Follow-up profile and follow-up support for wheelchair and follow-up mechanism

A follow-up mechanism and wheelchair vehicle technology, applied in the field of wheelchair vehicles, can solve the problems of heavy weight and large volume, and achieve the effects of fast electrical connection and disassembly, reduced machining amount, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

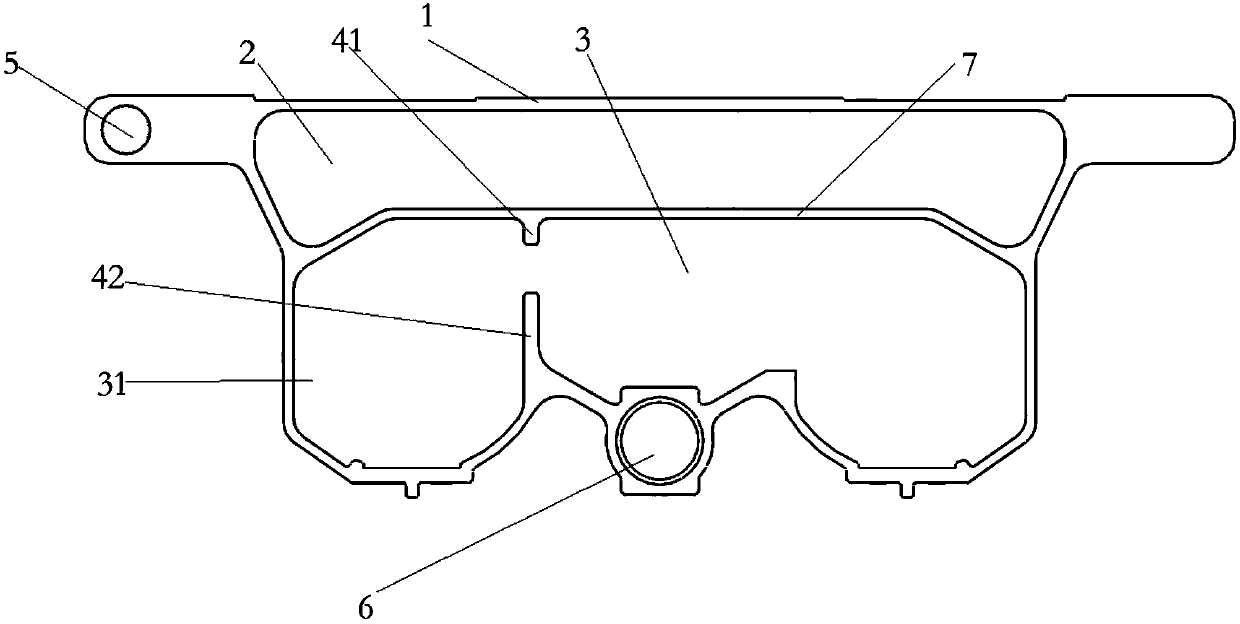

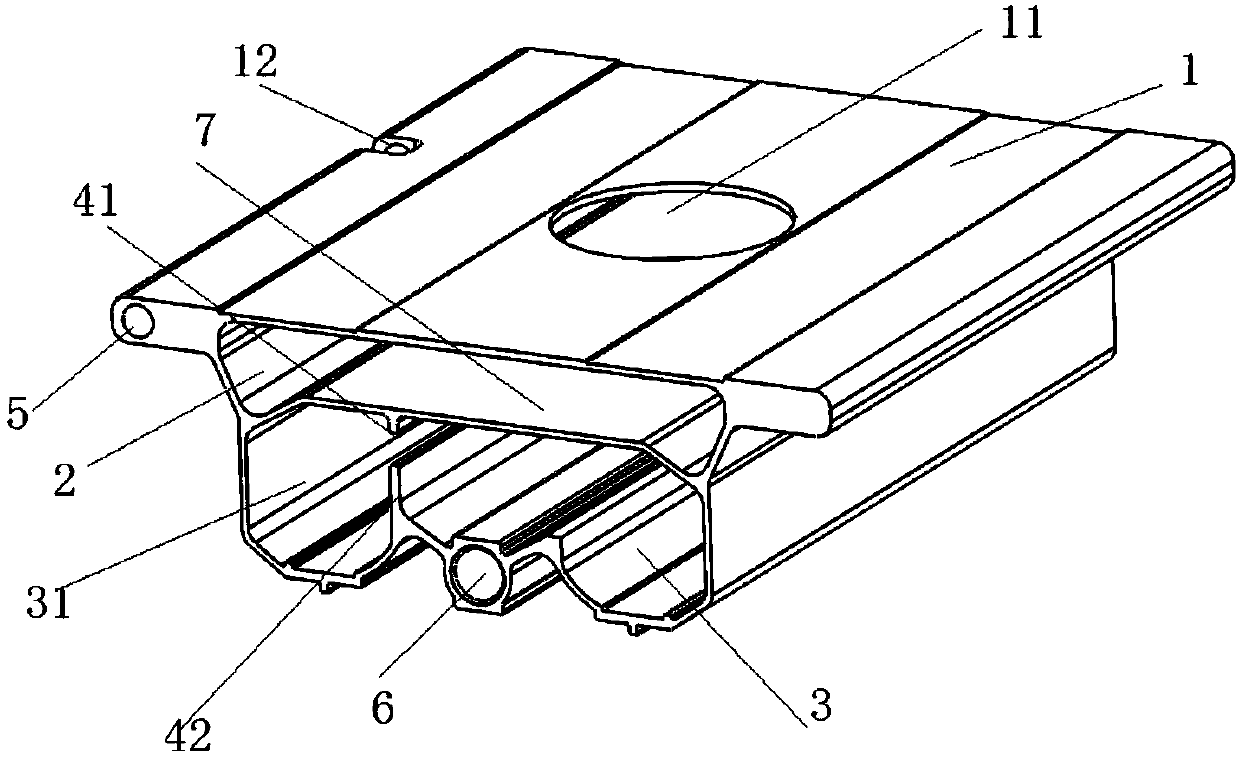

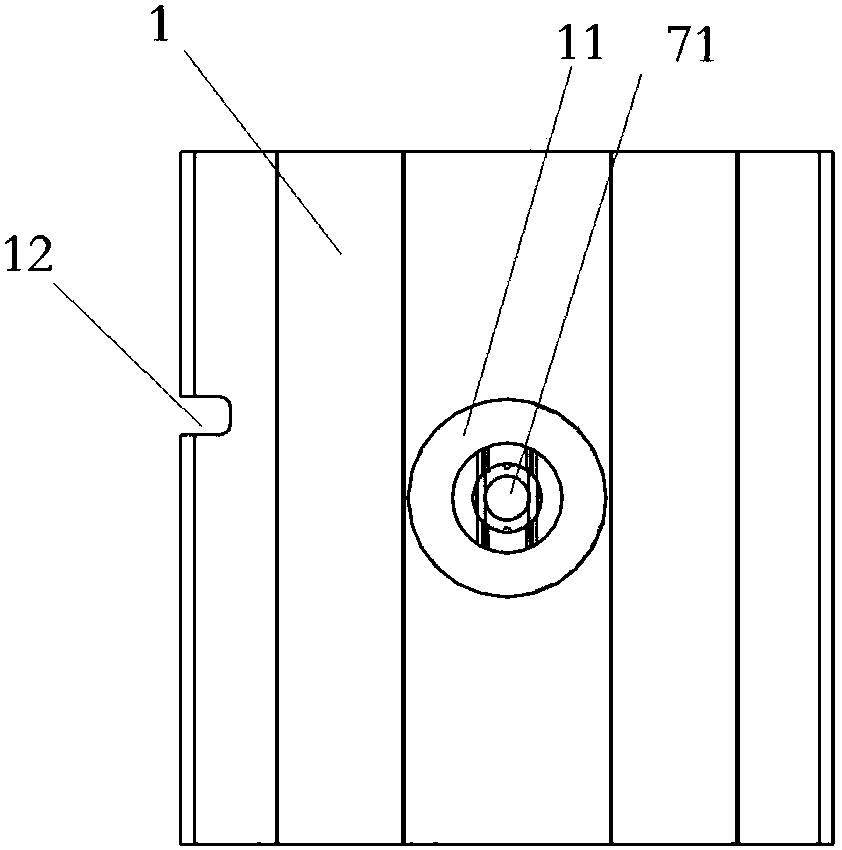

[0054] Such as figure 1 As shown, the follower profile of the present invention includes an upper end plate 1 arranged along the length direction of the profile, an accommodating cavity arranged below the upper end plate 1 , a positioning rib plate 7 , a guide rib, a connecting shaft hole 5 and a swinging shaft hole 6 . The positioning rib plate 7 has at least a positioning plane parallel to the upper end plate 1, and divides the interior of the accommodation cavity into an upper accommodation cavity 2 and a lower accommodation cavity 3 distributed up and down. At least one group of guide ribs is arranged on one side of the lower accommodation cavity 3, separating A side housing cavity 31 is used for placing the motor. A group of guide ribs is composed of upper guide ribs 41 and lower guide ribs 42 arranged side by side and spaced from each other, and extend from the lower end surface of the positioning rib plate 7 and the corresponding cavity wall surface of the lower accommo...

Embodiment 2

[0060] Such as Figure 6 As shown, the follower profile of the present invention includes an upper end plate 1 arranged along the length direction of the profile, an accommodation cavity arranged below the upper end plate 1, a positioning rib plate 7, a guide rib, a connecting shaft hole 5, a forming hole 22 and a swing shaft hole 6 . The positioning rib plate 7 has at least a positioning plane parallel to the upper end plate 1, and divides the interior of the accommodation chamber into an upper accommodation chamber 2 and a lower accommodation chamber 3 distributed up and down. Two groups of guide ribs 4 are arranged on both sides of the lower accommodation chamber 3, separating the There are two side accommodation cavities 31 and the middle cavity, and one of the side accommodation cavities 31 is used to place the motor. The middle cavity of the lower accommodation cavity 31 is provided with a horizontal reinforcing rib plate 35 along the length direction, which divides the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com