Method and device for passivating, cooling, destructively distilling and pyrolyzing anthracite coal

An anthracite and pyrolysis technology, applied in the field of coal chemical industry, can solve the problems of poor sealing effect, high water content and temperature of anthracite, and reduce calorific value, so as to maintain effective calorific value, facilitate long-term storage, and improve reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

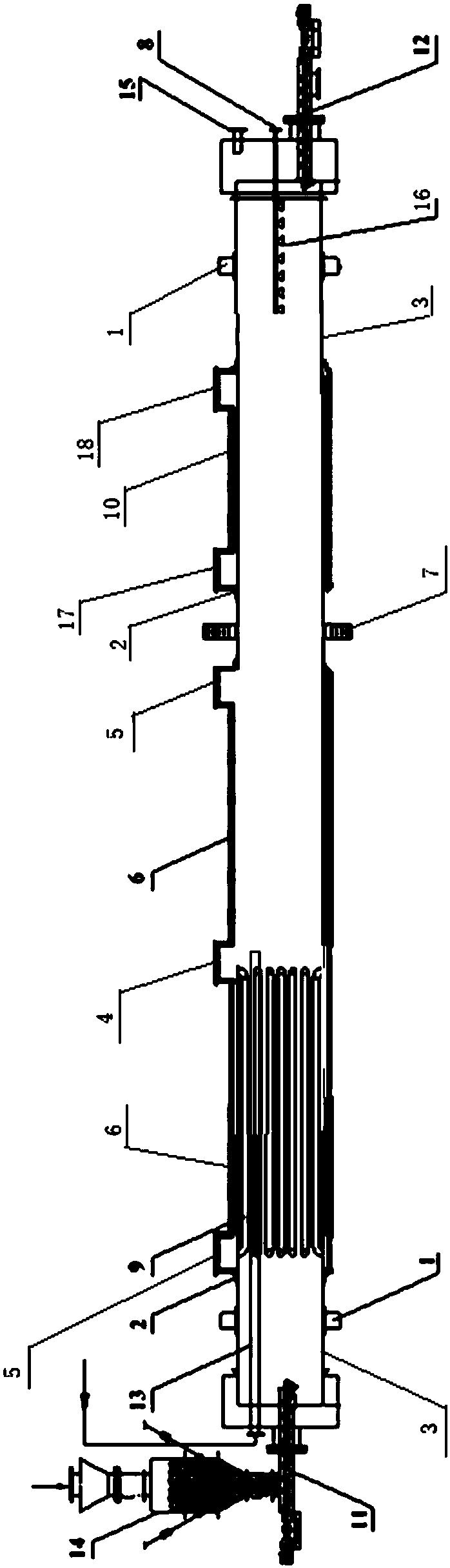

Image

Examples

Embodiment 1

[0036] The method for the passivation cooling dry distillation pyrolysis of anthracite provided in this embodiment comprises the following steps:

[0037] (1) cooling the anthracite after pyrolysis at 550°C to 250°C to obtain pretreated anthracite;

[0038] (2) reacting the anthracite pretreated in step (1) with an inert gas to activate the anthracite with oxygen to form a medium-temperature passivated anthracite at 110°C; wherein, the inert gas is flue gas and air at 120°C Or a mixture of nitrogen, the volume fraction of oxygen in the inert gas is 8%;

[0039] Then passivate the medium-temperature passivated anthracite at 110° C. to obtain anthracite at 220° C., wherein the temperature rise rate during the passivation process is 5° C. / min;

[0040] (3) cooling and hydrating the 220° C. anthracite of the step (2) with cooling water at 0° C. to obtain a low-temperature passivated anthracite with a water content of 4 wt % and a temperature of 45° C.;

[0041] Wherein, the mass...

Embodiment 2

[0043] The method for the passivation cooling dry distillation pyrolysis of anthracite provided in this embodiment comprises the following steps:

[0044] (1) cooling the anthracite after pyrolysis at 600°C to 220°C to obtain pretreated anthracite;

[0045] (2) reacting the anthracite pretreated in step (1) with an inert gas to activate the anthracite with oxygen to form a medium-temperature passivated anthracite at 140° C.; wherein the inactive gas is flue gas and air at 80° C. or a mixture of nitrogen, the volume fraction of oxygen in the inert gas is 20%;

[0046] Then passivate the medium-temperature passivated anthracite at 140° C. to obtain anthracite at 170° C., wherein the temperature rise rate during the passivation process is 10° C. / min;

[0047] (3) cooling and hydrating the 170° C. anthracite of the step (2) with cooling water at 0° C. to obtain a low-temperature passivated anthracite with a water content of 5.5 wt % and a temperature of 25° C.;

[0048] Wherein,...

Embodiment 3

[0050] The method for the passivation cooling dry distillation pyrolysis of anthracite provided in this embodiment comprises the following steps:

[0051] (1) cooling the anthracite after pyrolysis at 580°C to 230°C to obtain pretreated anthracite;

[0052] (2) reacting the anthracite pretreated in step (1) with an inert gas to activate the anthracite with oxygen to form a medium-temperature passivated anthracite at 130° C.; wherein the inactive gas is flue gas and air at 100° C. Or a mixture of nitrogen, the volume fraction of oxygen in the inert gas is 12%;

[0053] Then passivate the medium-temperature passivated anthracite at 130° C. to obtain anthracite at 200° C., wherein the temperature rise rate during the passivation process is 8° C. / min;

[0054] (3) cooling and hydrating the 200° C. anthracite of the step (2) with cooling water at 10° C. to obtain a low-temperature passivated anthracite with a water content of 4.5 wt % and a temperature of 31° C.;

[0055] Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com