Method for preparing nano cellulose fibril

A nanocellulose and fibril technology, applied in fiber raw material processing, textile and papermaking, etc., can solve the problems of high energy consumption, low product yield, and high energy consumption of nanocellulose, achieve efficient removal, and inhibit excessive hydrolysis. , the effect of preserving the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing nano cellulose filaments. The preparation method includes the following steps:

[0029] S1, provide the biomass material, and process the biomass material with NaOH solution to obtain the processed biomass material;

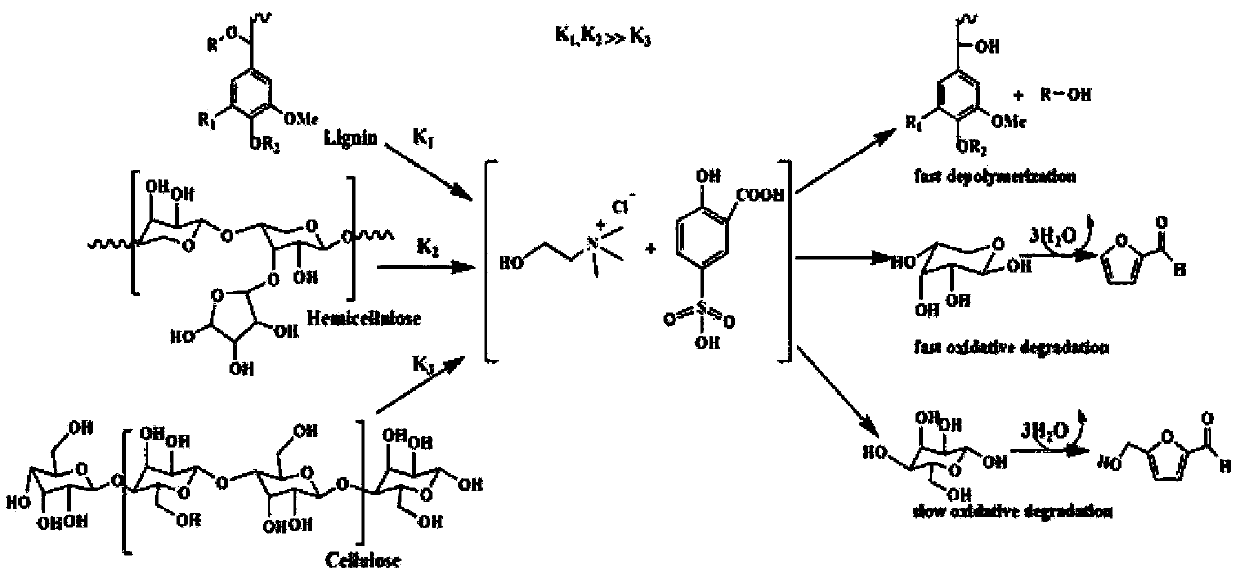

[0030] S2, mix choline chloride and sulfosalicylic acid in a molar ratio of 1:1 to 4:1, and heat to 50°C to 80°C to obtain an acidic eutectic salt solution; S3, combine the obtained in step 1) The treated biomass material is added to the acidic eutectic salt solution obtained in step 2), and the temperature is increased to 80°C to 120°C, and the mixture is kept and stirred for 4 hours to 6 hours to obtain a mixture;

[0031] S4, filtering the mixture obtained in step 3) to obtain nanocellulose fibrils.

[0032] In step S1, the biomass material includes wood, bamboo, bark, etc. Before the biomass material is treated with the NaOH solution, the biomass material is crushed into particles. Specifically, the biomass mate...

Embodiment 1

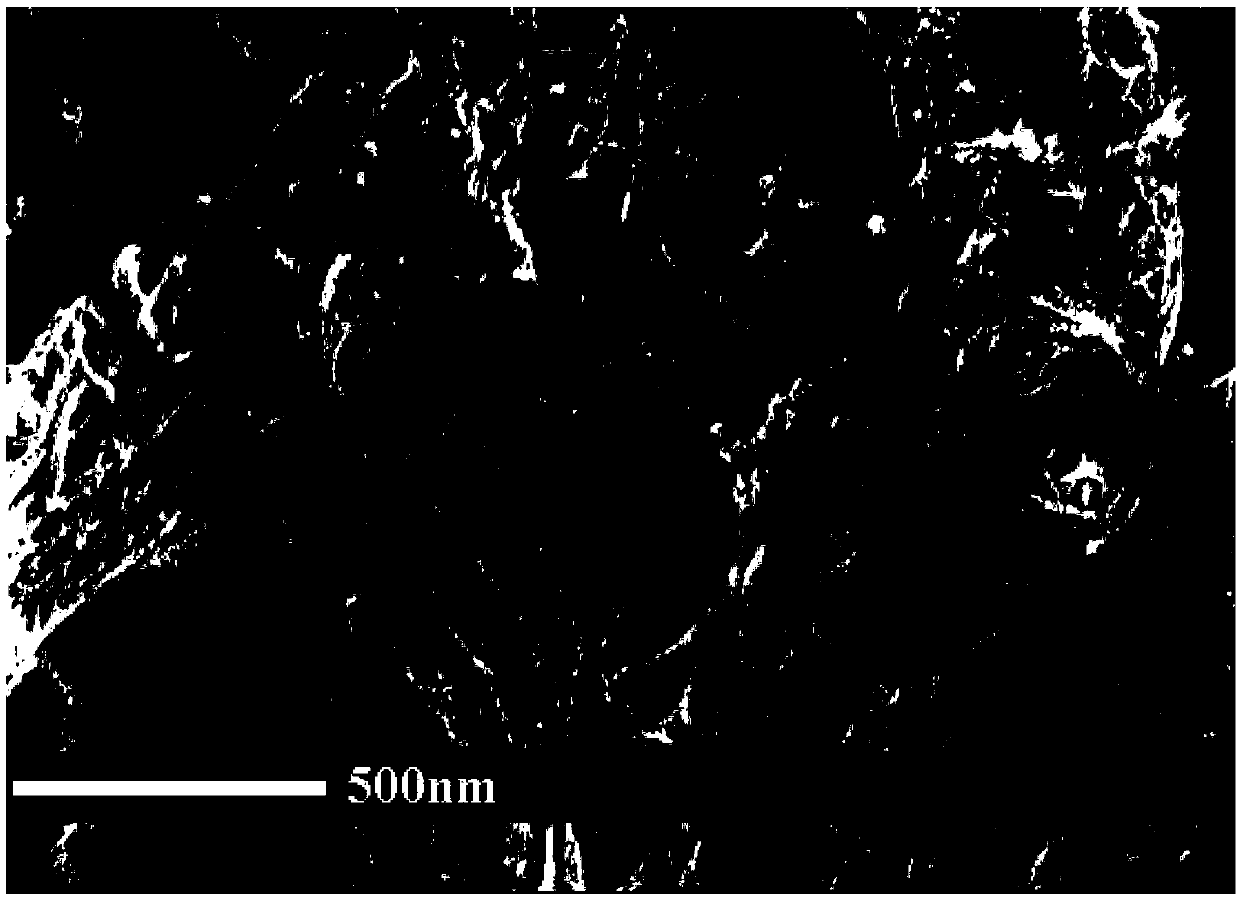

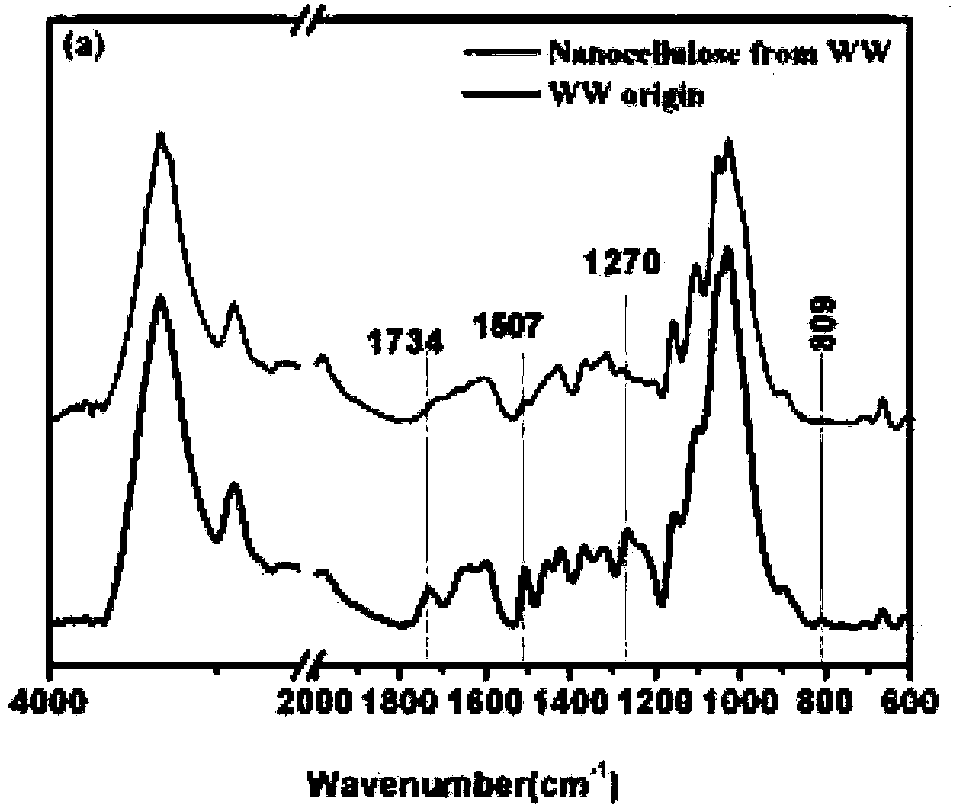

[0041] Extracting nano-cellulose from cork chips includes the following steps:

[0042] 1) Put it into a grinder and grind into particles, put it in NaOH solution and boil, the mass fraction of NaOH in NaOH solution is 3%, the ratio of biomass material to NaOH solution is 10g: 100mL, and wash with hydrochloric acid or phosphoric acid. Adjust the pH of the biomass material to neutral and dry it in vacuum for use;

[0043] 2) Mix choline chloride and sulfosalicylic acid at a molar ratio of 1:1, stir magnetically, and heat to 65°C to obtain an acidic eutectic salt solution;

[0044] 3) Add the treated biomass material obtained in step 1) to the acidic eutectic salt solution obtained in step 2), and raise the temperature to 80° C., heat and stir for 6 hours to obtain a mixture, and process in step 3) The ratio of the latter biomass material to the acidic eutectic salt solution is 15g: 100mL;

[0045] 4) Filter the mixture obtained in step 3) to obtain nanocellulose fibrils.

[0046] In st...

Embodiment 2

[0051] Extracting nano-cellulose from bamboo chips includes the following steps:

[0052] 1) Put it into a grinder to grind into particles, put it in NaOH solution and boil it, the mass fraction of NaOH in NaOH solution is 10%, the ratio of biomass material to NaOH solution is 1g: 100mL, and wash with hydrochloric acid or phosphoric acid. Adjust the pH of the biomass material to neutral and dry it in vacuum for use;

[0053] 2) Mix choline chloride and sulfosalicylic acid in a 4:1 molar ratio, stir magnetically, and heat to 65°C to obtain an acidic eutectic salt solution;

[0054] 3) Add the treated biomass material obtained in step 1) to the acidic eutectic salt solution obtained in step 2), and raise the temperature to 100° C., heat and stir for 5 hours to obtain a mixture, and process in step 3) The ratio of the latter biomass material to the acidic eutectic salt solution is 5g: 100mL;

[0055] 4) Filter the mixture obtained in step 3) to obtain nanocellulose fibrils.

[0056] In s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com