High-frequency quenching and automatic cooling integrated machine

A high-frequency quenching and automatic cooling technology, applied in the direction of quenching device, improving energy efficiency, improving process efficiency, etc., can solve the problems of slow quenching speed, poor quenching quality and low efficiency, and achieve fast quenching speed and good quenching quality. , the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

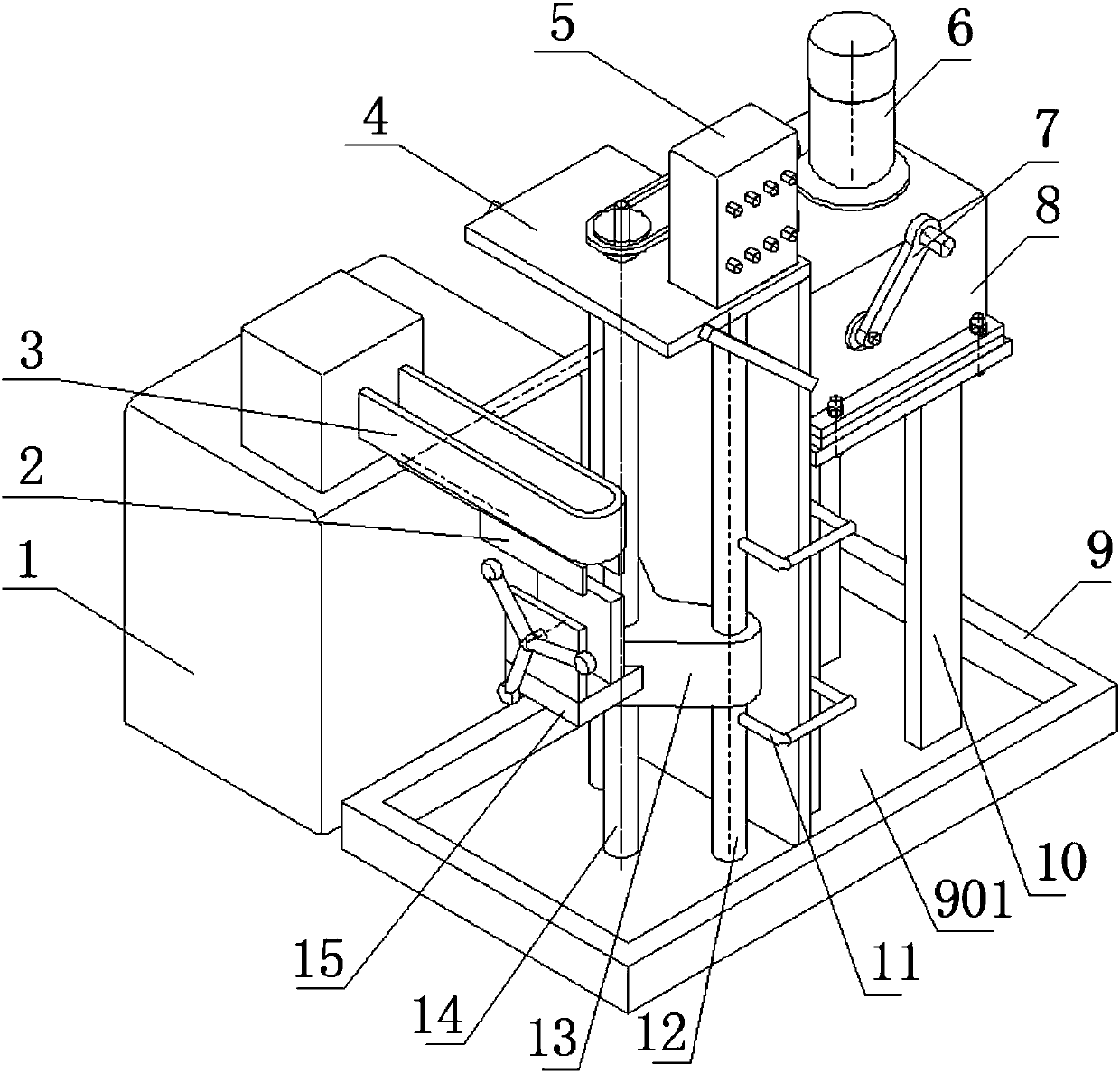

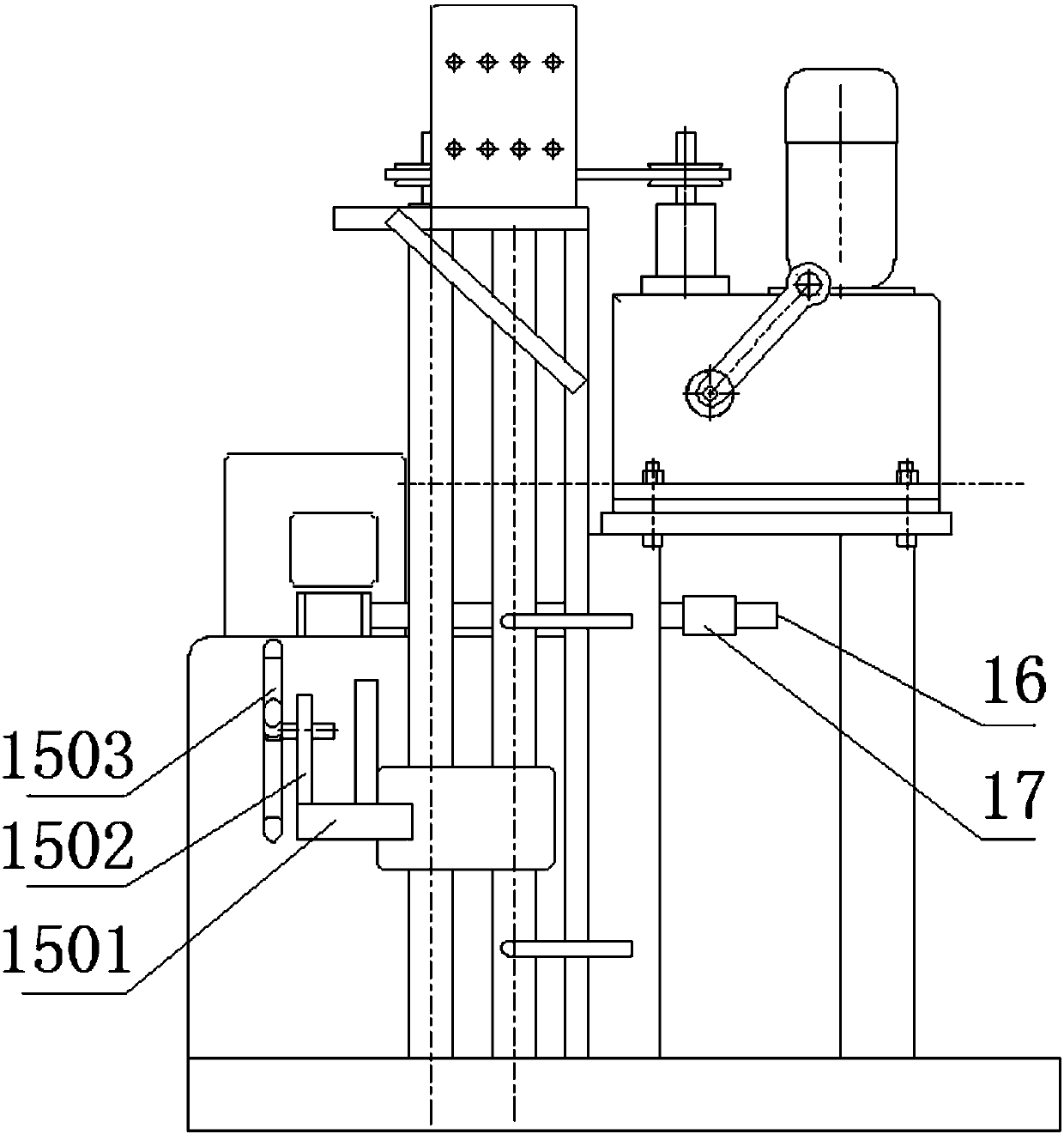

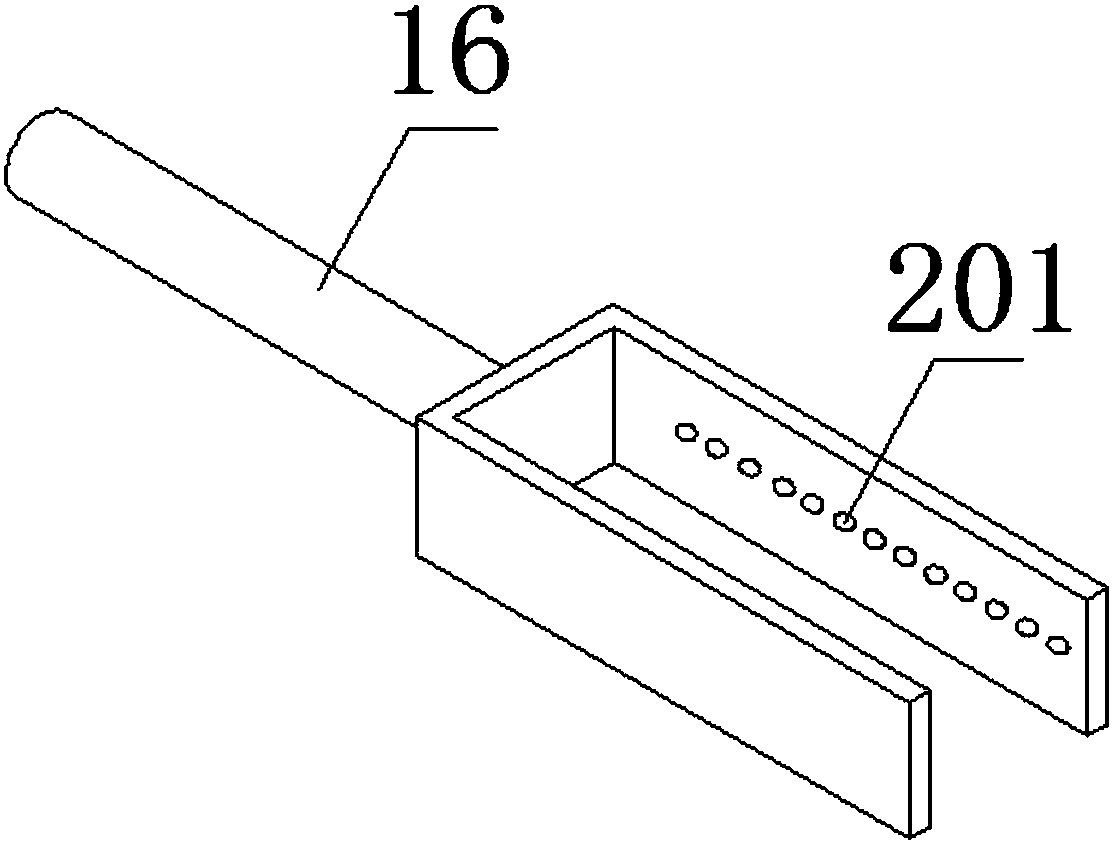

[0020] Such as Figure 1 ~ Figure 3 As shown, a high-frequency quenching automatic cooling integrated machine related to the present invention includes a high-frequency quenching machine 1, and the inductor 3 of the high-frequency quenching machine 1 is U-shaped and arranged horizontally. One side of the device 3 is provided with a base 9, and an L-shaped mounting plate 4 is arranged on the base 9, and the horizontal plate surface of the L-shaped mounting plate 4 corresponds to the side of the sensor 3.

[0021] Between the horizontal surface of the L-shaped mounting plate 4 and the base 9, two guide pillars 12 are installed side by side along the vertical direction, and the two guide pillars 12 are sleeved with sliding seats 13, and the sliding seats 13 correspond to run through two Linear bearings are respectively arranged in the through holes of the root guide posts 12 . On the L-shaped mounting plate 4, a leading screw transmission mechanism 14 is installed vertically, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com