Crosslinking polyethylene foam cotton material and preparation method thereof

A technology of cross-linked polyethylene and polyethylene, which is applied in the field of polymer materials, can solve the problems of poor mutual solubility, etc., and achieve the effects of improving softness, high tensile strength, and improving melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

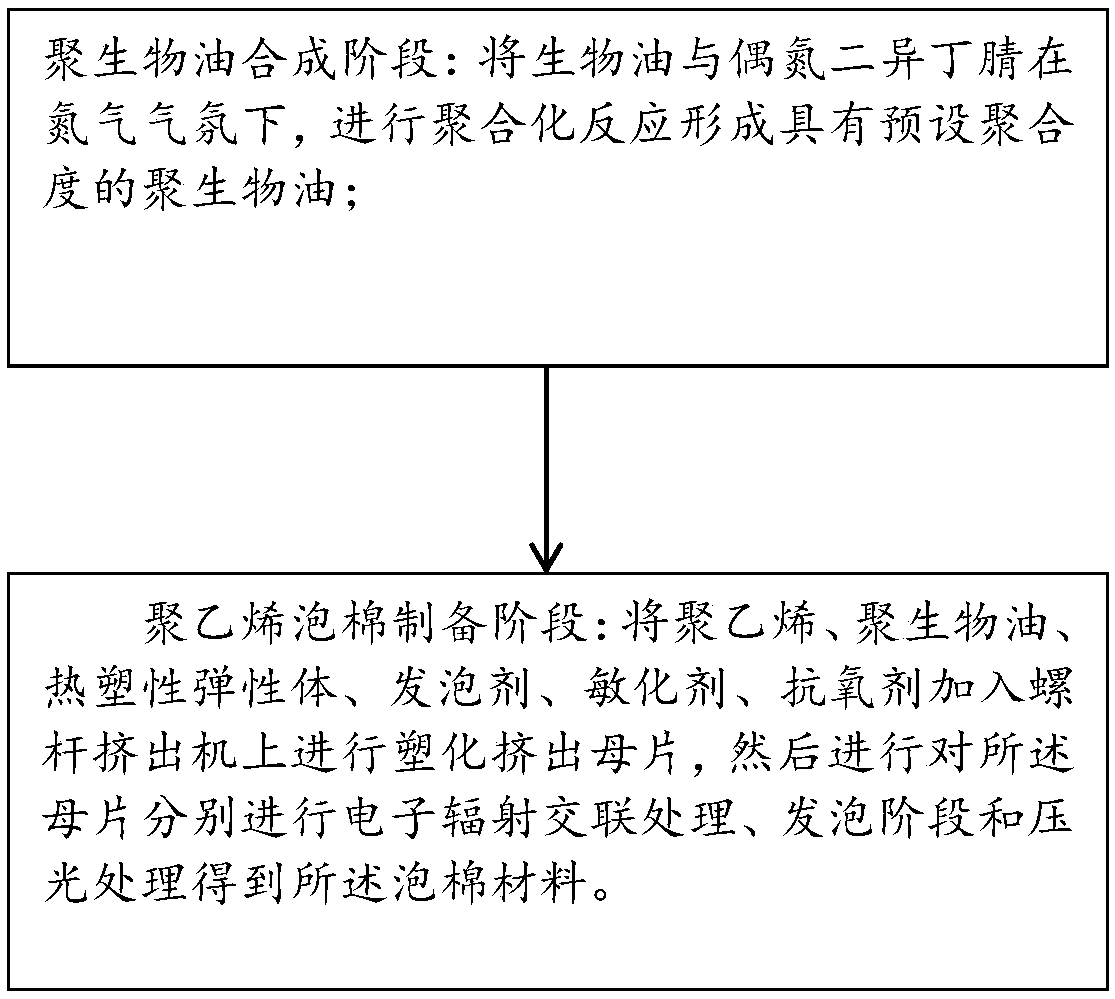

[0038] Such as figure 1 As shown, the preparation method of the cross-linked polyethylene foam material includes the following steps:

[0039] This application also provides a method for preparing the above-mentioned cross-linked polyethylene foam material, and the method includes the following steps:

[0040] (1) Poly-bio-oil synthesis stage: 100 parts by weight of bio-oil and 0.5-1 parts by weight of azobisisobutyronitrile are polymerized in a nitrogen atmosphere at 150-250°C for 2-24 hours to form a preset polymerization Degree of poly bio-oil;

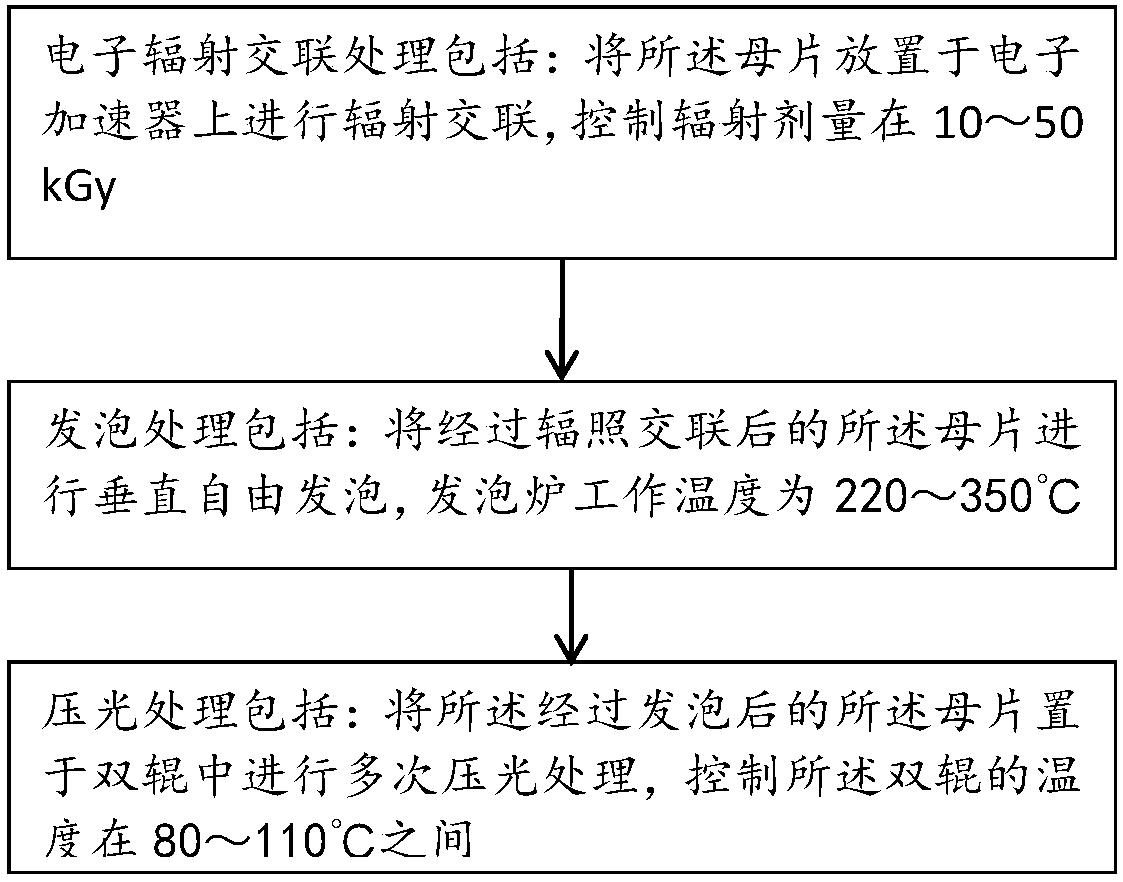

[0041] (2) Polyethylene foam preparation stage: weigh 65-90 parts by weight polyethylene, 1-30 parts by weight polybio-oil, 2-30 parts by weight of thermoplastic elastomer, 0.5-5 parts by weight of foaming agent, 0.5- 4 parts by weight of sensitizer and 1 to 4 parts by weight of antioxidant are added to the screw extruder to plasticize and extrude the mother film, and then the mother film is subjected to electron radiation crosslinking t...

Example Embodiment

[0047] Example one

[0048] Step 1 Synthesis of poly canola oil

[0049] 100 parts by weight of peanut oil and 0.8 parts by weight of azobisisobutyronitrile are placed in the reaction kettle for uniform mixing, and then the air in the reaction kettle is replaced by nitrogen. In a nitrogen atmosphere, the reactor is heated to 320°C, rapeseed oil and azobisisobutyronitrile are polymerized for 8 hours to obtain poly rapeseed oil;

[0050] Step 2 Preparation of Polyethylene Foam

[0051] Weigh the raw materials according to the following parts by weight:

[0052] 75 parts by weight of low density polyethylene;

[0053] 15 parts by weight of poly canola oil;

[0054] 10 parts by weight of EPDM rubber;

[0055] 2.5 parts by weight of azodicarbonamide;

[0056] 1.5 parts by weight of zinc stearate;

[0057] Antioxidant 10102 parts by weight;

[0058] Add the low-density polyethylene, azodicarbonamide, zinc stearate, and antioxidant 1010 to the high-speed mixer according to the above-mentioned weigh...

Example Embodiment

[0062] Example two

[0063] Step 1 Synthesis of poly soybean oil

[0064] 100 parts by weight of soybean oil and 0.6 parts by weight of azobisisobutyronitrile are placed in the reaction kettle for uniform mixing, and then the air in the reaction kettle is replaced by nitrogen. In a nitrogen atmosphere, the reactor is heated to 300°C, and the soybean oil and azobisisobutyronitrile are polymerized for 12 hours to obtain polysoybean oil;

[0065] Step 2 Preparation of Polyethylene Foam

[0066] Weigh the raw materials according to the following parts by weight:

[0067] 70 parts by weight of low density polyethylene;

[0068] 10 parts by weight of poly soybean oil;

[0069] 15 parts by weight of ethylene-octene copolymer;

[0070] Azodicarbonamide 2.8 parts by weight;

[0071] 1.5 parts by weight of barium stearate;

[0072] Antioxidant 10102 parts by weight;

[0073] Add the low-density polyethylene, azodicarbonamide, barium stearate, and antioxidant 1010 to the high-speed mixer according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com