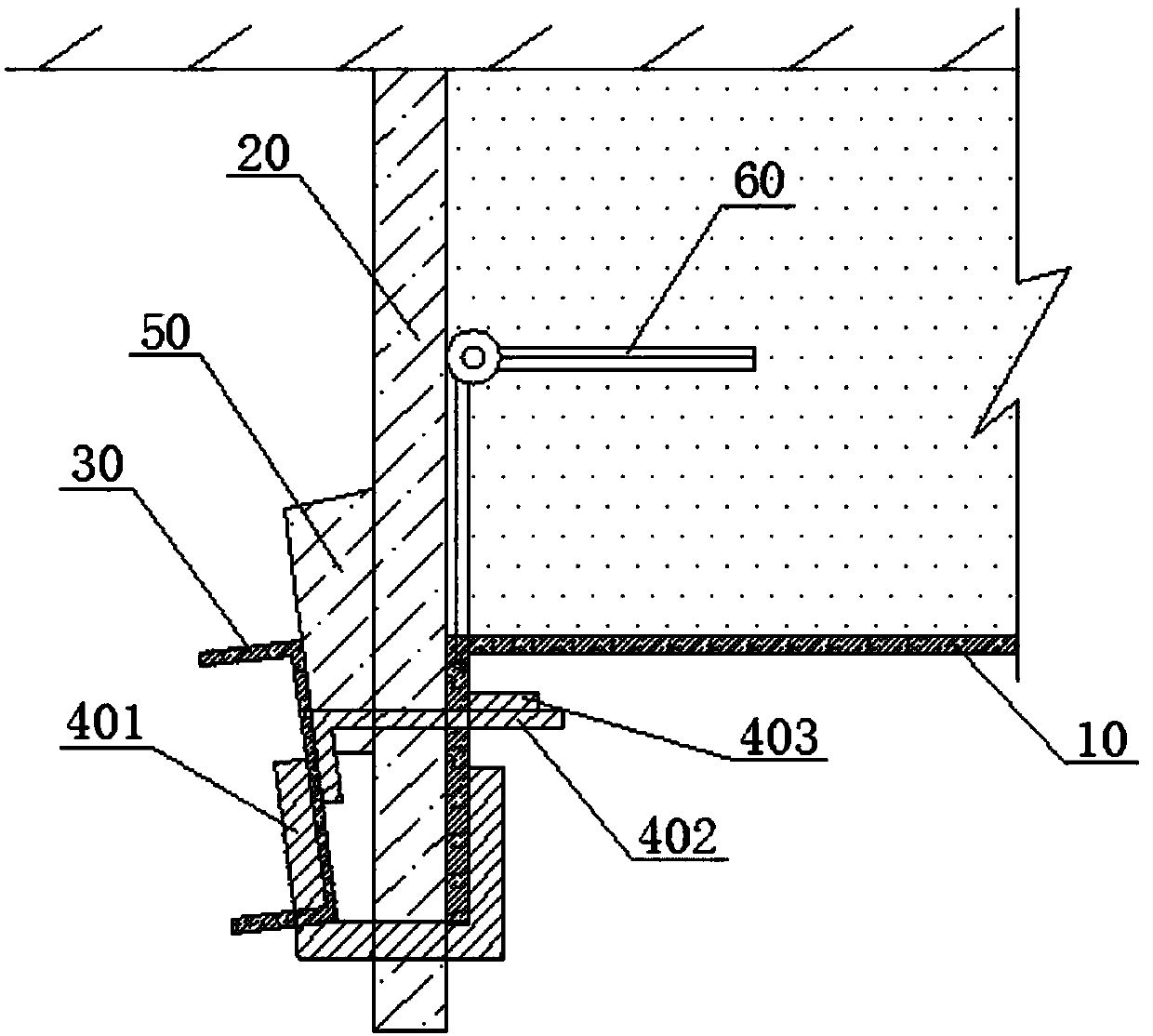

[0019] A power generation tunnel steel mold trolley plug formwork installation and reinforcement structure, such as figure 1 As shown, on the outer side of the 5cm thick wooden plug formwork 20, a plurality of channel steels 30 are arranged along the arc of the steel formwork trolley, and each section of channel steel is fixed on the steel formwork trolley panel 10 by a steel rod, and each section of channel steel 1-2m long.

[0020] A long wooden wedge 50 is arranged between the channel steel 30 and the plug template 20, and the long wooden wedge is used to tighten the wedge. The long wooden wedge is 15-25cm long.

[0021] The steel bar at least includes a first steel bar 401 and a second steel bar 402, the first steel bar 401 is welded around the channel steel 30 and the steel formwork trolley panel 10 from one side, and the second steel bar The rod 402 passes through the steel mold trolley panel 10 and is welded to the back of the channel steel 30; the steel rod also inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com