Spiral air force combined powder conveying charging equipment

A charging equipment and screw conveying technology, applied in the field of screw pneumatic composite conveying powder charging equipment, can solve the problem of high transportation cost, and achieve the effect of speeding up loading speed, improving loading speed and saving transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

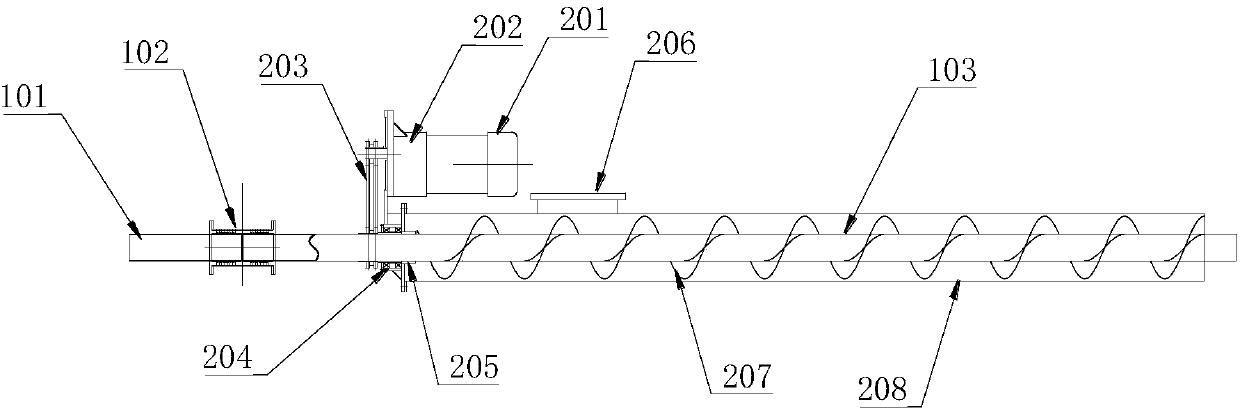

[0031] The present embodiment provides a screw pneumatic compound conveying powder charging device, which includes: a pneumatic conveying mechanism and a screw conveying mechanism. The pneumatic conveying mechanism and the screw conveying mechanism operate independently, and at the same time, the conveying pipeline of the pneumatic conveying mechanism is also used for the screw shaft of the screw conveying mechanism.

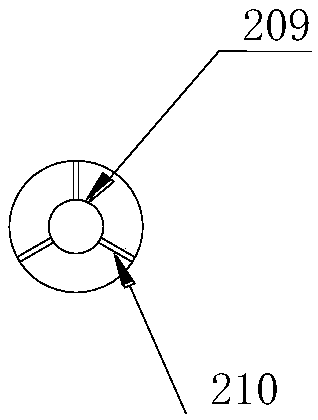

[0032] Such as Figure 1 to Figure 2 As shown, the pneumatic conveying mechanism includes a feed pipe, a rotary joint 102, and a first conveying pipeline 103. One end of the feed pipe is the first feed inlet 101, and the other end of the feed pipe is connected to the first conveying pipeline 103 through the rotary joint 102. connected.

[0033] The first material inlet 101 , the rotary joint 102 and the first conveying pipeline 103 are used for pneumatically conveying the material. When performing pneumatic conveying and charging, the powder and compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com