A mill for activated carbon production

A technology of activated carbon production and pulverizer, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of unqualified activated carbon powder, the degree of grinding does not meet the fine requirements, affecting the efficiency and quality of activated carbon, etc. To achieve the effect of guaranteed dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

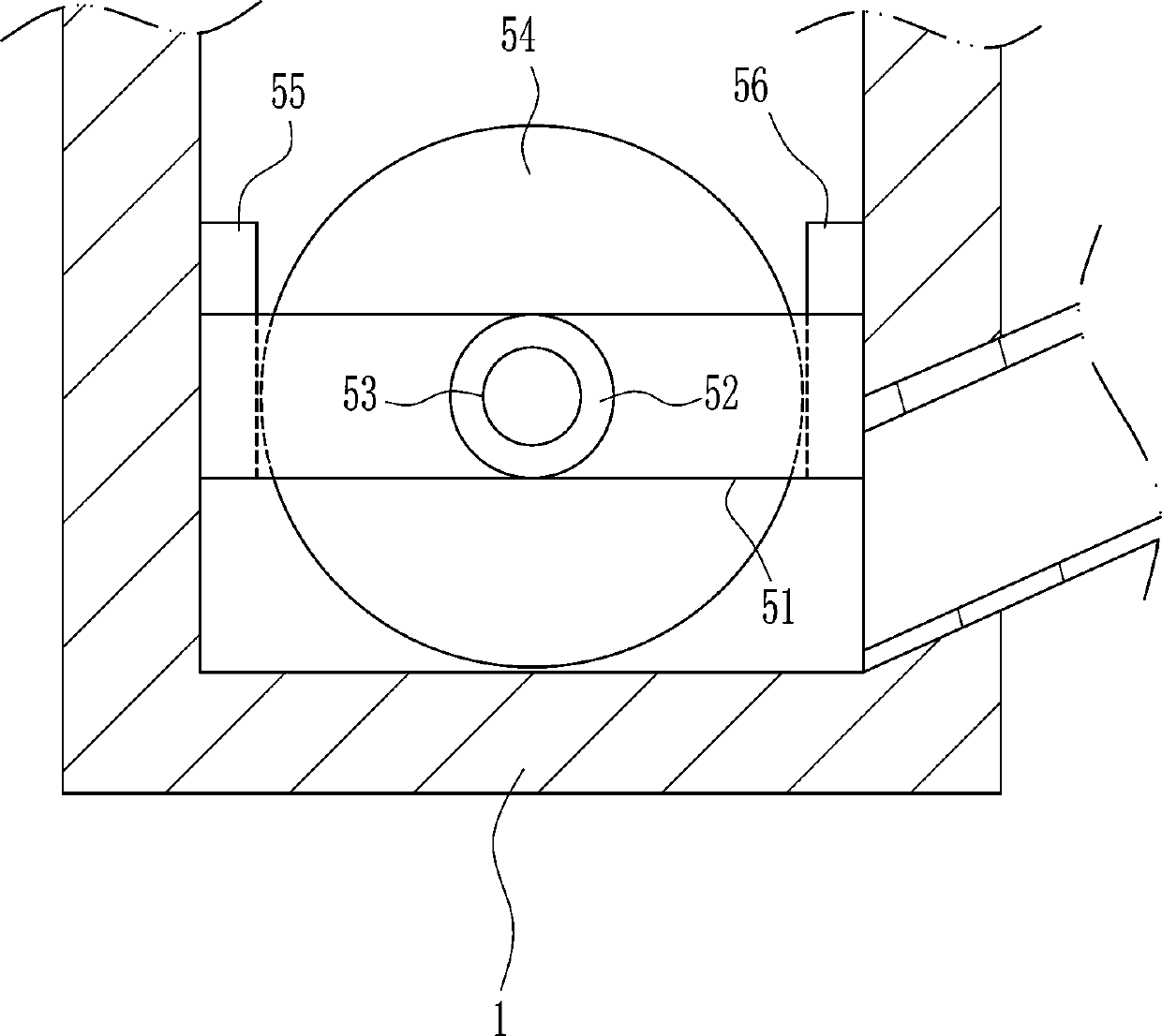

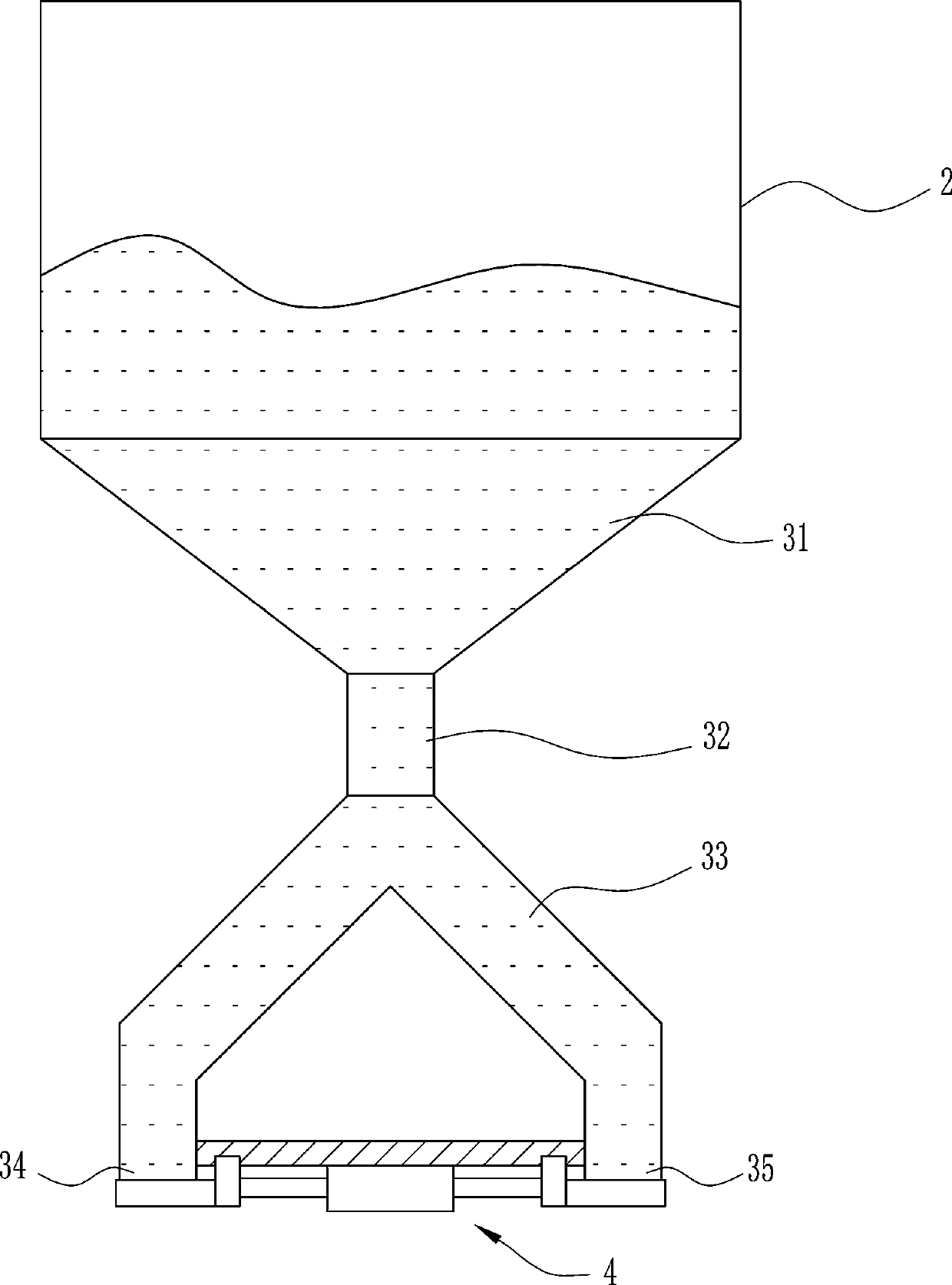

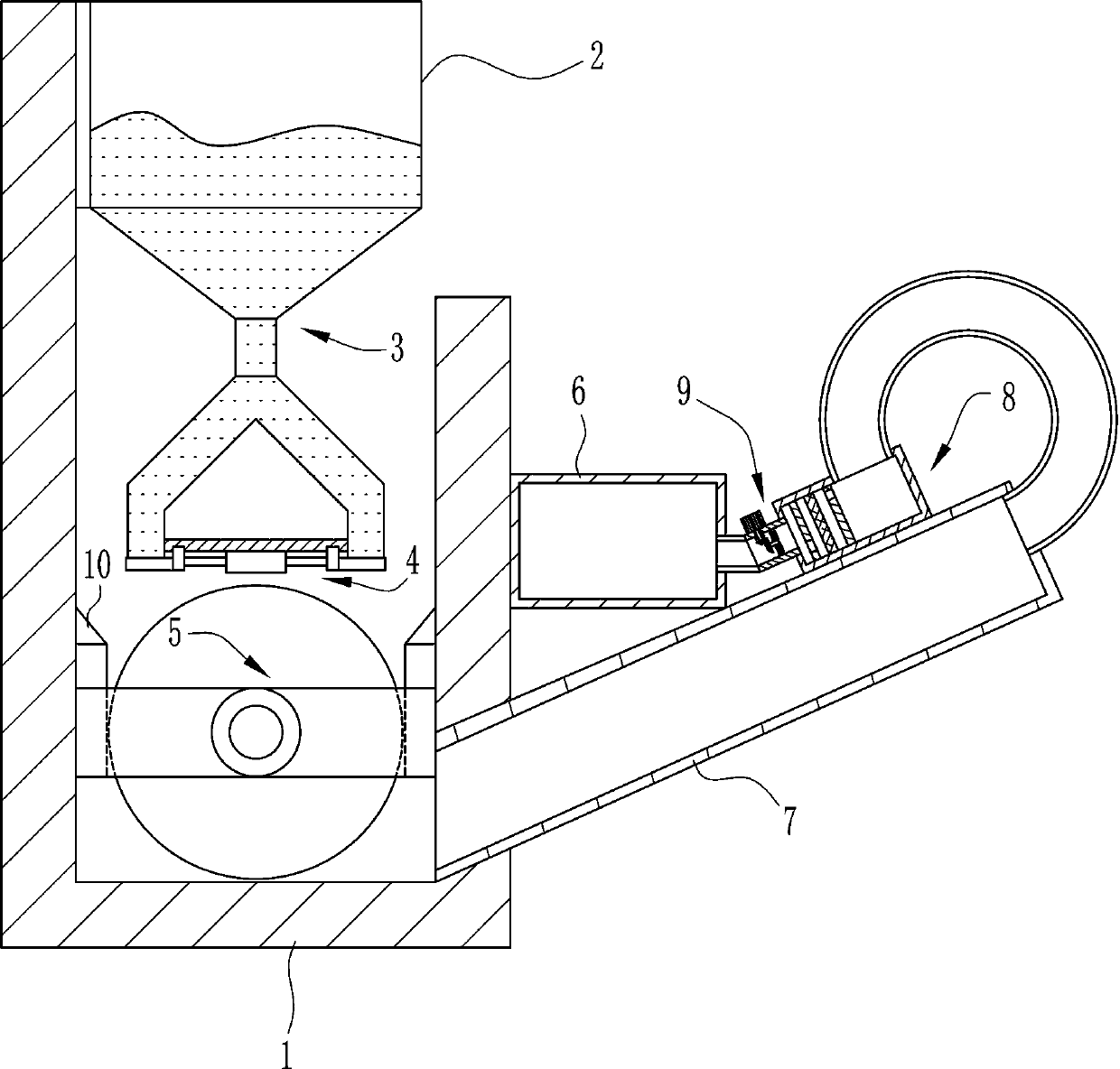

[0037] A mill for activated carbon production, such as Figure 1-8 As shown, it includes a crushing tank body 1, a storage box 2, a feeding pipe fitting 3, a feeding part 4, a crushing part 5, a collection box 6, an inclined pipe 7, a filter part 8 and an exhaust part 9; the storage box 2 is fixedly connected to the inner side wall of the crushing tank 1, the feeding pipe part 3 is fixedly connected to the bottom of the storage box 2, the feeding part 4 is fixedly connected to the feeding pipe part 3; the crushing part 5 is fixedly connected to the inside of the crushing tank 1 wall, and is located directly below the blanking part 4; the inclined pipe 7 is fixed on the inner side wall of the crushing tank 1, and is located below the crushing part 5; the collection box 6 is fixed on the outer side wall of the crushing tank 1, and the ventilation part It is fixedly connected to the collection box 6; one end of the filter part 8 is fixedly connected to the exhaust part 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com