White mosquito-repellent incense and preparation method thereof

A mosquito-repellent incense and white technology, applied in botany equipment and methods, chemicals for biological control, insecticides, etc., can solve the problems of different specific gravity and combustion performance, easily dirty hands, and consume large green resources. Achieve the effects of stable product weight and burning time, simple production process, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

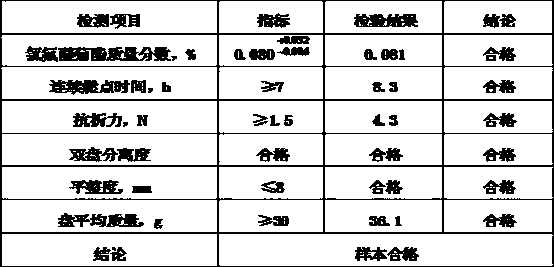

[0031] Embodiment 1 provides the preparation process of white mosquito coils, comprising the following steps:

[0032] 1, the making of mosquito-repellent incense dry billet: 5% cellulose ether, 8% methyl cellulose, 5% hydroxypropyl cellulose, 12% carboxymethyl cellulose, 10% bone meal , 17% of light calcium carbonate, 28% of talcum powder and 15% of sweet potato slag powder are added to the powder mixer for pre-mixing for 30 minutes, and then water with 0.6 times the weight of the powder is added for wet material mixing. The mixing time Generally controlled at about 15 minutes. After the stirring is completed, the wet material is punched and formed by the mosquito coil forming equipment, and then dried to obtain a white smokeless mosquito coil.

[0033] 2. The configuration of the mosquito-repellent incense: add 5% of the chlorofluoromethrin technical product, 4% of the essence and 91% of the deodorized kerosene into the stirring tank and stir for 30 minutes according to the...

Embodiment 2

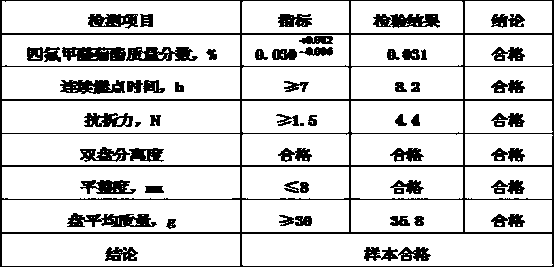

[0048] Embodiment 2 provides the preparation process of white mosquito coils, comprising the following steps:

[0049] 1. The production of mosquito-repellent incense dry base: 6% cellulose ether, 6% hydroxyethyl cellulose, 8% hydroxypropyl cellulose, 12% carboxymethyl cellulose, 12% Bone meal, 18% light calcium carbonate, 25% talcum powder and 13% sweet potato slag powder are added to the powder mixer for pre-mixing for 30 minutes, and then water with 0.7 times the weight of the powder is added for wet material mixing, stirring The time is generally controlled at about 15 minutes. After the stirring is completed, the wet material is punched and formed by the mosquito coil forming equipment, and then dried to obtain a white smokeless mosquito coil.

[0050] 2. The configuration of the mosquito-repellent incense: add 1.8% perfluthrin technical, 4% essence and 94.2% deodorized kerosene into the stirring tank and stir for 30 minutes to complete the preparation of the liquid medi...

Embodiment 3

[0056] 1. The production of mosquito-repellent incense dry base: 15% hydroxyethyl cellulose, 10% hydroxypropyl cellulose, 15% carboxymethyl cellulose, 18% light calcium carbonate, 25% The talcum powder and 17% sweet potato slag powder are added to the powder mixer for pre-mixing for 30 minutes, and then water 0.6 times the weight of the powder is added for wet material mixing. The mixing time is generally controlled at about 15 minutes. After the stirring is completed, the wet material is punched and formed by the mosquito coil forming equipment, and then dried to obtain a white smokeless mosquito coil.

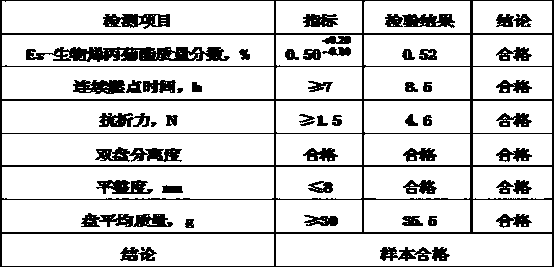

[0057] 2. The configuration of mosquito-repellent incense medicament: add 30% Es-bio-allethrin technical material, 4% essence and 66% deodorized kerosene into the stirring tank and stir for 30 minutes respectively by weight to complete the preparation of the liquid medicine.

[0058] 3. Spraying and packaging: Spray 0.6 grams of each piece of dry blank prepared in advance, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com