Novel bolt-ball joint and preparation method thereof

A technology of bolt balls and joints, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of single large bolt ball joints and affect the safety and stability of structures, and achieve improved safety and stability, dimensional stability, and force transmission. The effect of a clear route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

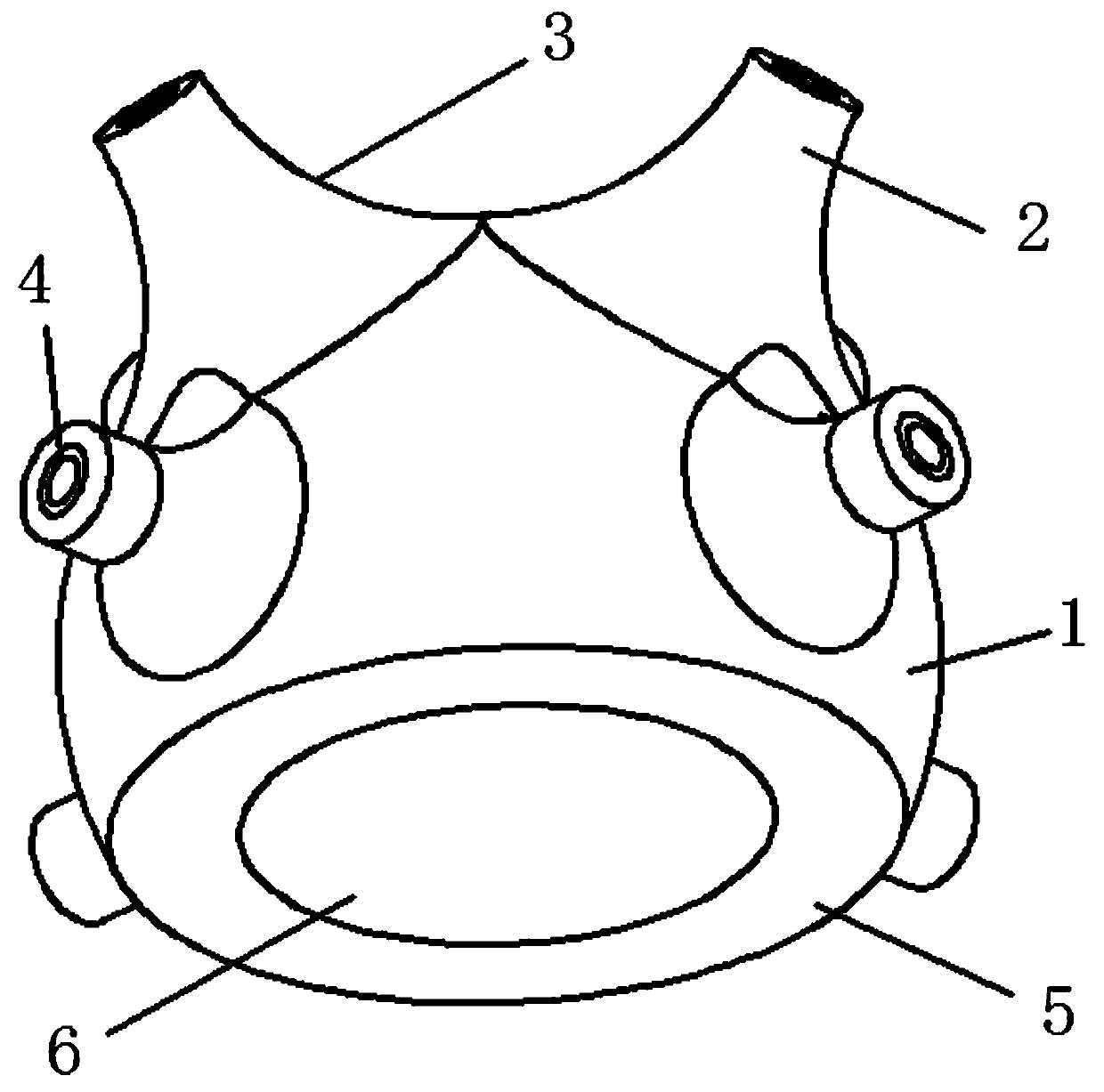

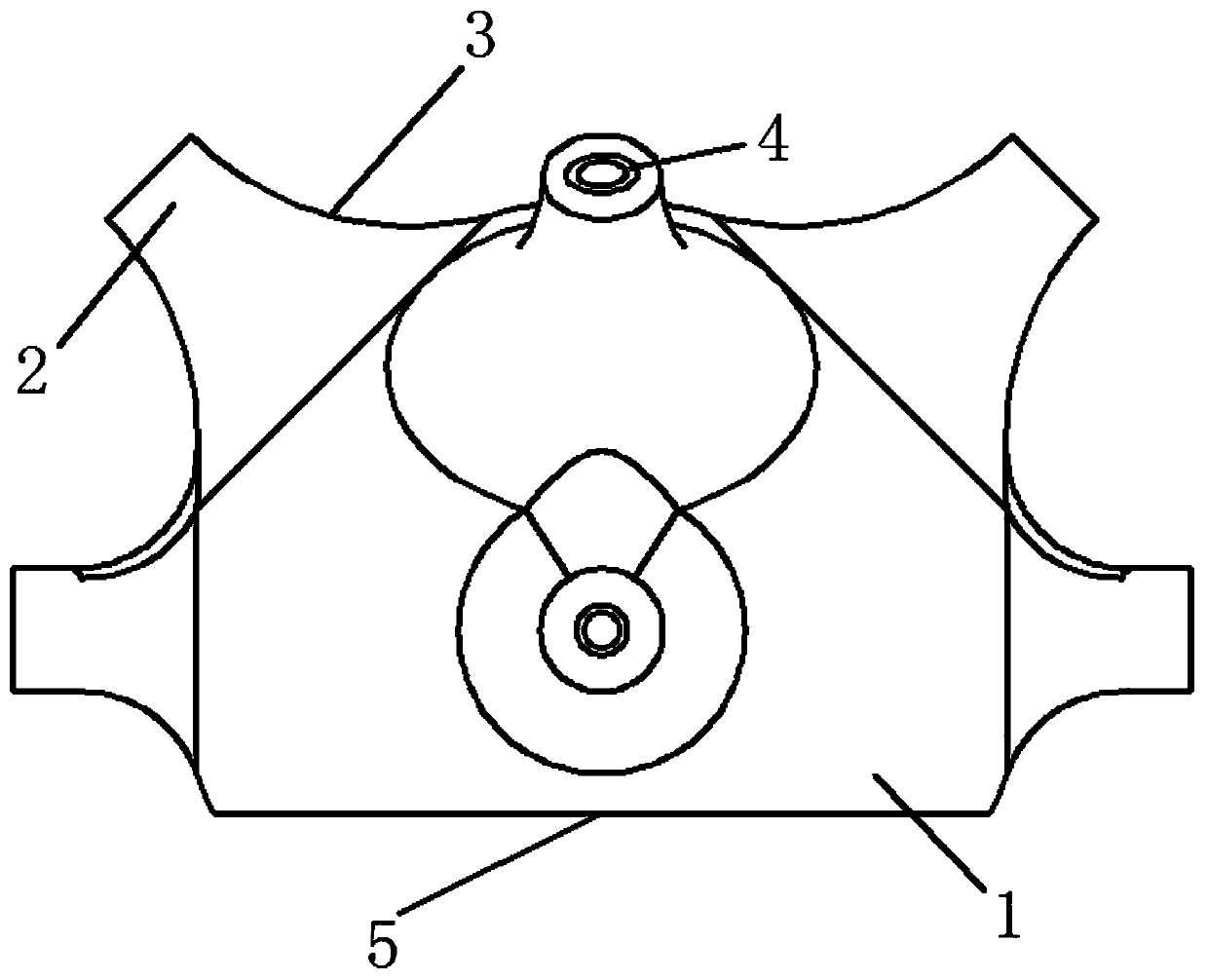

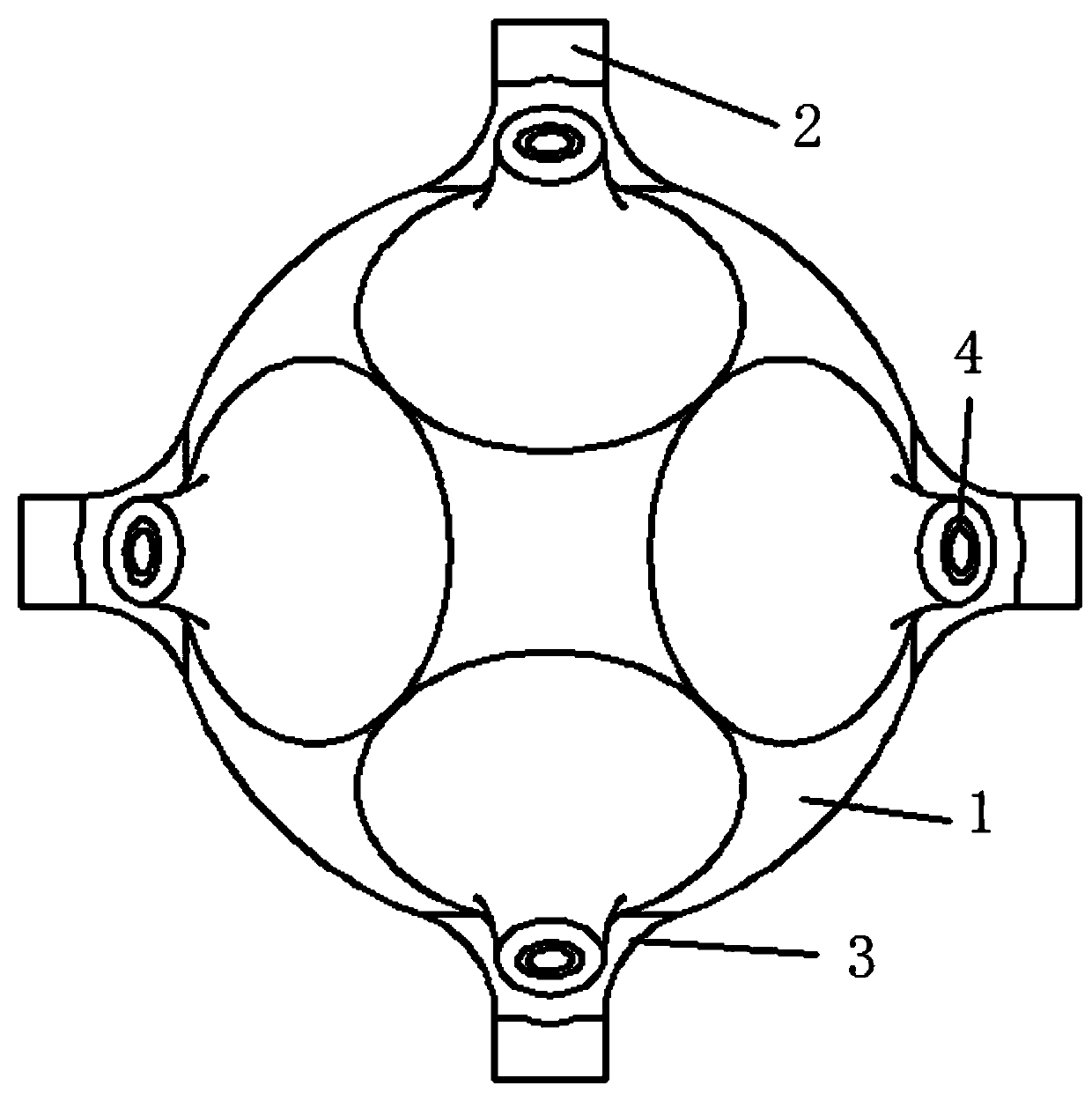

[0033] Such as Figure 1 to Figure 5 As shown, the new bolted ball joint of the present invention includes a steel ball 1 with a cavity structure inside and a branch pipe 2 arranged on the steel ball 1 for connecting and carrying steel rods. The steel ball 1 and the branch pipe 2 Integral molding, the steel ball 1 is a partially cut spherical crown, and the height of the spherical crown is greater than the radius of the steel ball, that is, the cut part of the steel ball 1 is less than half the size of the steel ball 1, and the cut surface of the steel ball is used as the The bottom surface 5 of the steel ball, the bottom surface 5 of the steel ball 1 is a plane circular structure, and the interior of the steel ball 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com