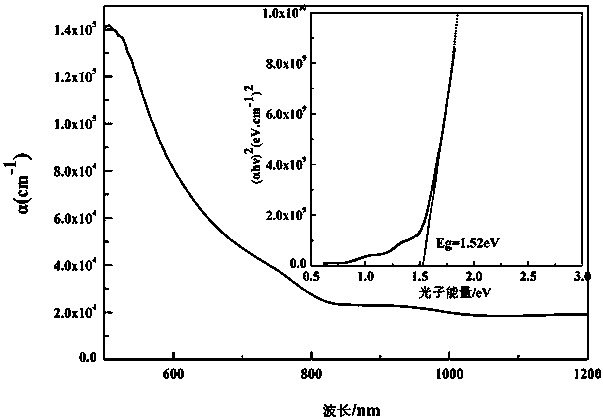

Preparation method of copper antimony sulfur film material

A thin film material, copper antimony sulfur technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of difficult control of composition, poor uniformity, many surface defects, etc., and achieve excellent crystallization, No special requirements, full effect of vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 100, depositing copper, antimony and sulfur on the pretreated soda lime glass to form a Cu—Sb—S prefabricated layer.

[0041] Specifically, the deposition method is the radio frequency magnetron sputtering method, and the Cu-Sb-S prefabricated layer is deposited by double-target reactive co-sputtering, wherein the process parameters are: argon gas flow rate 10 sccm, hydrogen sulfide gas flow rate 5 sccm, during sputtering The pressure in the sputtering chamber is 1.2Pa, the distance between the target and the soda-lime glass is 6cm, the cathode target is copper target and antimony target, and the sputtering power density of the copper target is 5W / cm 2, the sputtering power density of antimony target is 2W / cm 2 , the temperature of soda-lime glass is 200°C, the reaction time is 200min, and the rotation speed is 15r / min. It should be noted that when the Cu-Sb-S prefabricated layer is deposited by co-sputtering, the copper source can also be selected from: CuSb X T...

Embodiment 2

[0050] Step 101 , depositing copper, antimony and sulfur on the pretreated soda lime glass to form a Cu—Sb—S prefabricated layer.

[0051] Specifically, the deposition method is the radio frequency magnetron sputtering method, and the Cu-Sb-S prefabricated layer is deposited by double-target reactive co-sputtering, wherein the process parameters are: argon gas flow rate 50 sccm, hydrogen sulfide gas flow rate 25 sccm, during sputtering The pressure in the sputtering chamber is 1.5 Pa, the distance between the target and the soda-lime glass is 8 cm, and the cathode target is Cu 2 S target and Sb 2 S 3 Target, Cu 2 The sputtering power density of the S target is 80W / cm 2 , Sb 2 S 3 The sputtering power density of the target is 68W / cm 2 , the temperature of soda-lime glass is 300°C, the reaction time is 10min, and it is rotated at a speed of 150r / min.

[0052] Step 201, placing the Cu—Sb—S prefabricated layer in a sulfur-containing atmosphere for high-temperature annealing...

Embodiment 3

[0058] Step 102, depositing copper, antimony and sulfur on the pretreated soda lime glass to form a Cu—Sb—S prefabricated layer.

[0059] Specifically, DC sputtering is used for copper, radio frequency sputtering is used for antimony, and the deposition method is double-target reactive co-sputtering to deposit prefabricated layers. The process parameters are: argon gas flow rate 80 sccm, hydrogen sulfide gas flow rate 900 sccm, The pressure in the injection chamber is 12 Pa, the distance between the target and the soda-lime glass is 16cm, and the cathode target is CuSbS 2 target and CuSb alloy target, CuSbS 2 The sputtering power density of the target is 5W / cm 2 , the sputtering power density of the CuSb alloy target is 5W / cm 2 , the temperature of soda-lime glass is 300°C, the reaction time is 200min, and it is rotated at a speed of 180r / min.

[0060] Step 202, placing the Cu—Sb—S prefabricated layer in a sulfur-containing atmosphere for high temperature annealing treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com