Manufacturing process of helical compression eccentric spring and its spring products

An eccentric spring and manufacturing process technology, applied in the direction of springs, manufacturing tools, springs/shock absorbers, etc., can solve the problems of limited spring installation space, increased spring load, and loss of elastic properties of springs, and achieves large use stroke, low pressure and Height, effect of improving design and safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

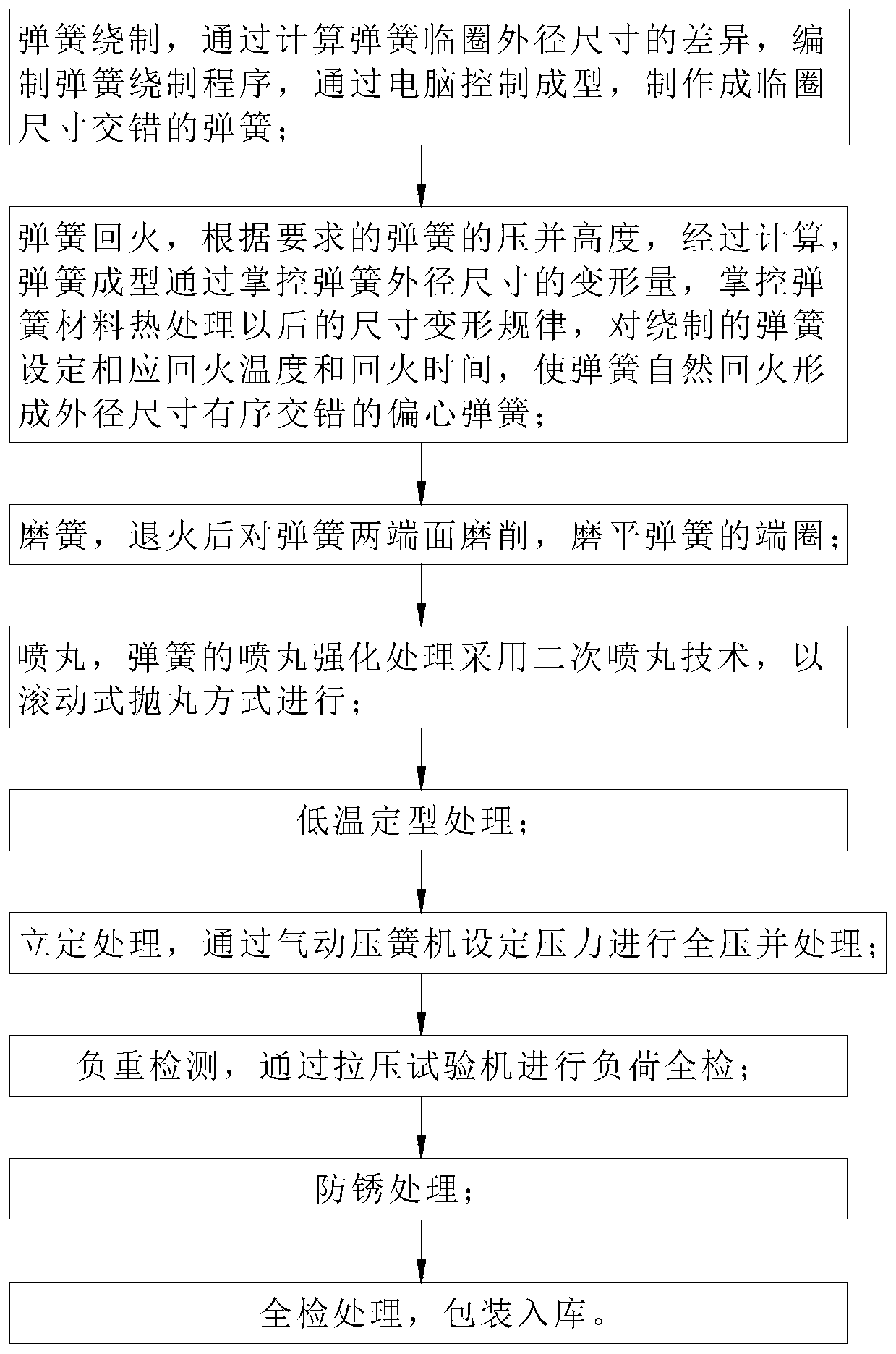

[0046] Such as figure 1As shown, the manufacturing process of the helical compression eccentric spring of the present invention includes the following steps:

[0047] 1. Understand the spring parameters, such as a certain helical compression eccentric spring

[0048] Material: SWOSC-VHS

[0049] Material wire diameter: d=3.7㎜

[0050] Spring size (outer diameter): D2=21.5㎜

[0051] The total number of coils of the spring: n1 = 52 coils

[0052] Number of effective coils of spring: n=48 coils

[0053] Spring hardness: HRC48~53

[0054] Spring free height: H0=332.8mm

[0055] Spring working height: H1=188mm

[0056] Spring working stress: 819N / mm 2

[0057] Spring working stroke: f1=(144.8) mm

[0058] 2. Calculation process

[0059] (1) Select SWOSC-VHS oil quenching material, and the tensile strength standard of the material is: 2060-2160MPa

[0060] (2) Calculate the spring winding ratio C=D / d

[0061] =4.81

[0062] Where: C is the winding ratio of the spring, ...

Embodiment 2

[0096] Such as Figure 4 As shown, the helical compression eccentric spring product of the present invention includes a spring body, the outer diameter of the spring body includes a large outer diameter and a small outer diameter, and the large outer diameter and the small outer diameter form a large coil and a small coil of the spring respectively, and the spring The large circles and small circles are distributed in an orderly and interlaced order to form a helical compression eccentric spring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com