Novel graphene heating material

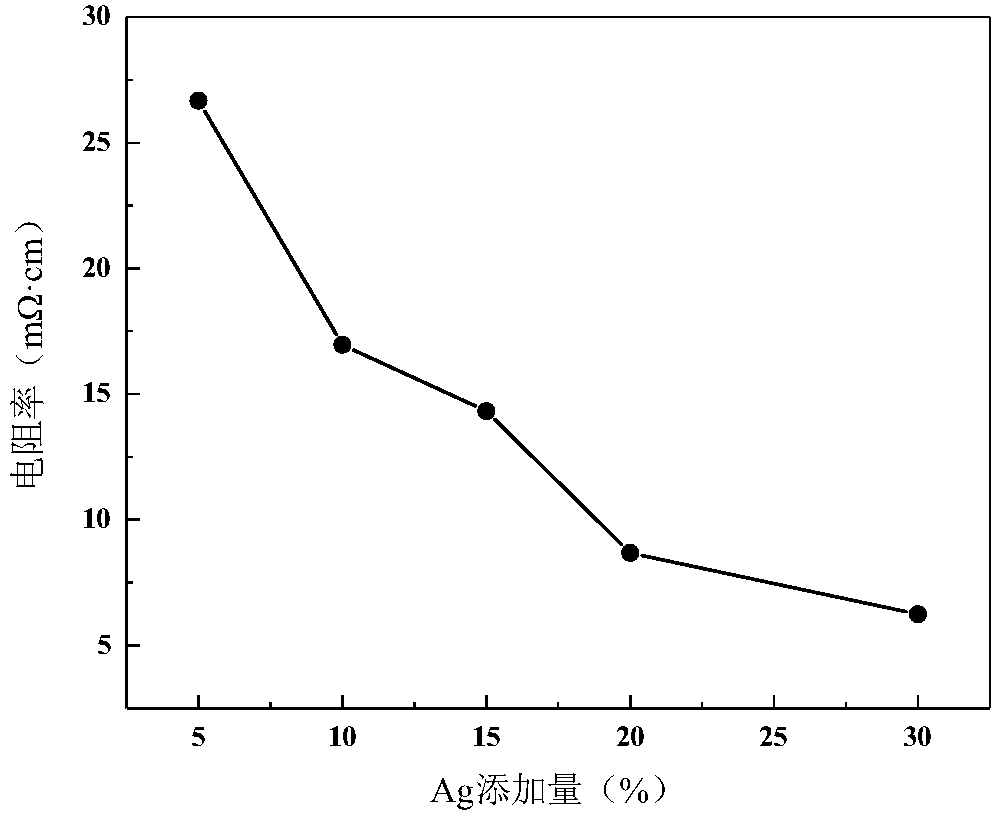

A technology for heating materials and graphene, which is applied in the field of materials, can solve the problems of inferior electrical properties of graphene, unsatisfactory electrical properties, and large longitudinal resistivity, and achieve the effects of low cost, short preparation cycle, and reduced resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

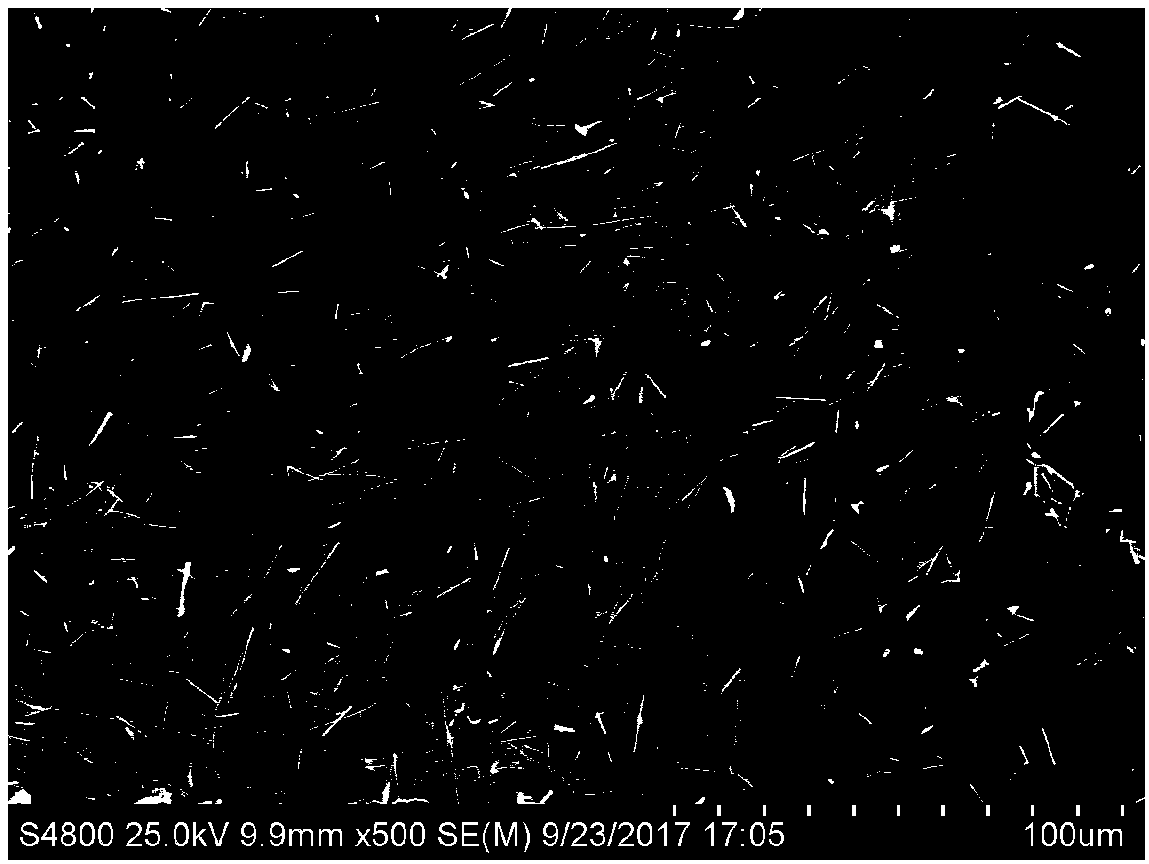

Image

Examples

Embodiment 1

[0043] Step (1). With 9.7mg FeCl 3 Dissolve in 100mL EG to prepare 6mmol / L FeCl 3 solution.

[0044] Step (2). 0.25g AgNO 3 Dissolve in 1.25g EG and mix well.

[0045] Step (3). Dissolve 0.2g of PVP in 1.25g of EG and mix well.

[0046] Step (4). Get 0.34g 6mmol / L FeCl 3 solution.

[0047] Step (5). Add step (2), step (3) and step (4) to the Erlenmeyer flask in sequence, mix well, put the Erlenmeyer flask into an oven at 110° C. for 12 hours.

[0048] Step (6). Take out the Erlenmeyer flask, let it stand, and remove the waste liquid in the upper layer.

[0049] Step (7). The silver nanowire precipitate obtained in step (6) is washed with deionized water, left to stand, and the upper layer of waste liquid is removed.

[0050] Step (8). The silver nanowire precipitate obtained in step (7) is washed with deionized water, left to stand, and the upper layer of waste liquid is removed.

[0051] Step (9). Wash the silver nanowire precipitate obtained in step (8) with absolute...

Embodiment 2

[0061] Step (1). With 9.7mg FeCl 3 Dissolve in 100mL EG to prepare 6mmol / L FeCl 3 solution.

[0062] Step (2). 0.25g AgNO 3 Dissolve in 1.25g EG and mix well.

[0063] Step (3). Dissolve 0.2g of PVP in 1.25g of EG and mix well.

[0064] Step (4). Get 0.34g 6mmol / L FeCl 3 solution.

[0065] Step (5). Add step (2), step (3) and step (4) to the Erlenmeyer flask in sequence, mix well, put the Erlenmeyer flask into an oven at 110° C. for 12 hours.

[0066] Step (6). Take out the Erlenmeyer flask, let it stand, and remove the waste liquid in the upper layer.

[0067] Step (7). The silver nanowire precipitate obtained in step (6) is washed with deionized water, left to stand, and the upper layer of waste liquid is removed.

[0068] Step (8). The silver nanowire precipitate obtained in step (7) is washed with deionized water, left to stand, and the upper layer of waste liquid is removed.

[0069] Step (9). Wash the silver nanowire precipitate obtained in step (8) with absolute...

Embodiment 3

[0079] Step (1). With 9.7mg FeCl 3 Dissolve in 100mL EG to prepare 6mmol / L FeCl 3 solution.

[0080] Step (2). 0.25g AgNO 3 Dissolve in 1.25g EG and mix well.

[0081] Step (3). Dissolve 0.2g of PVP in 1.25g of EG and mix well.

[0082] Step (4). Get 0.34g 6mmol / L FeCl 3 solution.

[0083] Step (5). Add step (2), step (3) and step (4) to the Erlenmeyer flask in sequence, mix well, put the Erlenmeyer flask into an oven at 110° C. for 12 hours.

[0084] Step (6). Take out the Erlenmeyer flask, let it stand, and remove the waste liquid in the upper layer.

[0085] Step (7). The silver nanowire precipitate obtained in step (6) is washed with deionized water, left to stand, and the upper layer of waste liquid is removed.

[0086] Step (8). The silver nanowire precipitate obtained in step (7) is washed with deionized water, left to stand, and the upper layer of waste liquid is removed.

[0087] Step (9). Wash the silver nanowire precipitate obtained in step (8) with absolute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com