Waterborne glass baking varnish

A glass baking paint, water-based technology, used in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of low hardness and poor wear resistance, and achieve the effect of high hardness, excellent wear resistance and high gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

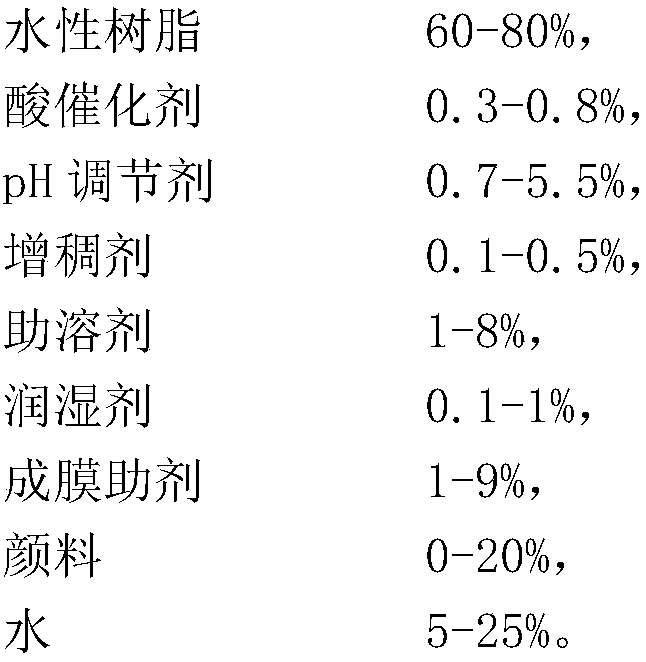

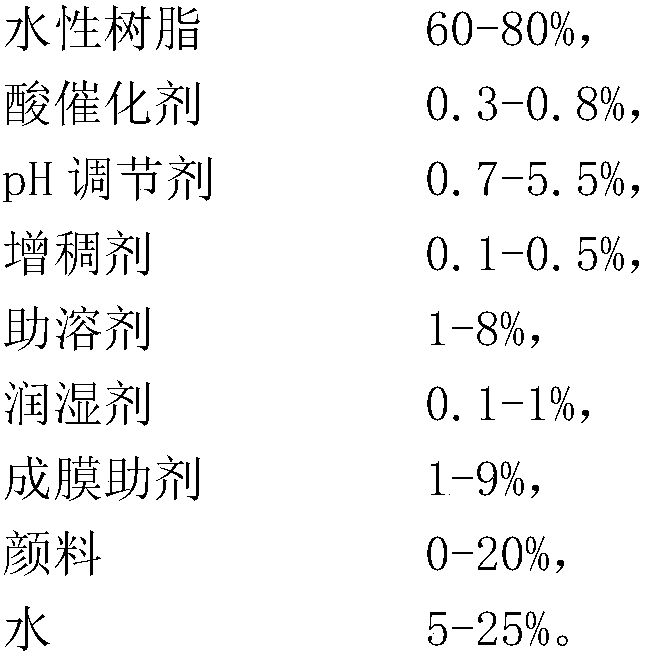

Method used

Image

Examples

Embodiment 1

[0018] A water-based glass baking varnish, by weight percentage, comprises the following components: 80% of water-based resin, 0.8% of acid catalyst, 5% of pH regulator, 0.1% of thickener, 1% of cosolvent, 0.1% of wetting agent, and Membrane aid 2%, pigment 0, water 11%.

[0019] The water-based resin is a 1:1 mixture of hydroxyl acrylic resin and epoxy acrylic resin, the acid catalyst is p-toluenesulfonic acid, the pH regulator is 2-amino-2-methyl-1-propanol, and the thickener is polyurethane and The polyacrylamide is mixed at a ratio of 1:1, the cosolvent is ethylene glycol butyl ether, the wetting agent is a silicone-based wetting agent, and the film-forming aid is propylene glycol butyl ether.

Embodiment 2

[0021] A water-based glass baking varnish comprises the following components by weight percentage: 75% of water-based resin, 0.7% of acid catalyst, 3.2% of pH regulator, 0.3% of thickener, 2.6% of cosolvent, 0.5% of wetting agent, and 4% film aid, 10% pigment, 3.7% water.

[0022] The water-based resin is a 1:1 mixture of epoxy acrylic resin and melamine resin, the acid catalyst is dodecylbenzenesulfonic acid, the pH regulator is N-methylethanolamine, and the thickener is polyacrylamide and polyvinyl alcohol 1:1 Mixing, the co-solvent is a 1:1 mixture of ethylene glycol butyl ether and diethylene glycol butyl ether, the wetting agent is an acetylene glycol wetting agent, and the film-forming aid is propylene glycol methyl ether acetate.

Embodiment 3

[0024] A water-based glass baking varnish, by weight percentage, comprises the following components: 70% of water-based resin, 0.5% of acid catalyst, 4.1% of pH regulator, 0.2% of thickener, 1.5% of cosolvent, 0.6% of wetting agent, and Film aid 1.5%, pigment 5%, water 16.6%.

[0025] The water-based resin is a 1:1 mixture of melamine resin and polyamide resin, the acid catalyst is dinonylnaphthalenesulfonic acid, the pH regulator is triethanolamine, and the thickener is a 1:1:1 mixture of polyacrylamide, polyvinyl alcohol and polyacrylic acid , the cosolvent is propylene glycol dibutyl ether, the wetting agent is a silicone wetting agent, and the film-forming aid is propylene glycol butyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com