Modular reversing ventilation drying machine

A ventilation drying and modularization technology, which is applied in the directions of local stirring dryers, static material dryers, dryers, etc., can solve the problems of single ventilation direction, large volume, heat waste, etc., to ensure the drying quality and wind field Uniform distribution, avoiding the effect of excessive volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

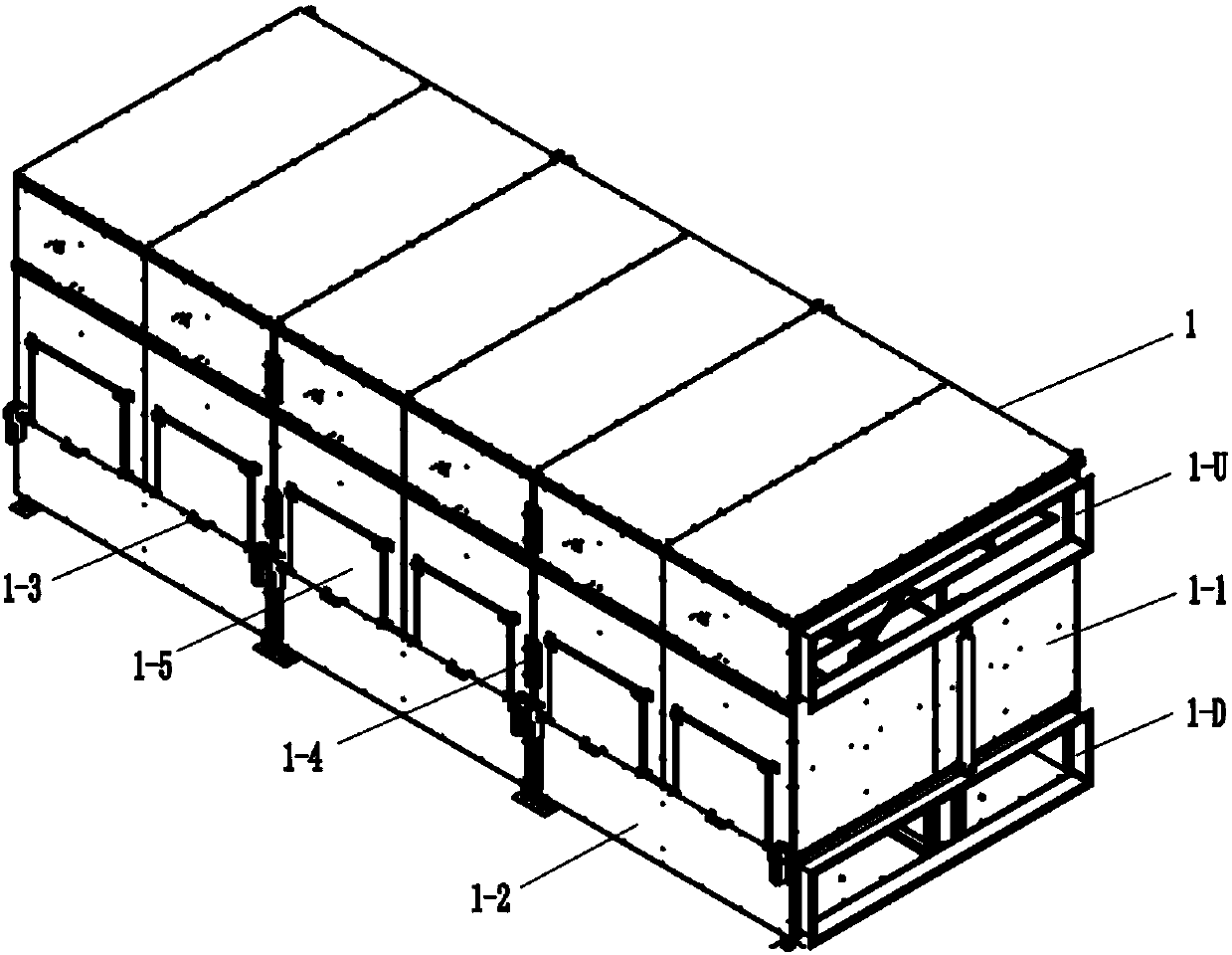

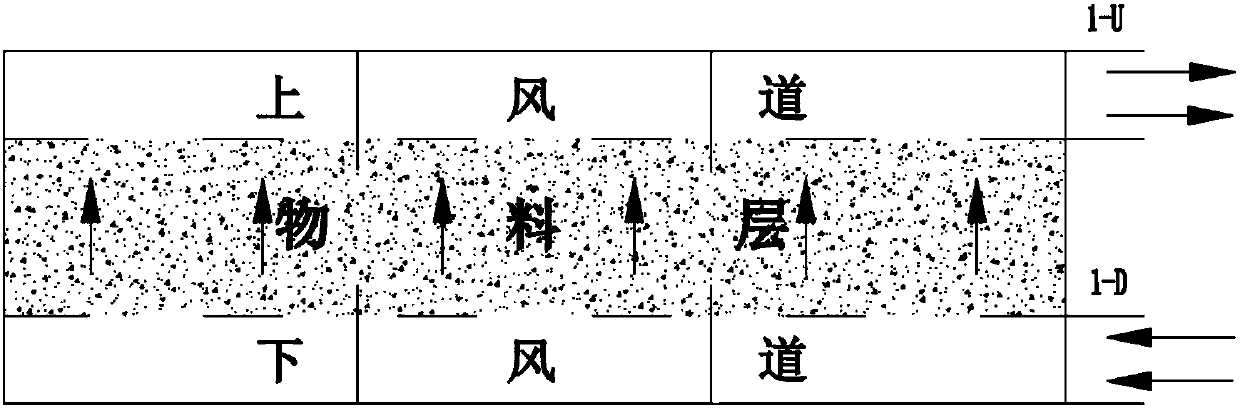

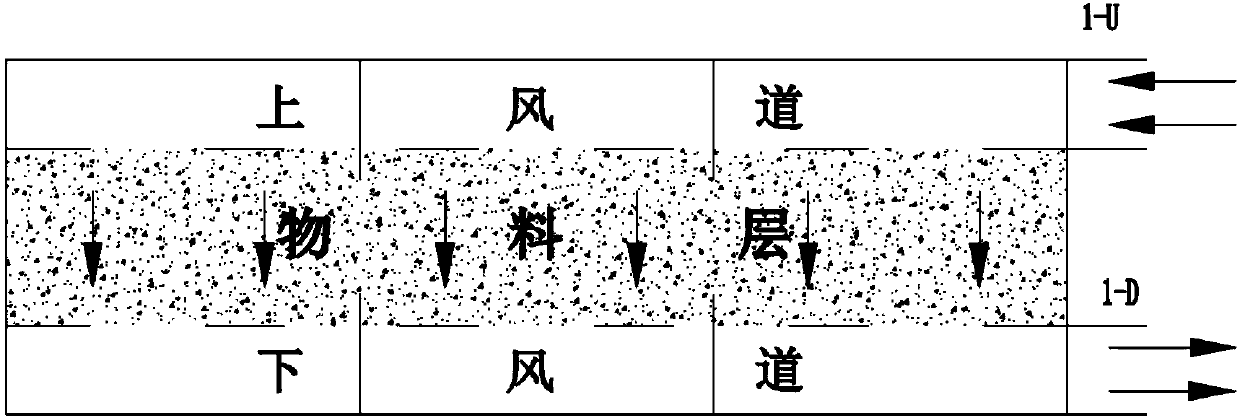

[0023] The modular reversing ventilation dryer of this embodiment is as figure 1 with Figure 7 As shown, three drying chamber modules at the front end, the middle end and the rear end are spliced and connected by fastening connectors 1-4 at the joint parts to form the entire drying tunnel 1 . This modular structure is not only very convenient for transportation and installation, but also easy to manufacture in batches. Each drying chamber module is composed of a pair of chamber cavities that are combined and connected, with an open bottom air duct 1-2 and a chamber body 1-1 with a screen mesh on the bottom through a hinge 1-3. , the bottom air duct 1-2 is a tubular structure with a rectangular cross-section, the chamber body 1-1 is a three-way structure with openings at both ends of the upper part and a screen on the bottom of the lower part, the last end of the drying channel is closed, and one end of the drying channel has channels leading to the bottom respectively. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com