Melt testing apparatus having elevating chassis

A test device and melting technology, which can be used in nuclear reactor monitoring, reactors, nuclear power generation, etc., and can solve problems such as difficulty in taking out solid blocks and shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

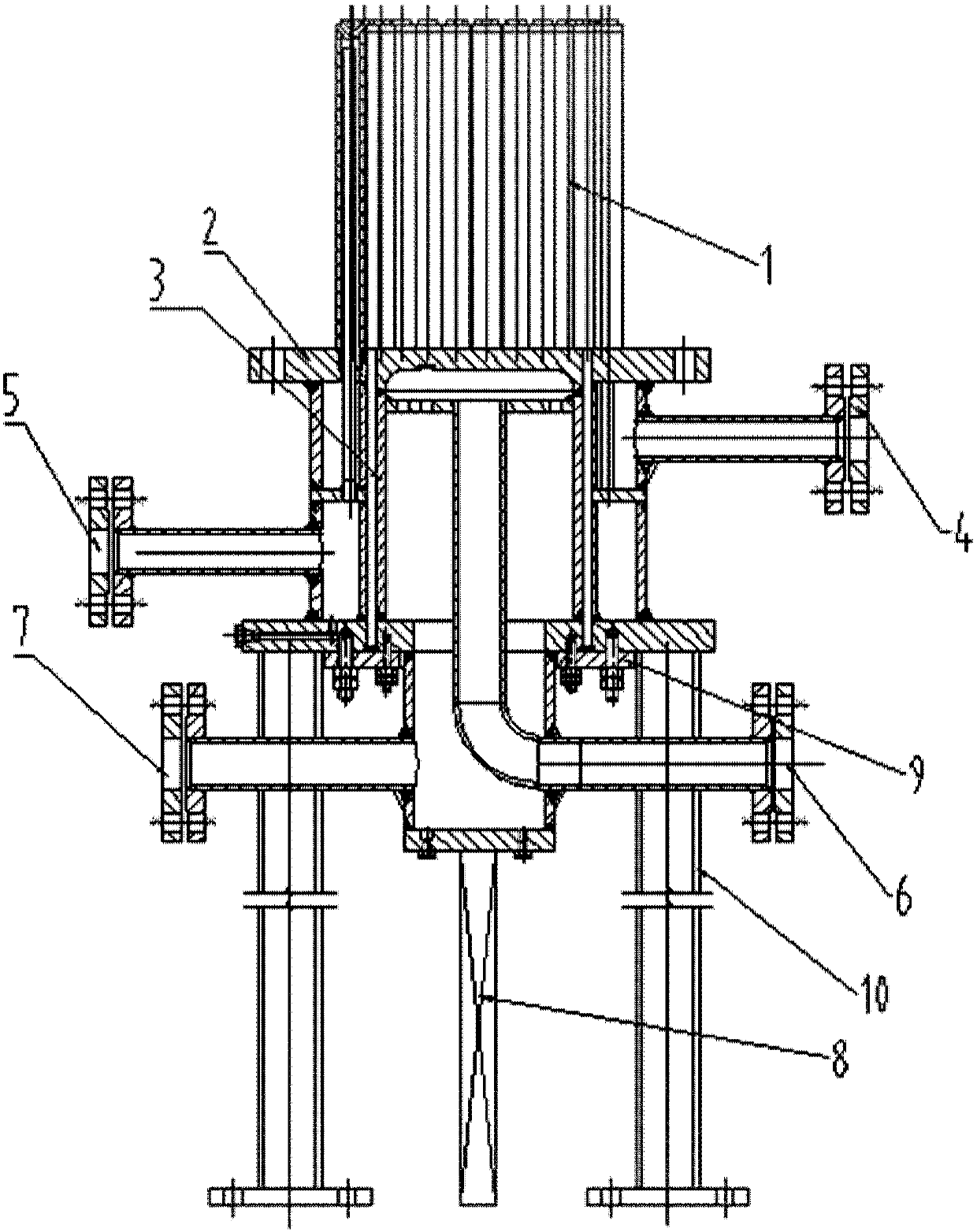

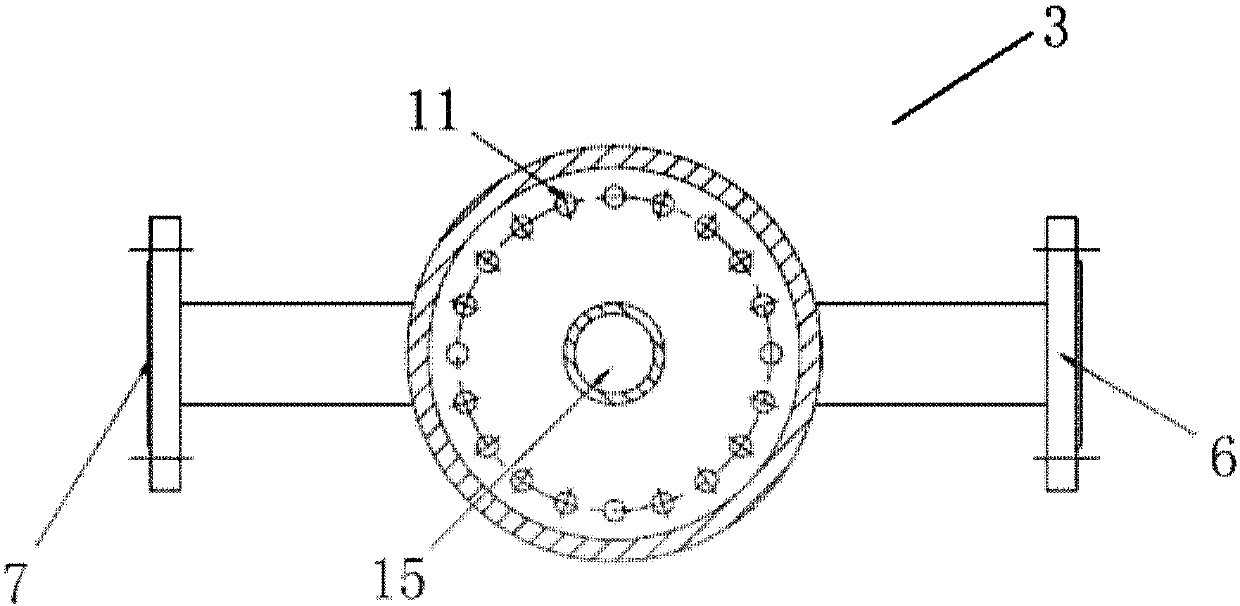

[0035] Through a specific example, a test section for studying the cooling characteristics of the surface of the molten pool is described in detail, which mainly includes a cold crucible, an induction heating coil, and a chassis lifting mechanism. The cold crucible is straight and consists of two parts, the bottom water-cooled chassis and the vertical water-cooled casing, which are used to hold the zirconia melt (2700-3000°C), and provide a cooling boundary for the molten pool to form a zirconia dense shell. The inner diameter of the crucible is 220mm. The material of the water-cooling sleeve is copper, and the outer tube length of the water-cooling tube of the water-cooling sleeve is 450mm, which is circularly arranged on the base of the outer chassis in a straight cylinder shape, and the distance between the copper tubes is 1-2mm. The inner and outer pipes are connected to the base by threads, which is convenient for disassembly and replacement. The upper end of the outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com