Composition for lining

A composition and lining technology, applied in household appliances, other household appliances, applications, etc., can solve problems such as marine pollution, and achieve the effects of low viscosity, good curing speed, and excellent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

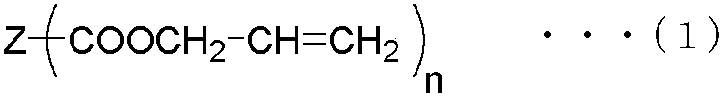

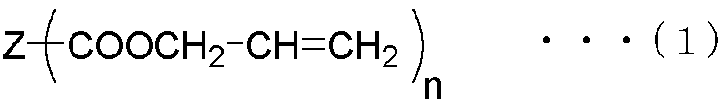

Method used

Image

Examples

Synthetic example 3

[0120] Diallyl itaconate: Synthesis Example 4

[0121] Diallyl 1,2-cyclohexanedicarboxylate: Synthesis Example 5

[0122] Diallyl 1,4-cyclohexanedicarboxylate: Synthesis Example 6

[0123] 1,6-hexanediol dimethacrylate: Kyoeisha Co., Ltd.

Synthetic example 1

[0124] Synthesis example 1: Synthesis of diallyl fumarate

[0125]145.2 g (2.50 mol) of allyl alcohol, 137.5 g (1.49 mol) of toluene, 116.1 g (1.00 mol) of fumaric acid, and 6.53 g (0.02 mol) of dodecylbenzenesulfonic acid were put into a 500 mL flask. Stir with a stir bar and reflux in an oil bath. After 24 hours the heating was turned off and the flask was cooled. The obtained reaction solution was neutralized and washed with water, the low boiling components were distilled off with a rotary evaporator, and the obtained concentrated solution was distilled under reduced pressure to obtain 74.0 g of target diallyl fumarate. The obtained compound was used in Example 2.

[0126] Synthesis example 2: Synthesis of diallyl succinate

[0127] 159.7g (2.75mol) of allyl alcohol, 151.3g (1.64mol) of toluene, 110.1g (1.10mol) of succinic anhydride, and 7.18g (0.022mol) of dodecylbenzenesulfonic acid were put into a 500mL flask, and stirred with a magnetic Stir and reflux in an o...

Synthetic example 4

[0130] Synthesis example 4: Synthesis of diallyl itaconate

[0131] 275.9 g (4.75 mol) of allyl alcohol, 261.3 g (2.83 mol) of toluene, 248.9 g (1.90 mol) of itaconic acid, and 12.41 g (0.038 mol) of dodecylbenzenesulfonic acid were put into a 500 mL flask. Stir with a stir bar and reflux in an oil bath. After 30 hours the heating was turned off and the flask was cooled. The obtained reaction solution was neutralized and washed with water, the low boiling components were distilled off with a rotary evaporator, and the obtained concentrated solution was distilled under reduced pressure to obtain 145 g of target diallyl itaconate. The obtained compound was used in Example 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com