Field honing system with guiding rail and method for steam turbine rotor coupling nut hole

A steam turbine rotor and bolt hole technology, which is applied to honing machine tools, honing tools, metal processing equipment, etc., can solve the problems of high professional level of operators, ellipse, drum shape, bell mouth, and high labor intensity of operators. Achieve the effect of enhancing processing reliability and reducing work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with accompanying drawing:

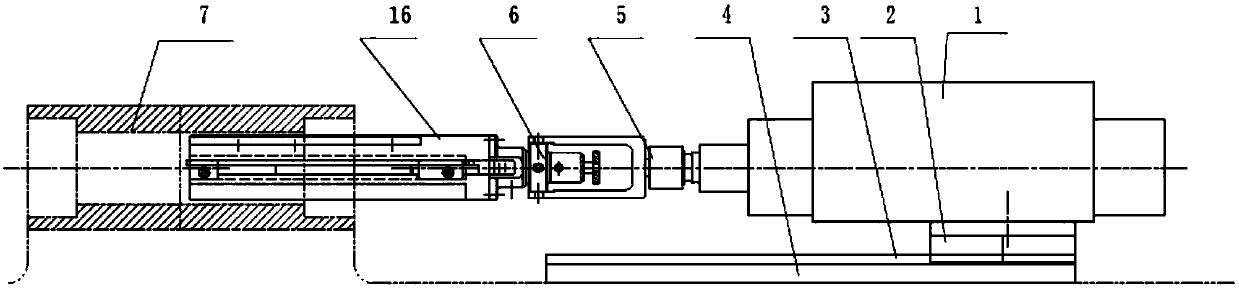

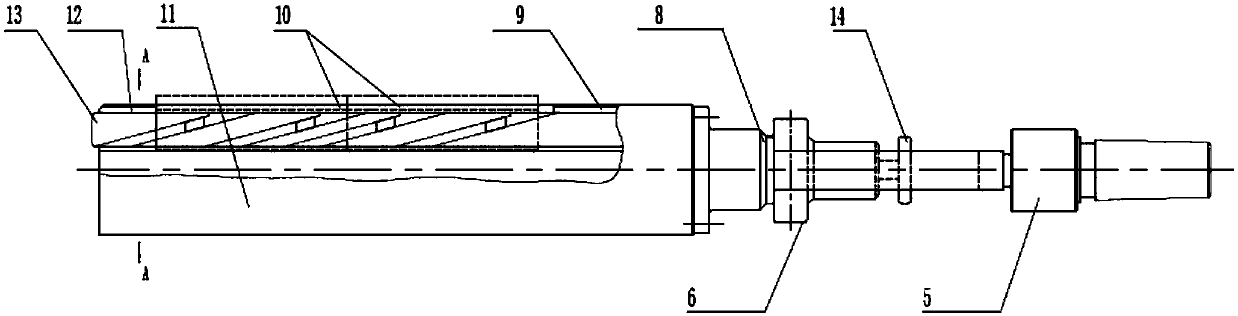

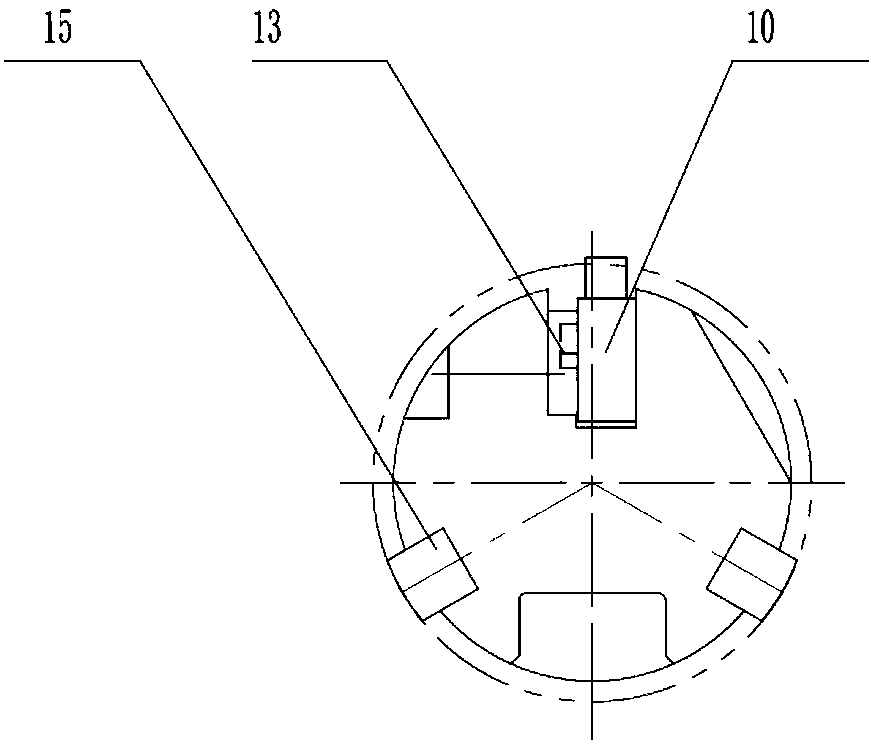

[0020] Such as Figure 1-4 As shown, this on-site honing system for steam turbine rotor wheel bolt holes with guide rail mainly includes guide rail assembly, driving tool 1 and honing tool 16. The guide rail assembly is composed of guide rail 3, slider 2 and mounting base plate 4. It can be placed at any position in the rotor and cylinder, and the hole grinding work can be carried out with a little adjustment. The driving tool 1 composed of the power unit and the driving unit is installed on the guide rail assembly, drives the honing tool 16, and feeds manually or automatically to complete the grinding work of the steam turbine rotor wheel bolt hole 7; the driving tool 1 and the honing tool The tool 16 is connected through the coupling B5 and the coupling A6, and the coupling B5 and the coupling A6 adopt a universal or floating connection structure, which reduces the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com