Self-repairing functional additive for concrete and preparation method of functional additive

A self-healing, concrete technology, applied in the field of building materials, can solve the problems of prolonged concrete setting time, large molecular size, and cracks cannot self-repair, etc., to achieve the effect of improving self-repairing ability, strong self-repairing ability and good self-repairing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

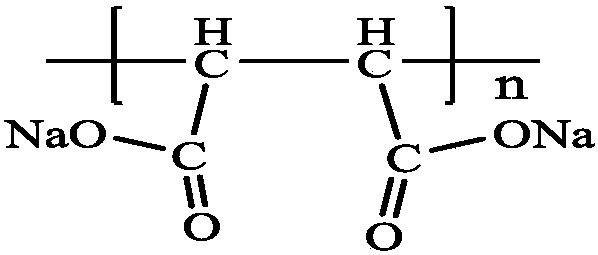

[0025] A concrete self-repairing functional admixture is prepared by the following method: weighing 53 parts of multi-ion complexing agent, 45 parts of calcium bicarbonate, and 2 parts of acrylic acid-acrylamide copolymerized water-absorbing resin, adding them into a mixer and mechanically stirring for 5 minutes to obtain Concrete self-repair function admixture.

Embodiment 2

[0027] A concrete self-repairing functional admixture is prepared by the following method: weighing 53 parts of multi-ion complexing agent, 43 parts of calcium bicarbonate, and 4 parts of acrylic acid-acrylamide copolymerized water-absorbing resin, adding them into a mixer and mechanically stirring for 5 minutes to obtain Concrete self-repair function admixture.

[0028] Weigh cement, gravel, mineral powder, sand, water, water reducing agent and the concrete self-repairing function admixture prepared in Example 1 or Example 2 according to the mass ratio in Table 1. First add crushed stone, sand, mineral powder, cement and self-repairing functional admixture to the concrete mixer and mix for 30 seconds, then add water reducer and water into the mixer and mix for 120 seconds to obtain concrete with crack self-repairing function; the control group The concrete self-repairing function admixture is not added in the concrete, other conditions are the same.

[0029] Freeze-thaw dama...

Embodiment 3

[0037] A concrete self-repairing functional admixture is prepared by the following method: weighing 53 parts of multi-ion complexing agent, 45 parts of calcium bicarbonate, and 3 parts of acrylic acid-acrylamide copolymerized water-absorbing resin, adding them into a mixer and mechanically stirring for 5 minutes to obtain Concrete self-repair function admixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com