Large-scale processing integration method for atomic devices

An integrated method and large-scale technology, applied in the field of microelectronics technology, can solve the problems of inability to meet the processing and integration requirements of a large number of atomic devices, and the low efficiency of single-atom manipulation, so as to achieve efficient processing and integration, and meet a large number of easy-to-implement requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

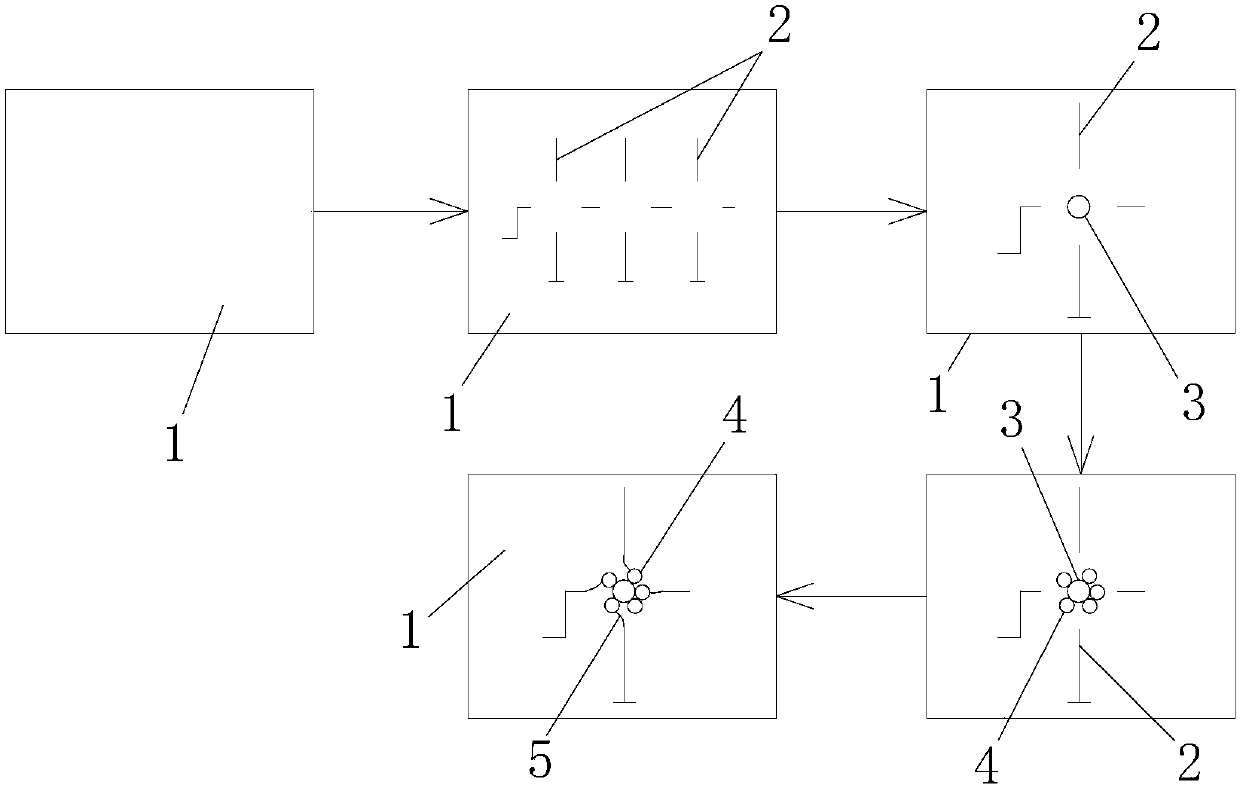

[0034] Embodiment 1, with reference to figure 1 , the large-scale processing and integration method of atomic-level devices is based on a typical processing and operation scheme combining top-down and bottom-up, the specific process is as follows,

[0035] 1) Process a batch of peripheral circuits 2 on the substrate of the substrate 1 by using photolithography and electron beam lithography;

[0036] 2) Use the method of light field manipulation to control the distribution of the potential field in space, and settle a seed 3 in the designated micro-area;

[0037] 3), according to the selectivity of atoms and molecules, grow the device core 4 around the seed 3;

[0038] 4) According to the selectivity of atomic molecules, the device core 4 adsorbs the black atomic chain 5 to realize the connection with the peripheral circuit 2 to form a large-scale atomic-level device.

Embodiment 2

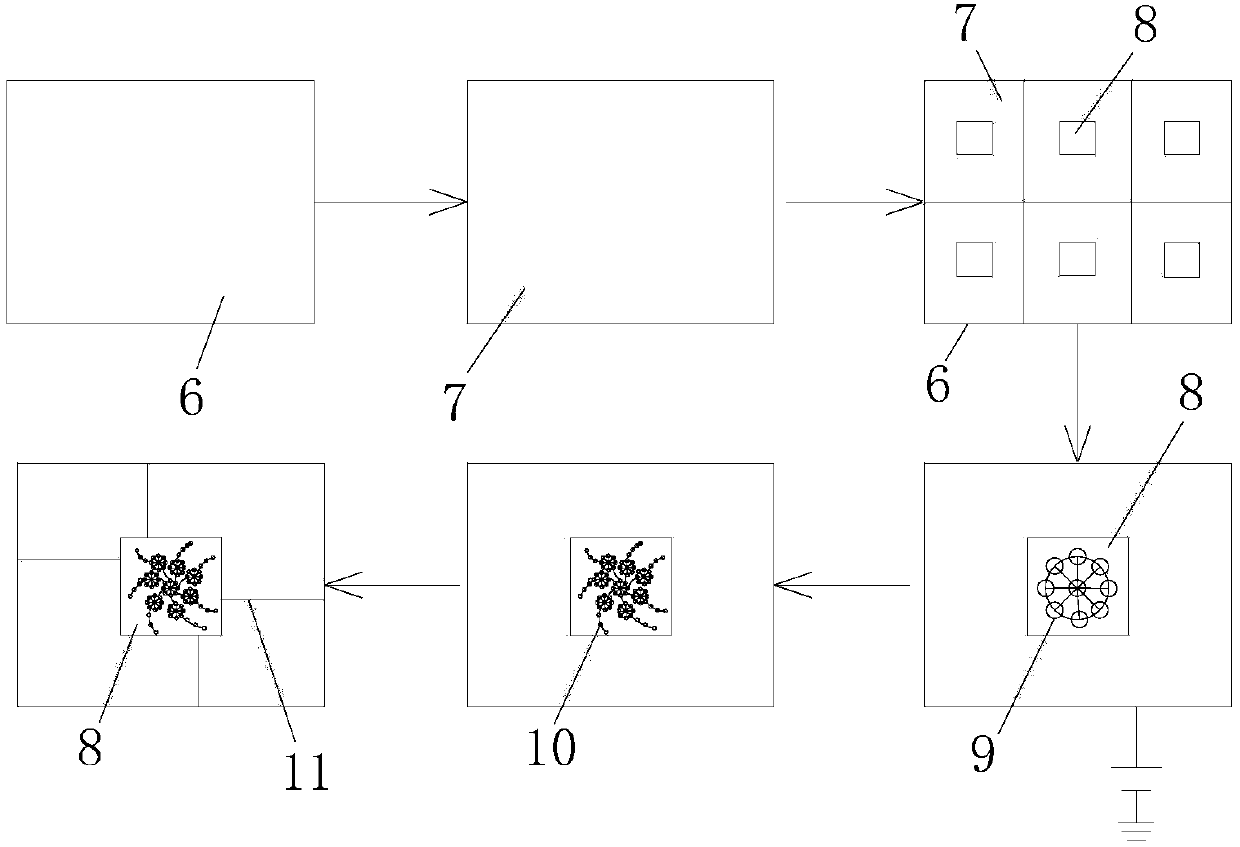

[0039] Embodiment 2, with reference to figure 2 , the method for large-scale processing and integration of atomic-level devices, a large-scale cluster device processing scheme based on electrical guidance, the specific process is as follows,

[0040] 1), plating a layer of silver (Ag) film 7 on the substrate of the substrate 6;

[0041] 2), using photolithography and electron beam lithography to process a window 8 of 10×10 nanometers on the silver film 7;

[0042] 3), the Au 13 The (gold) cluster 9 is accelerated to 100 electron volts and deposited on the substrate 6, and a voltage of 100-105V is applied to the silver film 7 of the substrate 6 to ensure that the atomic cluster reaches the window 8;

[0043] 4), through Au 13 The selective adsorption of clusters 9 and thiols makes the entire substrate 6 lightly covered with a layer of thiols 10, and then washed away, under selective and molecular-level guidance, to form Au 13 The cluster 9 is connected to the thiol layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com